Spherical washers have a locking effect. When tightening, there is stress in the axial direction of the bolt, which increases the friction force between the threads. This configuration ensures that the object being tightened is not easily loosened. Washers are divided into: Flat Washers - Class C, Large Washers - Class A and C, Extra Large Washers - Class C, Small Washers - Class A, Flat Washers - Class A, Flat Washers - Chamfer Type - Class A, High strength Washers for Steel Structures, Spherical Washers, Conical Washers, Square Diagonal Washers for I-beams, Square Diagonal Washers for Channel Steel, Standard Spring Washers, Light Spring Washers, Heavy Spring Washers, Inner Serrated Lock Washers, Outer Serrated Lock Washers, and Outer Serrated Lock Washers Single ear stop washer, double ear stop washer, outer tongue stop washer, and stop washer for round nuts.

The function of spherical washers

Spherical gasket is a commonly used sealing element installed at the connection between two mechanical parts, achieving sealing through spherical contact. Its function is to form an effective seal between two parts, prevent medium leakage, and be able to withstand certain working loads.

The difference between different types of spherical washers

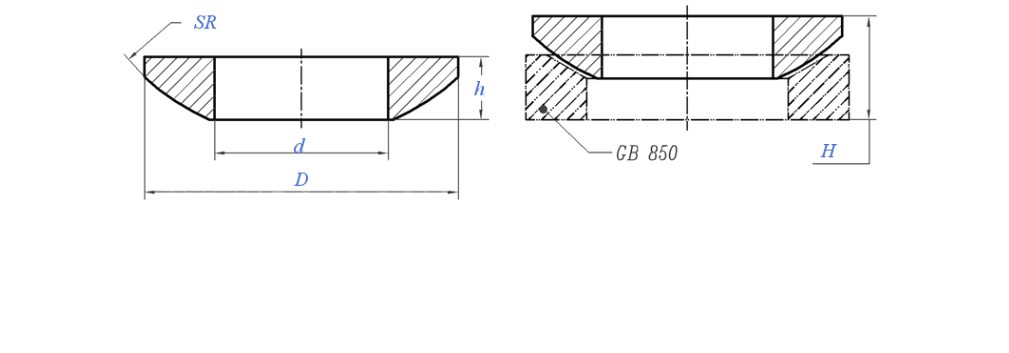

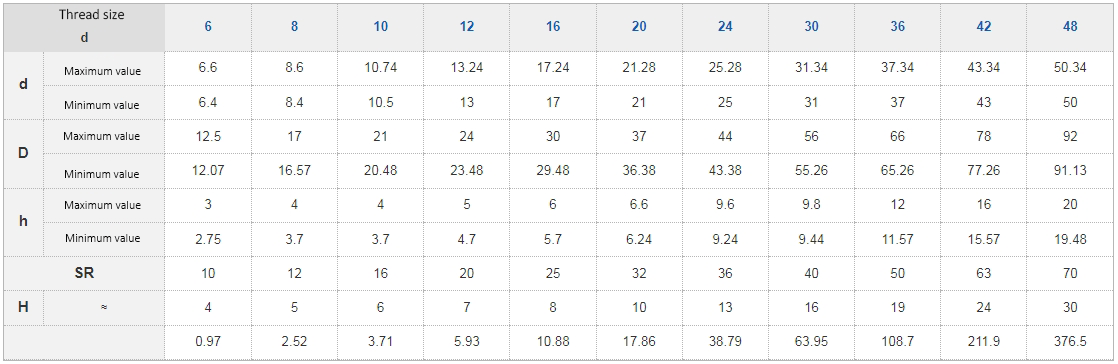

1. In terms of shape and structure: The shape and structure of spherical washers can be divided into circular, square, etc., among which circular is more common. In addition, spherical washers can be divided into inner spherical washers and outer spherical washers based on their connection with other components.

2. Material aspect: The sealing performance, wear resistance, and corrosion resistance of spherical washers are directly related to their material. Common materials for spherical washers include rubber, polyurethane, polyester film, fluororubber, etc. Different materials of spherical washers are suitable for different working environments.

3. Application scenarios: Due to the sealing performance of spherical washers, they are widely used in fields such as machinery, chemical industry, food, medical devices, etc. There are also significant differences in the required spherical washers in different scenarios.

How to correctly select spherical washers

The correct selection of spherical washers requires consideration of the following aspects:

1. Working environment: Select appropriate materials and sealing methods according to the requirements of the working environment.

2. Working temperature: The performance of spherical washers varies at different temperatures, so it is necessary to choose the appropriate material based on the specific working temperature.

3. Work pressure: Select spherical washers with corresponding pressure bearing capacity according to the required work pressure.

4. Surface roughness: When selecting spherical washers, the roughness of the mating surface should also be considered to ensure the fitting effect between the washer and the mating components.