Tolerance and detection of thread bonding

The purpose of this chapter is to understand the characteristics of common thread interchangeability and the application of tolerance standards. The learning requirement is to understand the influence of the main geometric errors of common thread on the interchangeability; Establish the concept of thread action diameter; By analyzing the distribution of thread tolerance zone, master the characteristics of common thread tolerance and fit and the selection of thread accuracy; Understand the factors that affect the displacement accuracy of machine screw.

Type of thread and use requirements

1, ordinary thread

Usually called fastening thread, it is mainly used for connecting and fastening various mechanical parts. The requirements for the use of this type of threaded connection are screwability (easy assembly and disassembly) and reliability of the connection.

2. Drive thread

This type of thread is usually used to transmit motion or power. The use of threaded connections requires the reliability of the transmitted power or the accuracy of the transmitted displacement.

3. Tight thread

This type of thread is used for sealing joints. The use of thread requirements are tight, no water leakage, no air leakage and no oil leakage.

5. Thread measurement

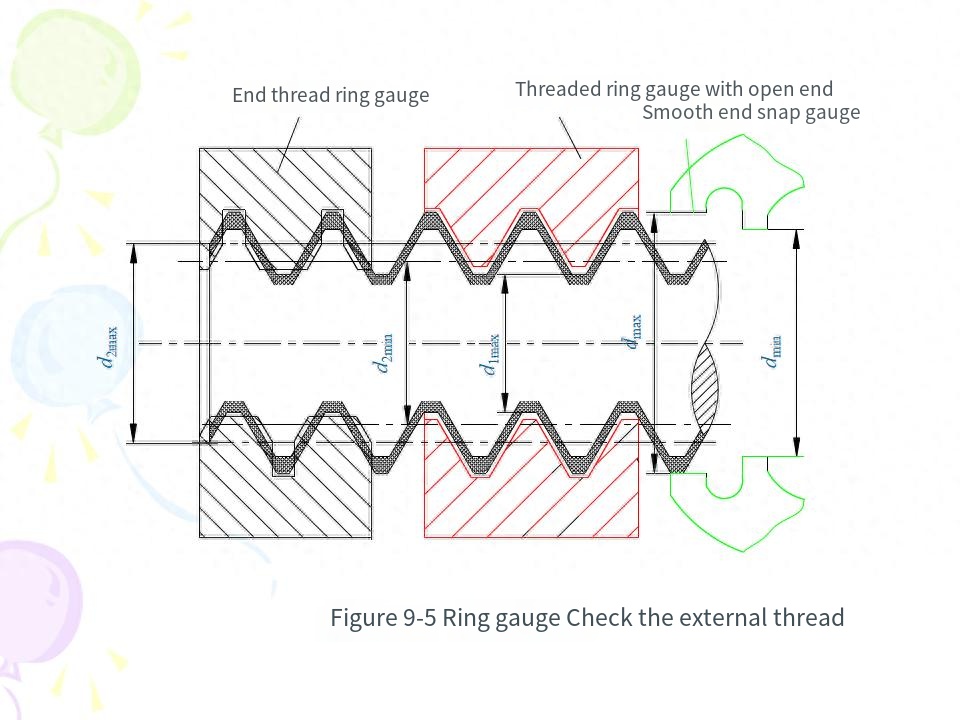

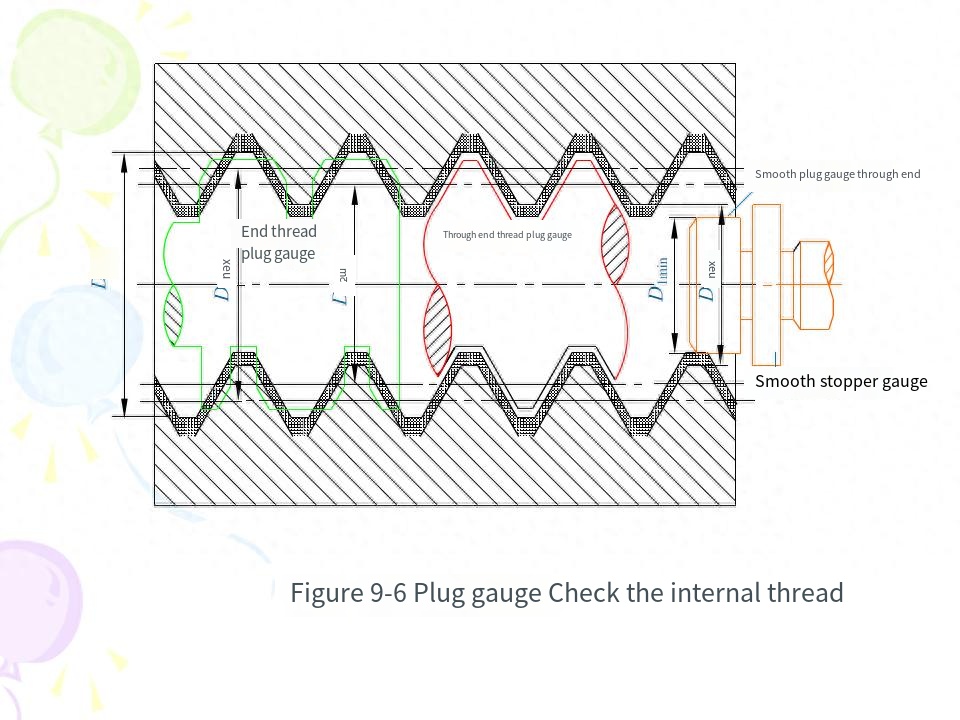

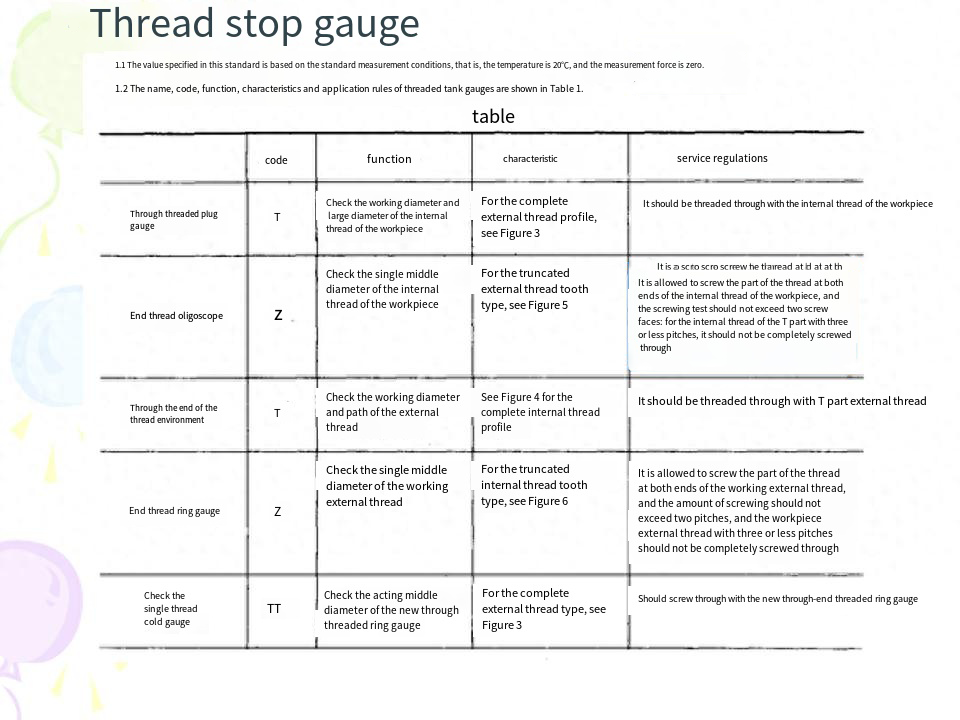

1. Comprehensive measurement

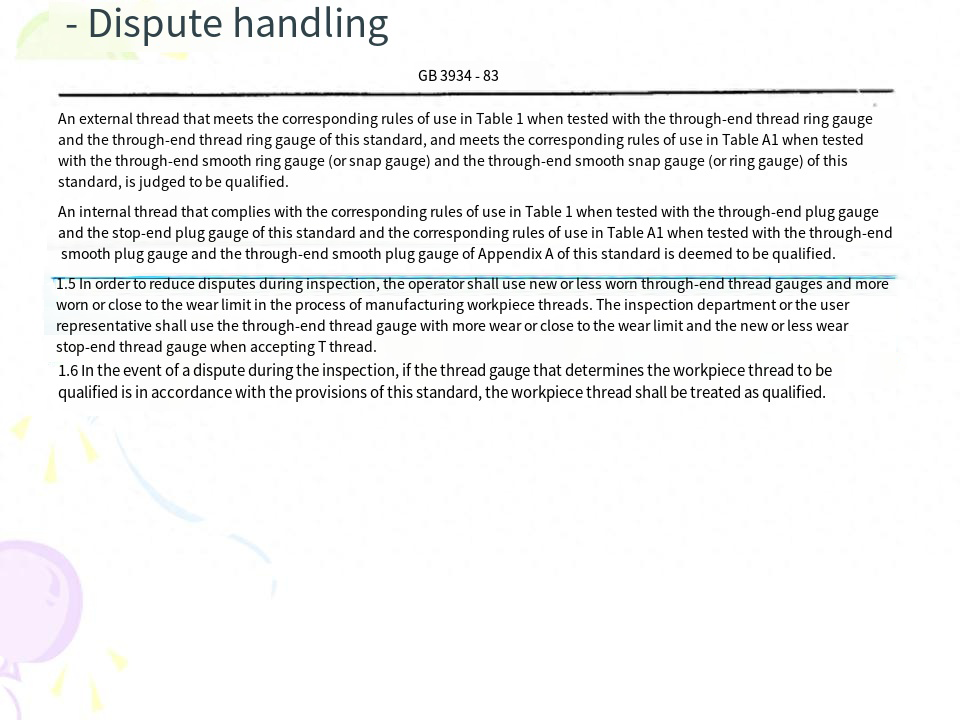

Checking thread with thread gauge is a comprehensive measurement. In the batch production, the general thread is used comprehensive measurement method.The comprehensive measurement is carried out using the thread gauge (the comprehensive limit gauge) according to the criteria for the diameter qualification of the thread introduced earlier (the Taylor principle).The thread gauge is divided into “pass gauge” and “stop gauge”. When testing, the “pass gauge” can successfully screw with the workpiece, and the “stop gauge” can not screw or incomplete screw, then the thread is qualified. On the contrary, the “pass gauge” can not be rotated, indicating that the nut is too small, the bolt is too large, and the thread should be repaired. When the “stop gauge” can pass through the workpiece, it means that the nut is too large, the bolt is too small, and the thread is a waste product.

