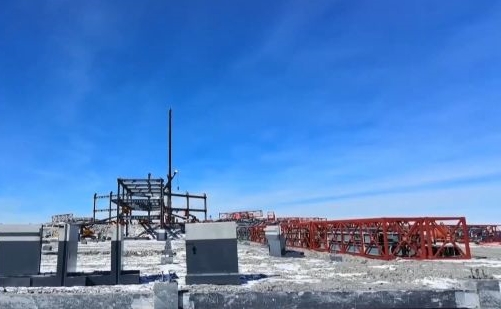

At this moment, China’s fifth scientific research station in Antarctica, the Ross Sea New Station, was completed with the main structure of the main building just a week ago on the distant island of Enkesburg in the Ross Sea.

What methods did the builders use to build the scientific research station in a short period of time?

How can the inspection station be built in just two months?

The Ross Sea currently has the largest ice shelf in Antarctica, and is the area with the most active interaction between the Southern Ocean and the Antarctic ice sheet. It is also the region with the most critical impact on global climate. It also has the largest ice free area in Antarctica – the McMurdo Dry Valley, which is of great significance for the study of the lithosphere. Various countries internationally, including the United States, Italy, Germany, South Korea, etc., have built scientific research stations here. After establishing scientific research stations here, China can expand its scientific research activities to a range of 300 to 500 kilometers through transportation such as helicopters and snowmobile vehicles, which will greatly enhance China’s scientific research capabilities and level in Antarctica.

Duan Meng, Deputy Chief Architect of China Construction Technology Group China Architectural Design and Research Institute Co., Ltd. and Chief Designer of Roshai New Station: It is not a simple building. In fact, it needs to consider its infrastructure comprehensively, such as roads, docks, energy, water treatment, and communication, all of which need to be considered as infrastructure. In addition, the functions of the building itself, such as office, scientific research, experimentation, warehouse storage, personnel living, and personnel leisure, all of these social activities should be taken into consideration. Actually, as a small research station, it is actually a miniature science city.

And this scientific research station must be built in just two months. In addition to building the main structure, it is also necessary to assemble 84 modules for internal use, which include 16 winter dormitory modules, 26 summer summer modules, as well as offices, science offices, etc.

Duan Meng, Deputy Chief Architect of China Construction Technology Group China Architectural Design and Research Institute Co., Ltd. and Chief Designer of Roshai New Station: These modules actually account for 45% of the entire construction assembly rate. This can completely complete the assembly of its modules and internal decoration in China. After arriving at the site, it can be quickly installed on the framework of our structure, and then further connected to our pipeline to move in, which is very fast.

What are the differences in steel structure production to cope with the harsh climate in Antarctica?

First, divide the production of modules and then assemble them together. This is how China quickly built the new Ross Sea station. The climate and environment in Antarctica are harsh, and the location of the Ross Sea new station is particularly prone to strong winds and weather. The main building of the new station is mainly made of steel structure. How can we ensure its durability?

The area where the Ross Sea new station is located in Antarctica has temperatures below minus 40 ℃. When the temperature is below minus 35 ℃, the steel will exhibit “cold brittleness”, reduce toughness, and be prone to fracture. This enterprise located in Xuzhou, Jiangsu Province, has been searching for this special material that is resistant to extreme cold.

Chen Rui, Chief Engineer of the Chief Engineer Office of a steel structure enterprise in Jiangsu Province: The longest column in the Antarctic project reaches 16.5 meters, which may be twice as long as this column. The conventional standard is generally within 12 meters. The difficulty of transportation has also increased, and the processing requirements for us are also higher.

It is reported that this fully assembled steel structure has a total of 4134 components, 49989 parts, a total of 71572 sets of bolts, and a total of 220000 openings.

To ensure a successful installation at the construction site, pre assembly was specifically carried out in Xuzhou before shipment, including all links from assembly to packaging and transportation, ensuring that building a house like building blocks can also be achieved in Antarctica.

What is the special design for over 70000 sets of bolts?

Due to the lack of on-site welding conditions in Antarctica, the steel structure of the Ross Sea new station was constructed through more than 70000 sets of high-strength bolts, all of which were domestically produced. What are the special designs of these bolts to withstand extreme weather in Antarctica? How was it manufactured again?

Yang Zhaojun, General Manager of a fastener enterprise in Anhui: On the surface, it appears to be steel reinforcement, but in reality, it is a special type of steel, which is a special weather resistant steel. Compared to ordinary steel, this type of steel contains more than ten special elements such as niobium, in order to improve its performance in various aspects such as ultra-low temperature impact.

After being processed by the front end of the material, the round steel becomes shiny and can be processed into shape. The mainstream practice in the industry is either cold pressing, but it can cause cracks inside the steel. Either it is heated and then processed, but the bolts used in this way cannot adapt to the extreme climate of Antarctica.

A formed bolt needs to undergo heat treatment and chemical treatment to eventually turn into a black color, which can be used in weather resistant and delayed fracture high-strength bolts in Antarctica. But that’s not all. In this laboratory, reliability testing of the bolts is still needed. Randomly select 8 out of every 3000 sets of bolts for impact performance testing in simulated extremely cold environments.

The bolts of ordinary steel structures may break at -60 ℃ with an impact force of six or seven joules, but the screws we supply to the Ross Sea in Antarctica can reach an impact force range of over 67 to 70 joules at -60 ℃.

What are the challenges facing the construction of an apron on Enkesburg Island?

In Antarctica, whether transporting goods or passengers, helicopters are indispensable. Therefore, the apron is also an essential infrastructure for every scientific research station. A new apron covering an area of 1020 square meters will also be built at the Ross Sea station in our country. The more than 400 special building materials used for parking aprons are all developed and manufactured by China itself. What are the challenges facing the construction of the apron?

He Liang, the leader of the Antarctic Apron Research Group of China Construction Technology Group East China Co., Ltd.: In the low oxygen content, low temperature, and high wind speed environment in Antarctica, if traditional construction methods are adopted, the construction period and product quality cannot be guaranteed. But we start from the source, using high-strength concrete that can be repeatedly freeze-thawed more than 200 times, and applying prestressing technology to the production and manufacturing of our product.

It is difficult to carry out construction in Antarctica, and there are many difficulties that need to be faced, among which the harsh natural environment and complex geological conditions are the key factors that cannot be avoided. Compared to traditional construction models, the characteristics of fast construction, less turnover materials, and high mechanization of prefabricated apron can better adapt to the requirements of the construction of the Ross Sea new station.

He Liang: In just 10 days of production, more than 400 pre-stressed standardized assembly type road panels were stocked.

After more than two months of drifting across the sea, these over 400 road panels have been successfully transported to Antarctica through container assembly. After the assembly of the apron is completed, ships entering the Antarctic continent can transport relevant supplies and scientific research equipment to the island, depart from the apron, and send them to various scientific research

Post time: Jan-23-2024