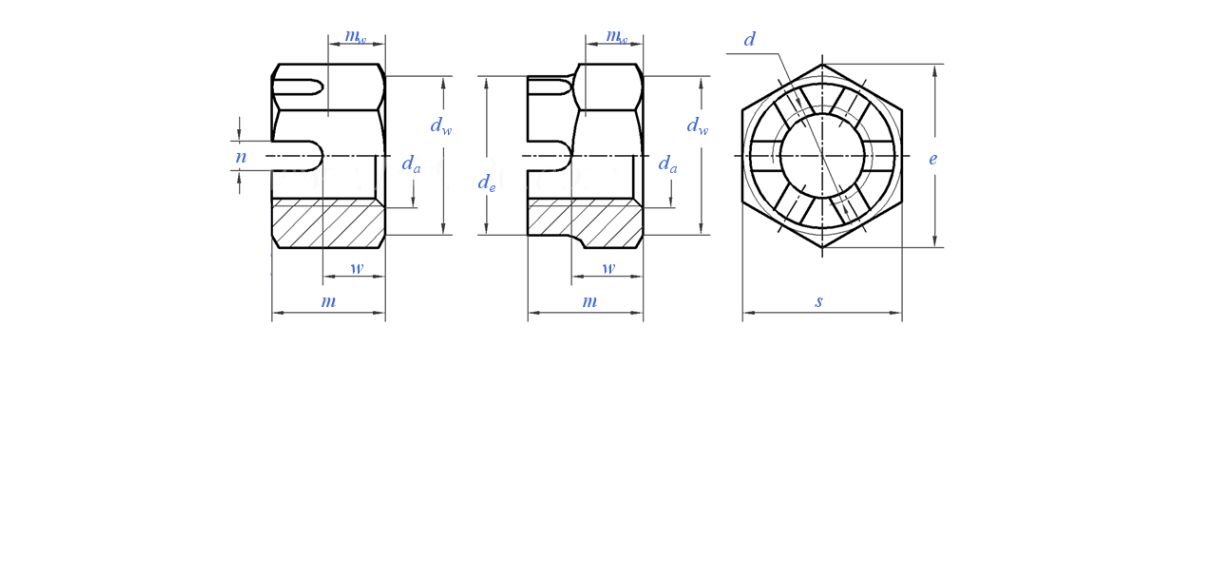

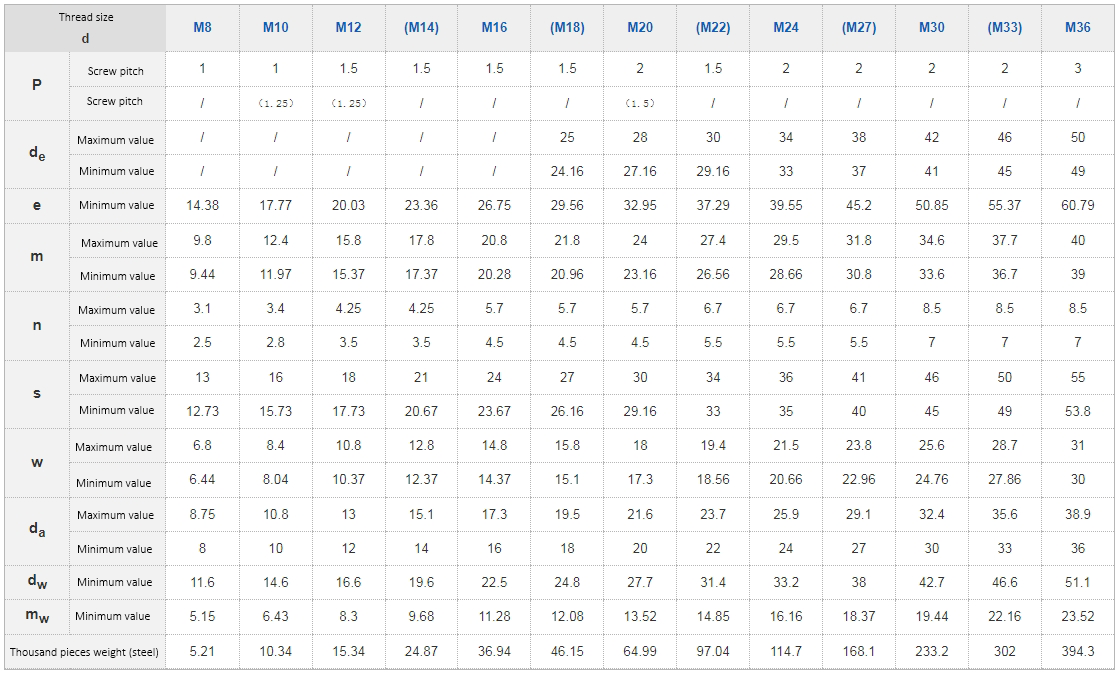

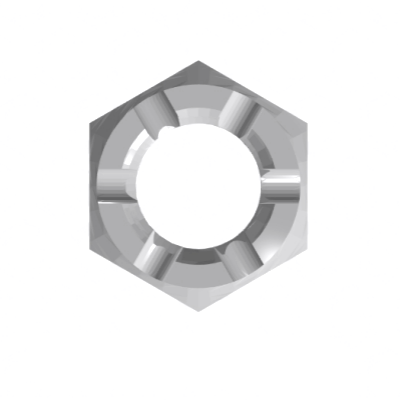

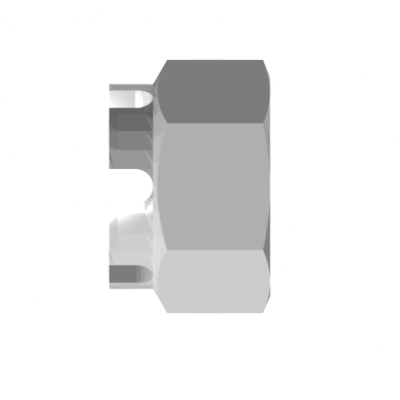

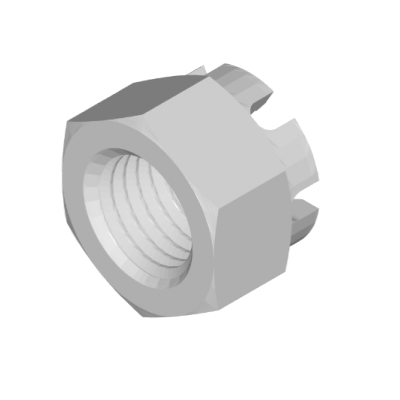

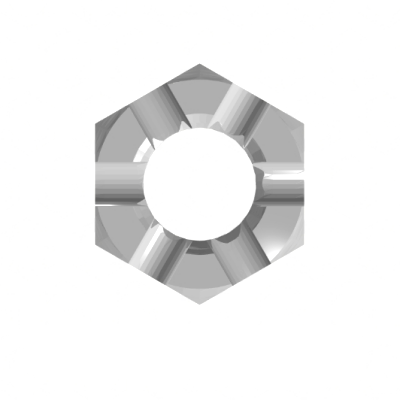

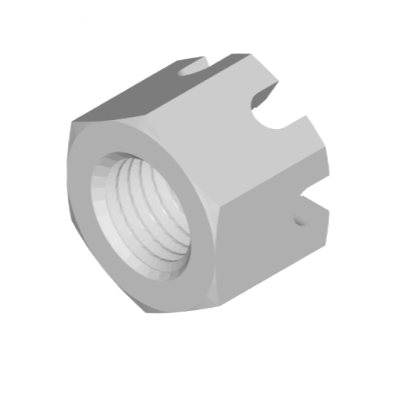

Slotted nuts mainly refer to hexagonal slotted nuts, that is, grooves are machined above the hexagonal nuts. It is used in conjunction with threaded bolts with holes and split pins to prevent relative rotation between bolts and nuts

Hexagonal slotted nuts are very common in daily hardware stores, and there are also many places where hexagonal slotted nuts are used. But how much do you know about them? Let's now provide a detailed introduction to the types and uses of hexagonal slotted nuts! Hexagonal slotted nuts can be divided into three types based on thickness: Type 1, Type 11, and Thin. Grade 8 nuts are divided into two types: Type 1 and Type 11. Type 1 hexagonal slotted nuts are widely used. Type 1 nuts are divided into three levels: A, B, and C. Among them, A, B, and B level nuts are suitable for machines, equipment, and structures with lower surface roughness and high precision requirements, while C level nuts are used for machines, equipment, or structures with relatively rough surfaces and low precision requirements; The thickness of type 2 hexagonal slotted nuts is relatively thick, and they are often used in situations that require frequent assembly and disassembly. Type 1 nuts