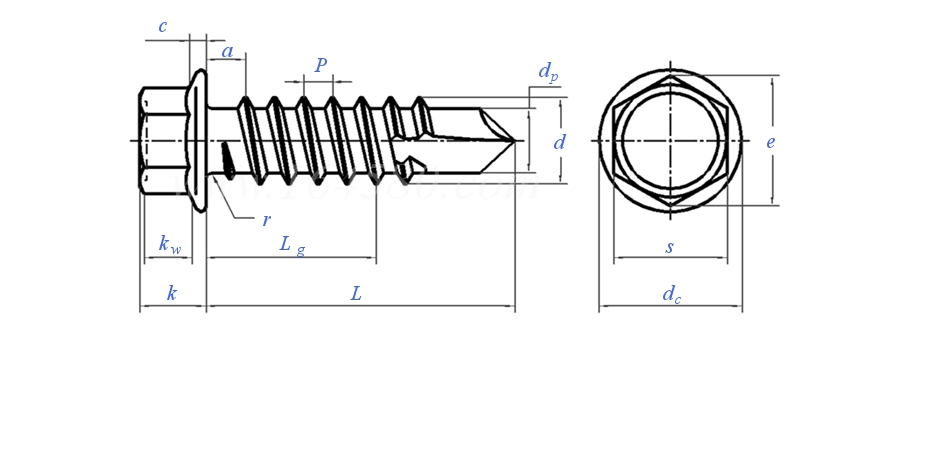

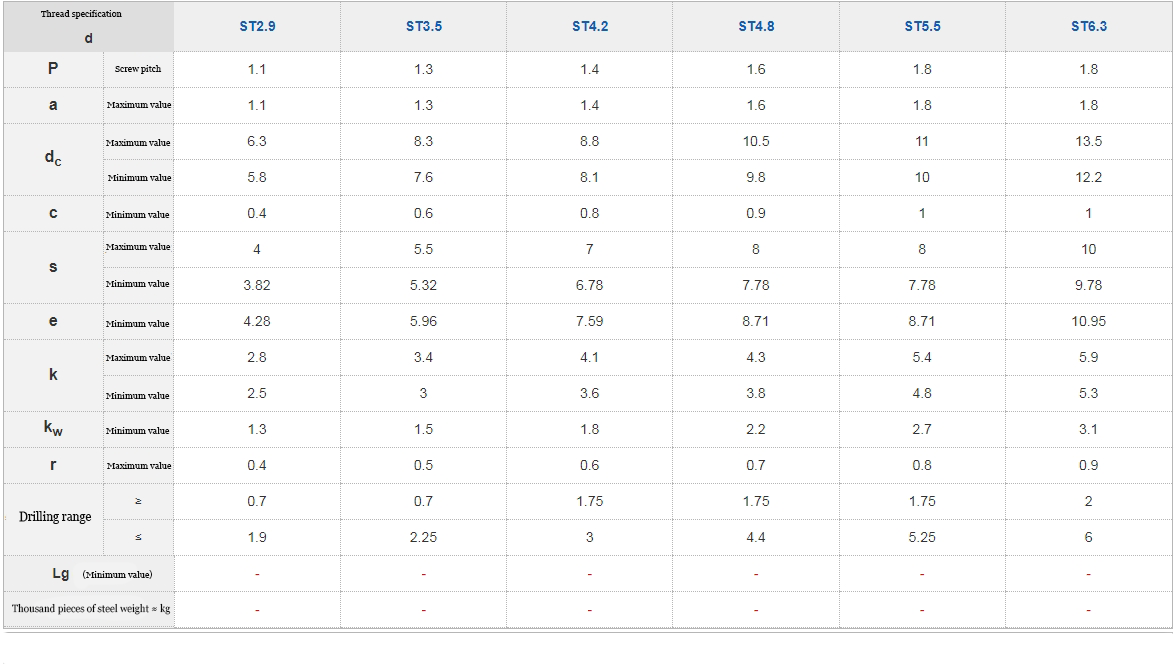

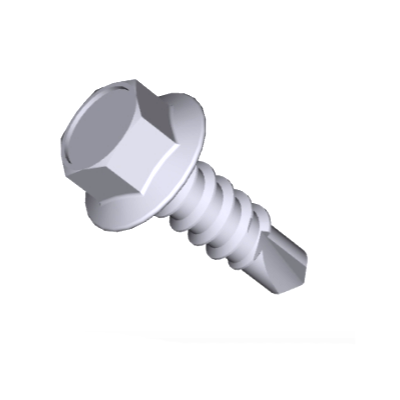

Hexagonal flange self drilling self tapping screws are a multifunctional fastener with the characteristics of self drilling and self tapping. According to the GB/T15856.4-2002 standard, hexagonal flange self drilling self tapping screws consist of threaded areas and hexagonal flange surfaces with the same diameter. It can automatically drill holes and install itself on the surface of the substrate through self tapping threads, without the need for prefabricated holes and nuts, improving construction efficiency.

What are the characteristics of hexagonal flange self drilling and self tapping screws?

1. Quick construction: Hexagonal flange self drilling and self tapping screws do not require pre drilling and installation of nuts, and can be tightened with only a screwdriver or wrench, greatly saving construction time.

2. Excellent tensile strength: Hexagonal flange self drilling self tapping screws are made of high-strength steel with reasonable thread design, which can provide excellent tensile strength and ensure the reliability of fasteners during use.

3. Excellent rust prevention performance: Hexagonal flange self drilling self tapping screws have been galvanized or stainless steel surface treated, which has excellent rust prevention performance and can effectively prevent rust during use, extending the service life of fasteners.

4. Wide application range: Hexagonal flange self drilling self tapping screws are suitable for connecting different substrates such as steel and wood, and are widely used in fields such as construction, furniture, and automobiles.

What are the application scenarios of hexagonal flange self drilling and self tapping screws?

1. Construction field: Hexagonal flange self drilling self tapping screws are commonly used in steel structure construction, roof fixing, wall decoration and other construction. The characteristic of rapid construction can greatly improve project progress and construction efficiency.

2. Furniture field: Hexagonal flange self drilling self tapping screws play an important connecting role in furniture manufacturing. It can quickly fix furniture components, provide stable connections, and ensure the safety of furniture use.

3. Automotive field: Hexagonal flange self drilling self tapping screws are widely used in automotive manufacturing and repair. It can be used to fix car bodies and components, with good tensile strength and rust resistance, improving the safety and durability of cars.

4. Other fields: Hexagonal flange self drilling self tapping screws can also be used in electronic equipment, household appliances, mechanical equipment and other fields to meet the fastening needs in different fields.

The problems and solutions of hexagonal flange self drilling and self tapping screws

1. Poor drilling quality: When using hexagonal flange self drilling self tapping screws, if the base material is hard or the pre drilling is incorrect, it can easily lead to poor drilling quality and affect the fixing effect of the screws. The solution is to use professional screw drilling tools to ensure drilling quality.

2. Uneven locking force: Due to the operator's uneven force during the tightening process, the locking force of the hexagonal flange self drilling self tapping screw may be uneven. The solution is to use a torque wrench for locking, ensuring that each screw is within the appropriate locking force range.

3. Environmental corrosion impact: In special environments, hexagonal flange self drilling self tapping screws may be affected by corrosion, reducing their rust resistance and service life. The solution is to choose corrosion-resistant screws suitable for special environments or take additional protective measures.