The outer edge of the screw head of an internal hexagonal screw is round, with a concave hexagon in the middle, and a hexagonal screw is a common type of screw head with a hexagonal edge. The hexagonal screwdriver looks like a "7". It is made by cutting and bending a hexagonal steel bar at both ends into a 90 degree angle to create an hexagonal screwdriver. It is available in hardware tool stores.

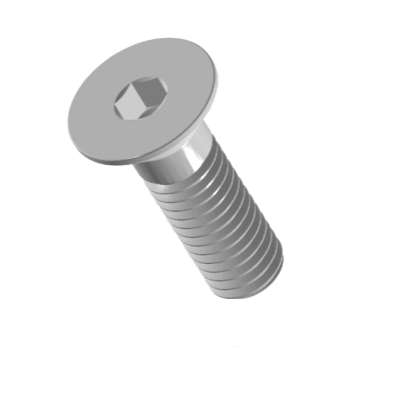

Countersunk hexagonal bolts, also known as flat cup hexagonal bolts, are commonly used in both imperial and metric systems and are made of commonly used materials

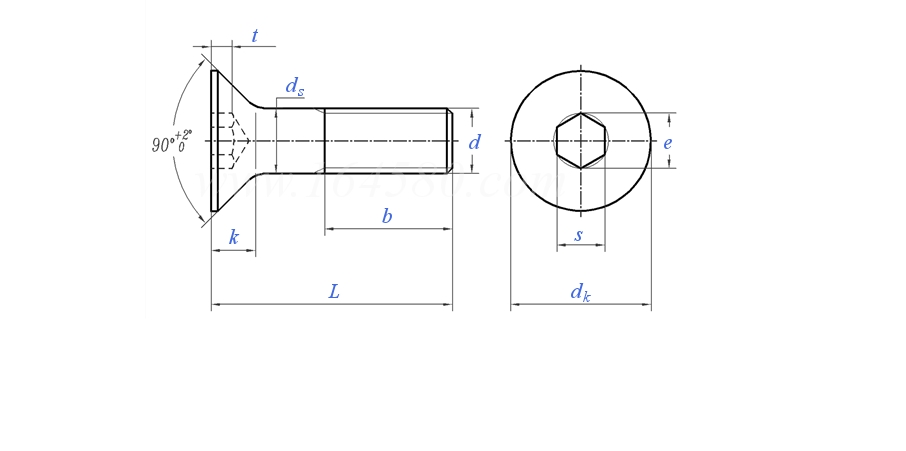

There are stainless steel and carbon steel. The outer edge of the screw head is circular, with a concave hexagon in the middle. Its head is a 90 degree angle

After assembly, the screw head can be inserted into the assembly surface of the vertebral body, keeping the assembly surface neat.

Countersunk hexagonal bolts are often used in mechanical equipment, mainly for advantages such as fastening, disassembly, and not easy to slip corners.

Internal hexagonal wrenches are usually turned at a 90 degree angle, with one end long and the other short, and the shorter end used for screwing

When holding silk, holding the long side can save a lot of force and provide excellent fastening effect.

Multi use countersunk hexagonal bolts

After assembly, there should be no concave areas on the surface of the components, and there are two types of fasteners: thin and thick. In other words

Thicker, which means that the thickness of the tightened component is higher than the thickness of the head of the hexagon socket bolt. After tightening the screw, there is another one

A small portion of the threads did not enter the threaded hole. Under such circumstances, the hexagonal bolts can be tightened.

Usually, there is another type of situation where the thickness of the tightened component is lower than the height of the head of the countersunk hexagon bolt

This is commonly seen in sheet metal parts of mechanical equipment, such as the hinge of the chassis power supply and the connection between the door and the box shell.