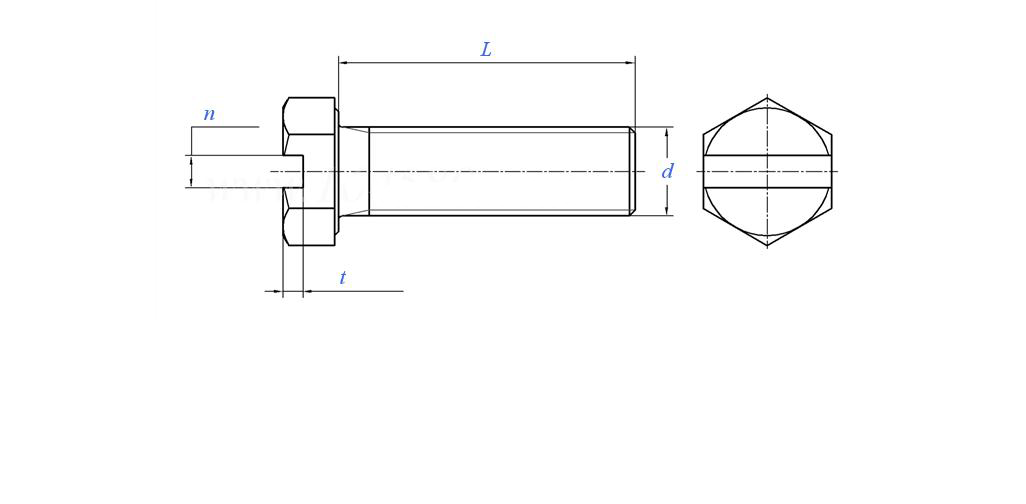

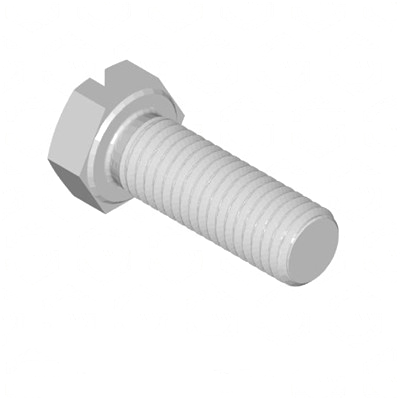

1、 Standard for hexagonal head slotted bolts

Hexagonal head slotted bolt is a commonly used fastener in mechanical connectors, with excellent performance and can be applied to various industrial occasions. In the International Organization for Standardization (ISO), the standards for hexagonal head slotted bolts are ISO 4014 (metric) and ISO 4016 (imperial).

2、 Characteristics of hexagonal head slotted bolts

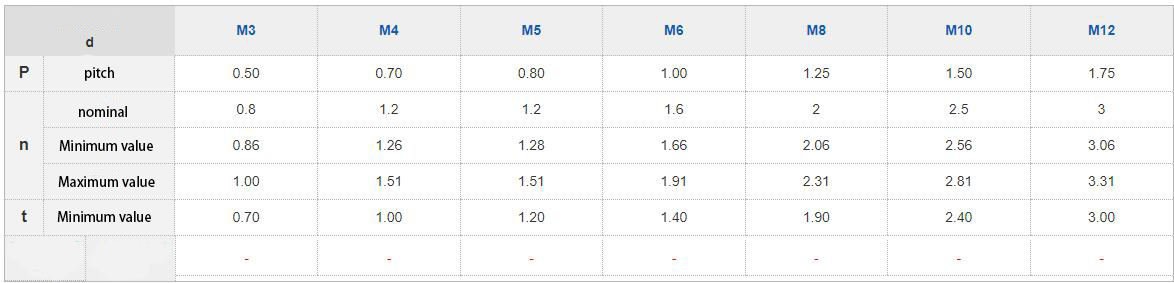

The hexagonal head with groove bolt has a hexagonal shape, which plays a role in anti slip and can also be better used with tools to achieve tightening and loosening. Its material is usually carbon steel, alloy steel, or stainless steel, which has high strength and hardness.

In fasteners, hexagonal head bolts with grooves can be installed using a flat headed screwdriver due to the design of the head with grooves, which can prevent bolt sliding and improve work efficiency.

3、 Application of hexagonal head slotted bolts

Hexagonal head slotted bolts are usually used for fastening important equipment and structural components, such as machinery, electrical appliances, automobiles, construction, and other fields. Their characteristic is that they can maintain stability in strong vibration and high temperature environments, ensuring the strength and safety of fasteners.

4、 How to choose a suitable hexagonal head slotted bolt

When selecting hexagonal head slotted bolts, the material, specifications, and dimensions need to be determined based on the specific application scenario. When selecting, factors such as the required strength of bolts, the importance of fasteners, the characteristics of the working environment, and processing methods need to be considered. If you are unsure how to choose, you can consult a professional.