refer to ordinary hexagonal slotted nuts with a nominal height of m20.8D, and their dimensions should comply with the provisions of GB/T6170; The height of type 2 nuts is higher than that of type 1 nuts, and their dimensions should comply with GB/T6175. The purpose of adding Type 2 nuts is twofold: firstly, to obtain a relatively inexpensive nut that does not require heat treatment by increasing the height of the nut. Because DsM16's Grade 8 Type 1 nuts do not require heat treatment, only the specifications with D>M16-39 use Type 2 nuts in Grade 8 nuts. Obviously, using Type 1 nuts without heat treatment cannot meet the mechanical performance requirements of Grade 9 nuts. Another purpose of specifying type 2 nuts is to obtain grade 12 nuts with good toughness. Due to the increase in height of the nut, the guaranteed stress index can be achieved at lower quenching and tempering hardness, thus increasing the toughness of the nut. The commonly used national standards for nuts are GB41 Type 1 hexagonal slotted nuts - C-grade GB6170 Type I hexagonal slotted nuts - A, B-grade GB61711 hexagonal slotted nuts - fine tooth - A, B-grade GB6172 hexagonal thin nuts - A, B-grade - chamfered GB6173 hexagonal thin nuts - fine tooth - A, B-grade GB6174 hexagonal thin nuts - B-grade - chamfered GB61751 hexagonal slotted nuts - A, B-grade GB61761 hexagonal slotted nuts - fine tooth - A, B-grade GB6177 hexagonal flange nuts - A, Grade GB56 hexagonal thick nut GB1229 large hexagonal slotted nut.