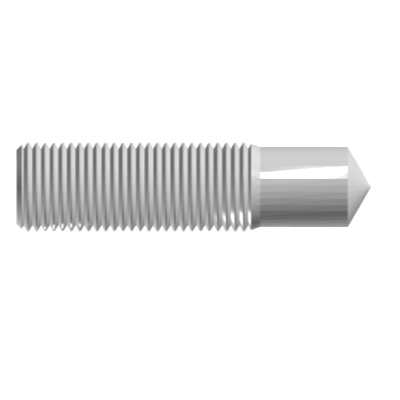

Welding bolts refer to the method of welding metal bolts or similar metal components (bolts, nails, etc.) to the workpiece, which is called bolt welding. The bolts used for welding here are called welding bolts.

Used for connecting thinner components to steel plates, with the unthreaded end welded to the component. There are two types of welding bolts for manual welding and welding bolts for power arc welding.

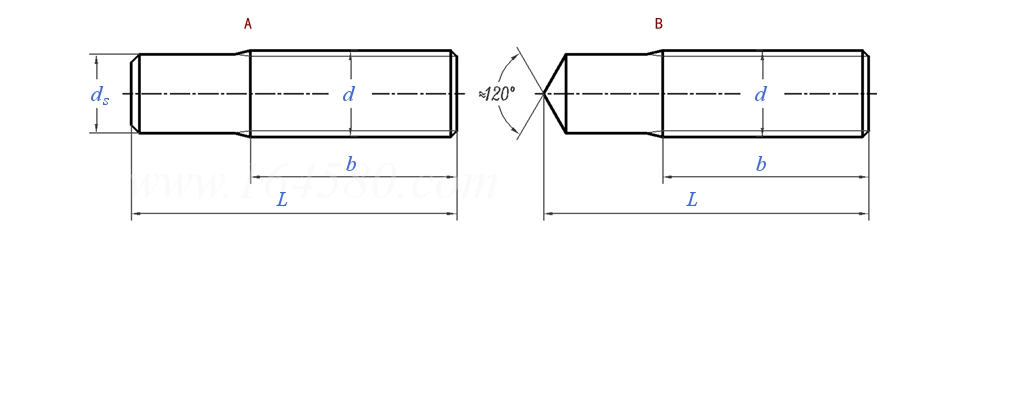

The methods for welding bolts include resistance welding, friction welding, explosive welding, and arc welding. The diameter of the welded bolts is generally:

Stud welding characteristics:

1. Very time and cost saving

All bolt welding structures do not require drilling, punching, threading, riveting, threading, and finishing steps.

2. Continuously expanding the application potential of structural design

The welding process during screw welding is short in time, with high current and small penetration depth. Therefore, it can be welded to very thin sheets. The thickness of the plate using ceramic ring arc welding and short cycle arc welding can reach 1mm. The capacitance discharge pull arc screw welding can reach up to 0.6mm, while the energy storage type screw can reach up to 0.5mm.

The workpiece for screw welding must be welded from one side.

It can be welded in all positions, and with the help of an expander, it can be welded to restricted vertical partitions.

Due to the short duration of welding and minimal deformation after welding, there is no need for repair.

Because the welded structure does not require drilling, it will not cause leakage.

The joint welded with bolts can achieve high strength, that is, the strength of the joint welded with bolts is greater than the strength of the bolts themselves.

After welding the coating or high alloy plate, there are no imprints on the back.

3. Good economy

The advantage of screw welding over other welding methods lies in the welding power. For mass-produced workpieces, they can be welded up to 8-40 pieces/min in a very short welding time (3-980ms) (depending on different diameter bolts and welding power). The automatic feeding screw welding machine can achieve ultra-high efficiency of 60 pieces/min.

Standard bolts are low-cost.

There are various types of screw welding equipment and welding guns, and the purchase cost of the equipment is relatively low.

According to the product, it can be made into multi station automatic welding machines or high-precision gantry CNC automatic welding machines.

Stud welding has a high quality reproduction rate and a small scrap rate.