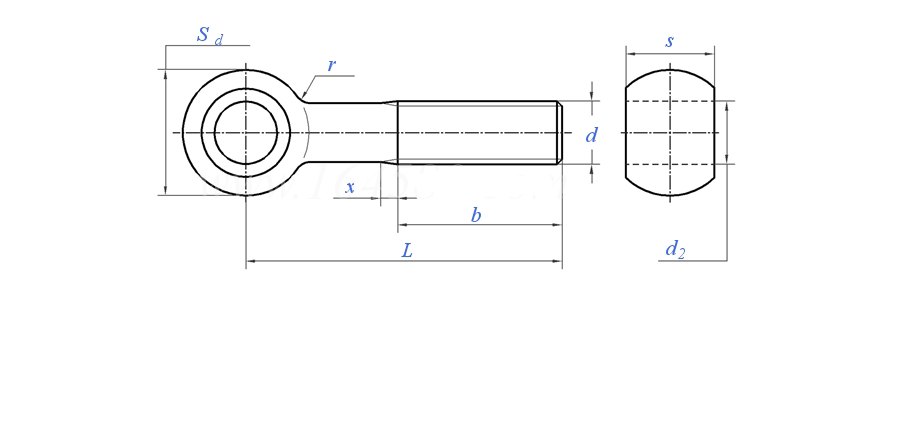

Knuckle bolts, also known as hole bolts in China, comply with GB/T798-88 standard; Also known as fisheye bolt abroad, it follows DIN444 standard. Refined hole bolt, smooth spherical surface, high thread accuracy, thread specifications from M6 to M64. The surface treatment of the bolt is: hot-dip galvanizing, oozing plating, white plating, color plating and other anti-corrosion measures, the factory color of the high-strength bolt is boiling black hair blue, the material is: Q235, 45#, 40Cr, 35CrMoA, stainless steel 304 and stainless steel 316 and so on. Application items: filter type self-rescue device, gas detection instrument, dust mask, mining raincoat, mine explosion device, application details: bolts are widely used in: Low temperature and high pressure valves, pressure pipelines, fluid engineering, oil drilling and production equipment, oilfield equipment and other fields, often in the disconnecting occasions or tools such as the valve industry, folding bicycles, strollers are used, because the use of bolts is convenient and fast, and the use of matching nuts to connect and tighten the role, a wide range of applications. For the valve bolt, the sealing problem can not be ignored, because the valve run, leakage, dripping and other phenomena come from here, we must ensure the quality of the valve bolt, in order to ensure the safety of use.

Shi RengoJoint bolt is a common mechanical connection, widely used in a variety of mechanical equipment and structures, its role is through the combination of bolts and nuts, the two or more parts are closely connected together, play a fixed and supporting role. Knuckle bolts have an important position in the engineering field, which will be introduced in detail below.Definition and structure of joint boltsA jointed bolt is a connecting piece composed of a bolt and a nut, which is characterized by the connection of the screw part and the nut part through the teeth, so that it has a certain mobility. Screw bolt is mainly composed of screw, nut and screw, screw one end has a thread, the other end has a connecting part, the connecting part has a groove, used to install the screw, nut is used with screw thread connection parts, screw is the key part of the connection screw and nut, its role is to enable the bolt to carry out activities within a certain range.Two, the advantages and applications of boltsJoint bolts have the following advantages:1. The gap between the connecting parts can be adjusted within a certain range to adapt to the assembly requirements of different sizes.2. Due to the existence of the joint, the joint bolt can absorb vibration and shock, and improve the seismic performance of the connector. 3. Coupling bolts are more convenient for disassembly and maintenance, and will not damage the connecting parts.Joint bolts are widely used in the engineering field, especially for occasions that require frequent disassembly and adjustment, such as mechanical equipment, ships, Bridges, highway guardrail and so on. The flexibility and adjustability of the joint bolt make it an important part of a variety of large equipment and structures.Third, the use of bolts precautionsWhen using the bolt, the following points need to be noted:1. Select the appropriate type and material of the bolt based on the actual application scenario and requirements.2. During assembly, ensure that the thread of the bolt and nut matches, and the connection fastening force is moderate, not too tight or too loose. screw3. Check the joint bolt regularly during use to ensure that the bolt and nut are connected in good condition. If loose or damaged, replace it in time.4. When disassembling, use appropriate tools and methods to avoid damaging bolts and nuts.Four, the development trend of boltsWith the continuous development of engineering technology and the improvement of requirements, the performance and quality of knuckle bolts are also improving. At present, some international standards have developed technical specifications and test methods for knuckle bolts, which provide a reference for the production and application of knuckle bolts. In the future, knuckle bolts will pay more attention to the research and development and optimization of materials to improve their corrosion resistance and fatigue resistance. To adapt to more complex and harsh working environments.Joint bolt as a common mechanical connection, in the field of engineering plays an important role, its structure is simple, easy to use, with good adjustable and seismic performance, in practical applications, we need to pay attention to select the right type and material, and strictly in accordance with the requirements of the installation and maintenance, to ensure the reliability and safety of joint bolts. In the future, the development of knuckle bolts will pay more attention to the improvement of performance to meet the changing engineering needs