The expansion bolt is a special threaded connector used to fix the pipe support/lift/bracket or equipment on the wall, floor or column. The grades of carbon steel bolts are divided into 3.6,4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9 and other more than 10 grades.The numbers before and after the decimal point respectively indicate the nominal tensile strength and yield ratio of the bolt material, for example: marking 8.8 bolts indicates that the tensile strength of the material reaches 800MPa, and the yield strength is 0.8, that is, its yield strength reaches 800x0.8=640MPa.

Materials:

The grades of expansion bolts are divided into 45, 50, 60, 70 and 80.The material is mainly divided into austenite A1, A2, A4;Martensite and ferrite C1, C2, C4;Its representation, e.g. A2-70;"-" before and after indicates bolt material and strength grade respectively.(1) Bolt material commonly used materials: Q215, Q235, 25 and 45 steel, for important or special purpose threaded connection parts, can choose 15Cr, 20Cr, 40Cr,15MnVB, 30CrMrSi and other high mechanical properties of alloy steel.(2) Allowable stress The allowable stress of the threaded connection is related to the load nature (static, variable load), whether the connection is tightened, whether the preload needs to be controlled, and the material and structural size of the threaded connection.

sort:

The grade of stainless steel bolts is divided into 45, 50, 60, 70, 80, the material is mainly divided into austenite A1, A2, A4, martensite and ferrite C1, C2, C4, its expression method such as A2-70, "one" before and after respectively indicate the bolt material and strength grade.

