Cylindrical head welding nail is the abbreviation for cylindrical head welding nail used for arc screw welding. It belongs to a high-strength and rigid connection fastener, mainly used in large public buildings and super high-rise buildings. Its main body is mostly steel reinforced concrete structures. In order to ensure good bonding between steel components and work together, the fastener cylindrical head welding nail is widely used in this field through many experiments and engineering applications. Industrial factory buildings, highways, railways, bridges, towers, automobiles, energy, transportation facilities, airports, stations, power stations, pipeline supports, lifting machinery, and other types of steel structures.

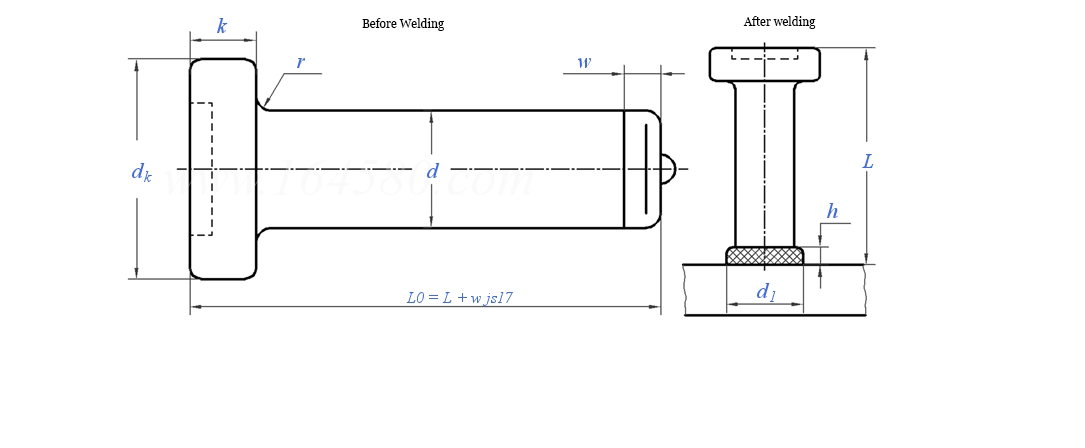

The specifications of cylindrical head welding nails are nominal diameter 10~ Ф 25mm, total length before welding 40-300mm.

The manufacturer of cylindrical head welding nails should use raised letters to mark the manufacturer's identification mark on the top surface of the head of the welding nail. For example, for cylindrical head welding nails with nominal diameter d=25mm, length l1=300mm, material ML15, and without surface treatment, the marking should be GB/T10433-2002 25 × 300. According to the national standard, the surface of cylindrical head welding nails should be free of rust, oxide skin, grease, and burrs. The rod of the cylindrical head welding nail shall not have cracks that affect its use, but the depth (radial) of the head crack shall not exceed 0.25 (dk-d) mm.

Pre weld inspection

(1) Before welding, the welding nails should be inspected and ensured to be free of rust, oxide skin, grease, moisture, or other defects that may affect the welding quality.

(2) The ceramic rings used for welding should be kept dry. If the packaging is damaged and causes the ceramic rings to become damp, they should be dried before welding at a temperature of 120 ℃ and insulated for two hours.

(3) There should be no harmful substances such as oxide skin, rust, or moisture that affect the welding quality within a range of 50mm at the welding point of the welding nail.

(4) When the length of the feeding wire is less than 50mm, its cross-section should not be less than 35mm2; At the same time, a dedicated power supply with sufficient capacity must be used, which is generally between 100KVA and 150KVA, and should be protected from rain and sun. The distribution box should be located near the bolt welding machine to facilitate quick disconnection of the power supply in case of a malfunction. The minimum distance between the welding machine body and the wall or other obstacles is 20cm to ensure air circulation around the welding machine and facilitate heat dissipation.

Welding construction

Before formal welding, welding nails and ceramic rings with the same specifications as the actual engineering requirements, as well as base materials with the same batch number and specifications (the thickness of the base material should not be less than 16mm and not more than 30mm) should be selected. The same welding method and position should be used for process parameter evaluation tests to determine the best matching relationship between welding current and welding time under the same conditions.

Additional use: Fasteners are a type of mechanical parts widely used for fastening connections. Various fasteners can be seen on various machinery, equipment, vehicles, ships, railways, bridges, buildings, structures, tools, instruments, instruments, and supplies. Its characteristics are a wide variety of specifications, diverse performance and uses, and a high degree of standardization, serialization, and generalization. For example, double headed screws: used to connect mechanical fixed links. Double headed screws have threads on both ends, and the middle screw can be thick or thin. They are called straight rods/shrink rods, also known as double headed bolts. Function: Generally used in mining machinery, bridges, automobiles, motorcycles, boiler steel structures, suspension towers, large-span steel structures, and large buildings.

Due to the specific requirements for the specifications, dimensions, tolerances, weight, performance, surface condition, marking method, acceptance inspection, marking, and packaging of each specific fastener product, they are separately specified in several national (industry) standards, such as English, German, and American. Fasteners are the most widely used mechanical foundation components. With China's accession to the WTO in 2001 and entering the ranks of international trading powers. Our country's fastener products are exported in large quantities to countries around the world, and fastener products from various countries around the world are also constantly entering the Chinese market. As one of the products with a large import and export volume in China, fasteners have important display and strategic significance in achieving international integration, promoting Chinese fastener enterprises to go global, and promoting their full participation in international cooperation and competition. Fastener is a general term for a type of mechanical component used to securely connect two or more parts (or components) into a single entity. Also known as standard parts in the market.