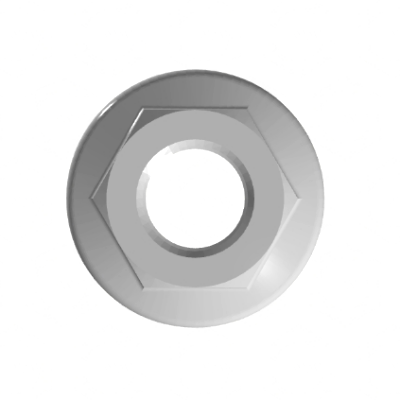

The hexagonal flange nut mainly includes a nut body, with a flange face fixed at one end of the nut body and a cover cap fixed at the other end of the nut body. It has good sealing and anti-corrosion properties.

Due to the installation of a cover cap on the nut body, the hexagonal flange nut has good sealing performance when used, which can effectively prevent harmful substances such as rainwater, moisture, and dust from immersing in the nut body, prevent rusting of the nut body, and greatly extend the service life of the hexagonal flange nut.

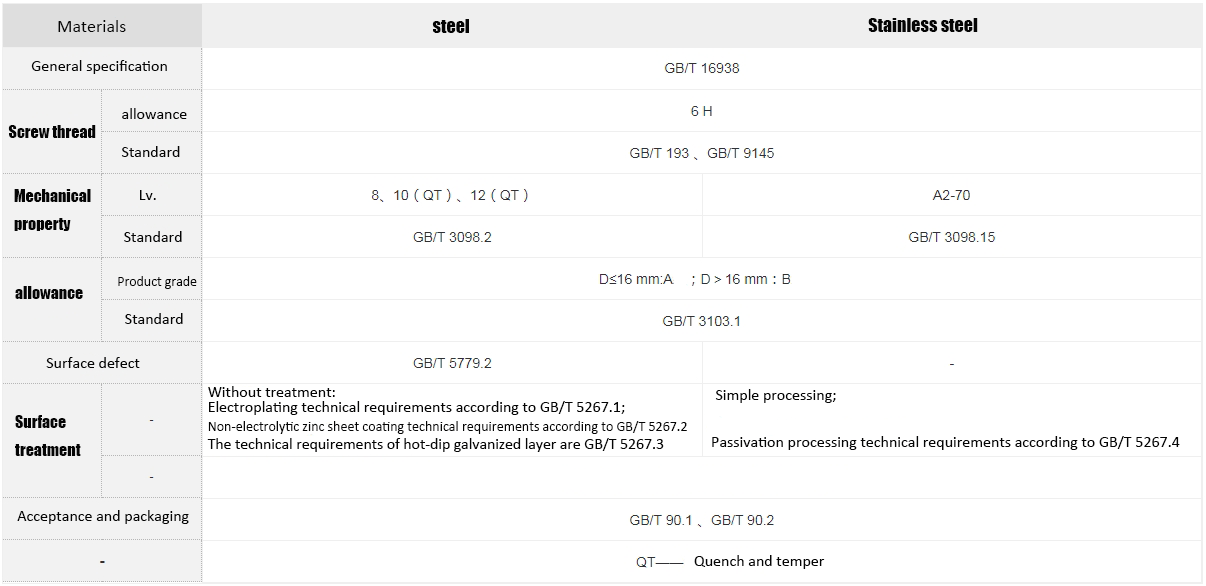

The characteristic of hexagonal flange welded nuts is that they have a regular shape with six hexagonal edges, which makes their torque more balanced and can withstand greater forces. At the same time, the design of the flange can make the connection tighter and less prone to loosening, thereby ensuring the safety and stability of the equipment. Welding is the main fixing method for hexagonal flange welding nuts. When welding, the flange part needs to be welded to the surface of the equipment, while the threaded part needs to be threaded and fixed with other connectors. Welding can make connections more secure and less prone to loosening, so hexagonal flange welding nuts are a common type of connection on equipment that needs to withstand greater pressure. The material of hexagonal flange welding nuts is usually high-strength alloy steel or stainless steel. This material can enhance the strength and corrosion resistance of the connectors, thereby extending their service life. At the same time, the selection of materials also needs to be adjusted according to different usage environments and requirements to ensure that the connectors can work normally under various harsh conditions. When using hexagonal flanges to weld nuts, it is necessary to pay attention to their tightening strength. If the connection is too tight, it can cause damage or deformation to the connecting parts; If the connection is too loose, it can lead to an unstable connection and affect the normal use of the device. Therefore, adjustments need to be made according to the actual situation during use to ensure the stability and safety of the connectors. Hexagonal flange welding nut is an important mechanical connector with good strength and corrosion resistance, suitable for connecting and fixing various mechanical equipment. During use, it is necessary to pay attention to its tightening strength to ensure the safety and stability of the equipment.