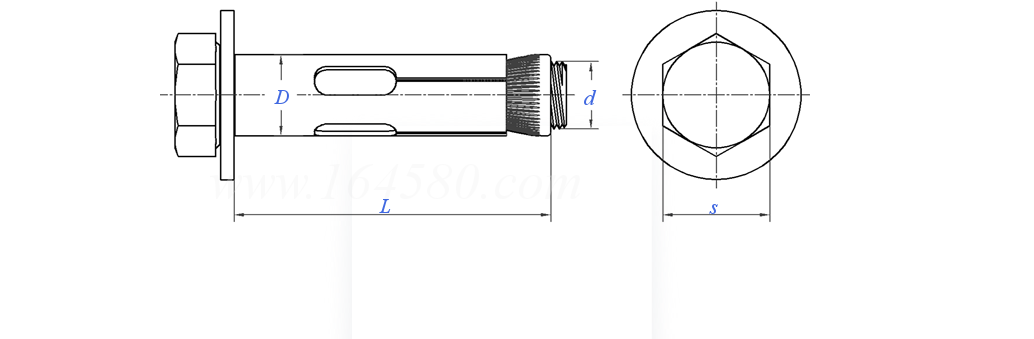

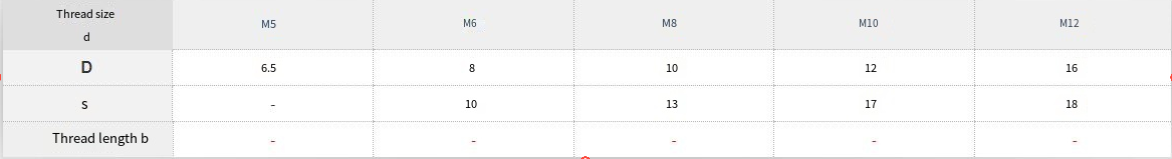

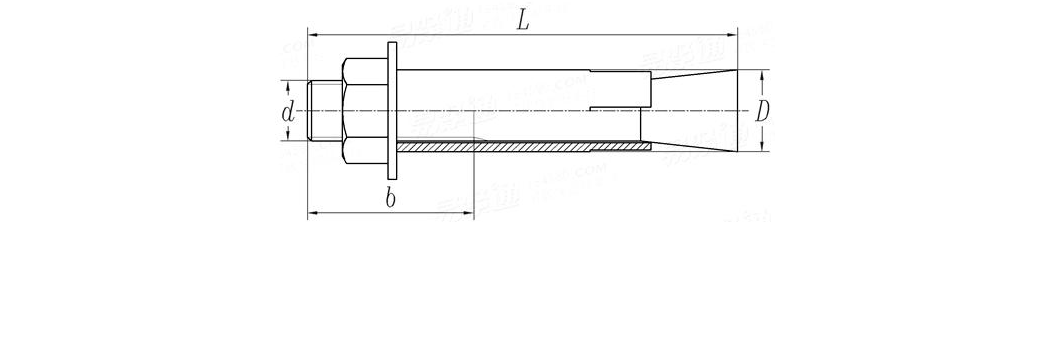

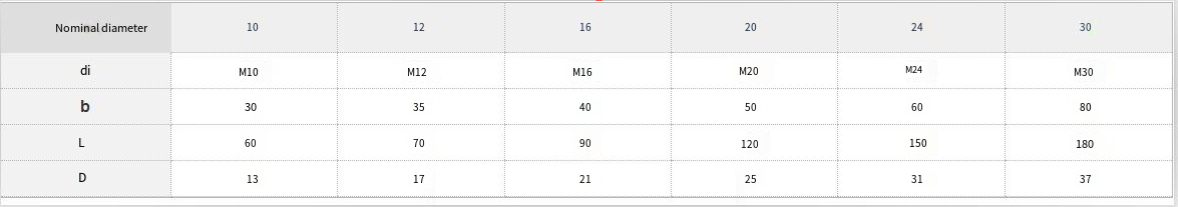

constitute:The expansion bolt consists of a countersunk bolt, an expansion tube, a flat washer, a spring washer, and a hex nut.

When in use, it is necessary to drill a hole of the corresponding size on the fixed body with an impact drill (hammer), and then put the bolt and expansion tube into the hole, and tighten the nut to make the bolt, expansion tube, installation part and the fixed body expand tightly into one.After tightening will expand, the bolt tail has a big head, the bolt outside set a slightly larger than the diameter of the bolt round pipe, the tail part has several openings, when the bolt is tightened, the tail of the big head will be taken to the opening of the pipe inside, the pipe big, to achieve the purpose of expansion, and then the bolt fixed on the ground or the wall, to achieve the purpose of rooting.

Performance class 4.6 expansion bolts, meaning:1, the nominal tensile strength of the expansion bolt material reaches 400MPa level;2. The flexion ratio of the expansion bolt material is 0.6;3, the nominal yield strength of the expansion bolt material is 400x0.6=240MPaThe meaning of the performance level of the expansion bolt is an international standard, the same performance level of the expansion bolt, regardless of the difference in material and origin, its performance is the same, the design can only choose the performance level.

Matters needing attention:

1, punching depth: the depth of the specific construction is best than the length of the expansion tube about 5 mm. As long as it is greater than or equal to the length of the expansion tube, the length of the internal expansion bolt remaining in the ground is equal to or less than the length of the expansion tube.2, the requirements of the internal expansion bolt on the ground, of course, the harder the better, it also depends on the force of the object you need to fix. The force strength installed in concrete (C13-15) is five times that in the brick body.3. After correctly installing an M6/8/10/12 inner expansion bolt in concrete, its optimal maximum static force is 120/170/320/510 kg respectively. The installation method of the inner expansion bolt is not very difficult, the specific operation is as follows; First choose an alloy drill bit with the same diameter as the expansion ring (tube) of the expansion screw, install it on the electric drill and then carry out wall drilling, the depth of the hole is best the same as the length of the bolt, and then put the expansion screw kit down to the hole, remember; Do not screw off the screw, to prevent the hole drilling is relatively deep when the bolt fell into the hole and not good to take out. Then screw the screw screw 2-3 buckle after feeling the inner expansion bolt is tight but not loose and then screw off the screw screw.