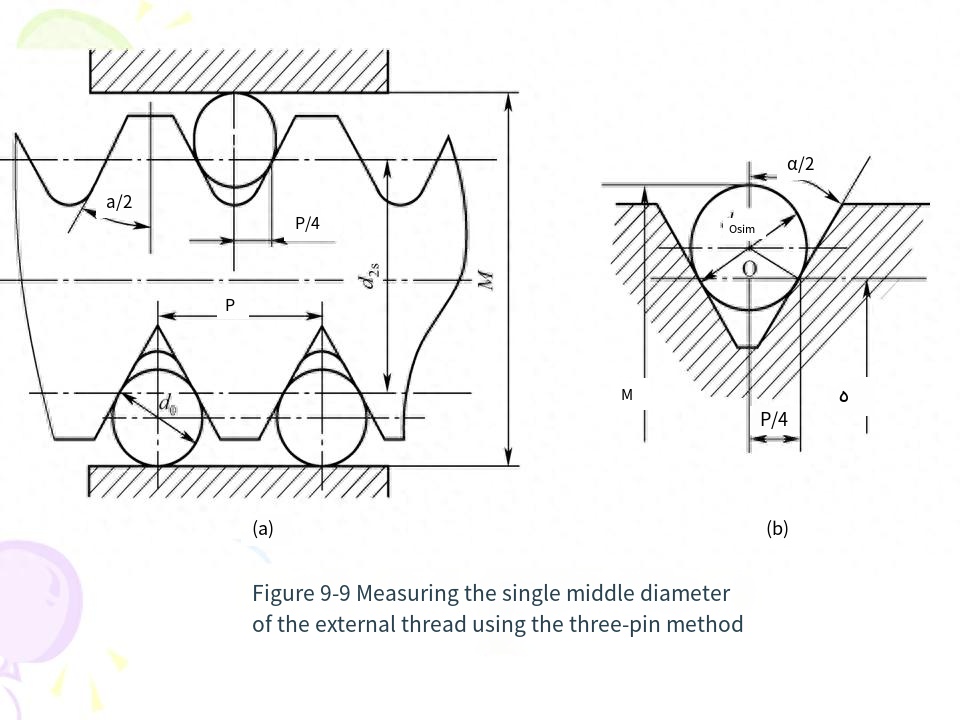

2. Single detection

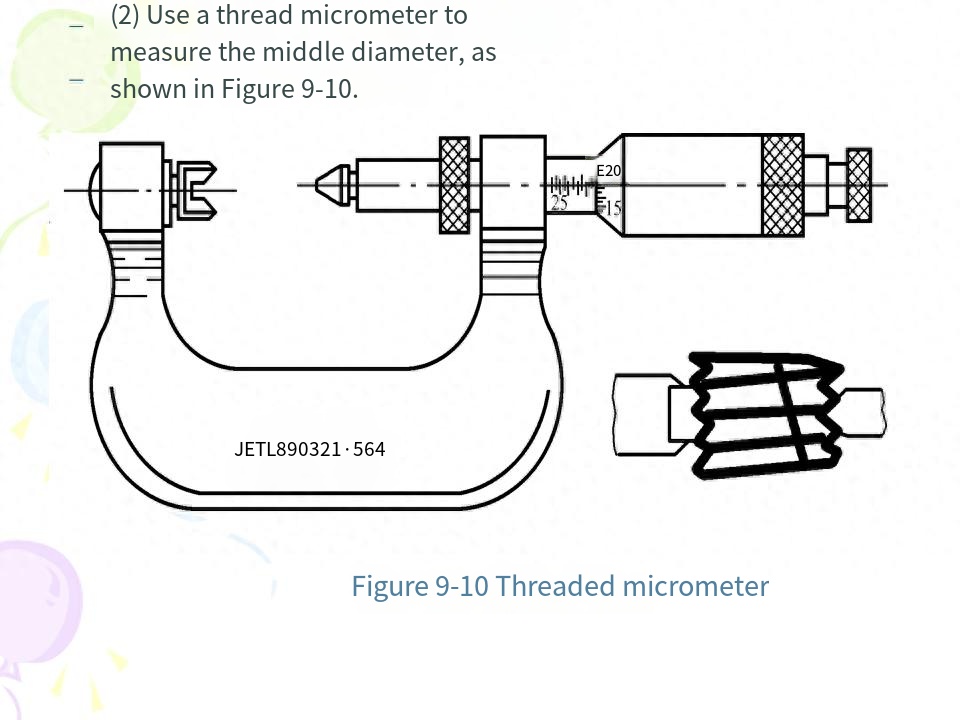

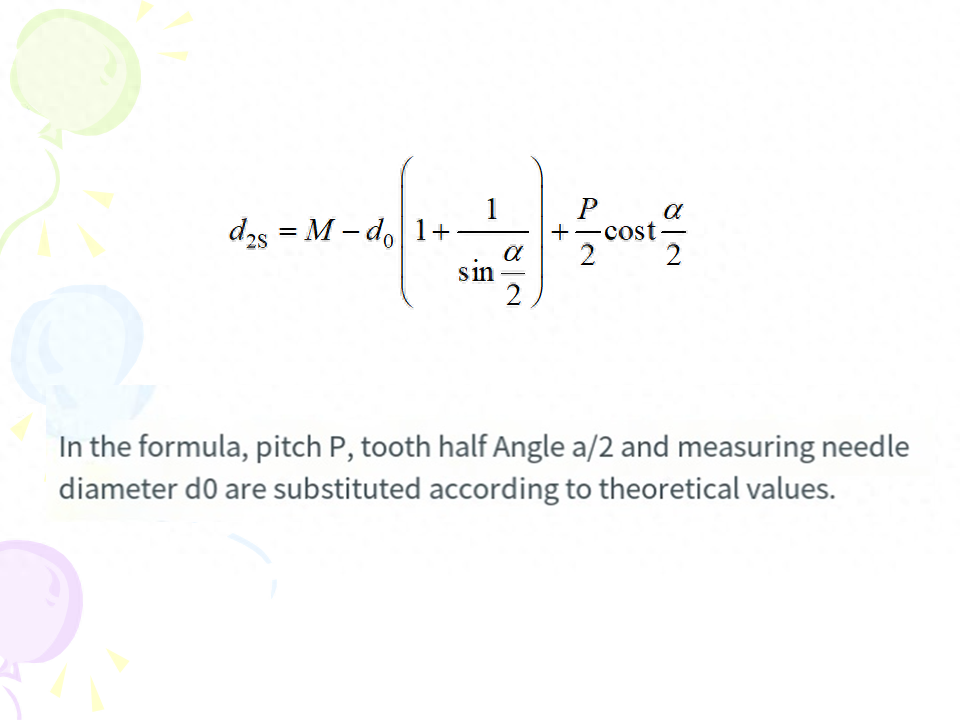

(1) Measuring the diameter of the thread with the three-pin methodThe three-pin method is mainly used to measure the single middle diameter of precision external threads (such as thread plug gauges, lead screw threads, etc.). During measurement, place three precision measuring needles of the same diameter in the grooves of the measured thread respectively, and use an optical or mechanical measuring instrument to measure the needle distance M, as shown in Figure 9-9 (a). According to the known pitch P of the measured thread and the half Angle a/2 of the tooth type, the single middle diameter d2s of the measured thread is calculated by pressing the formula.

2. Single measurement

For large size ordinary threads, precision threads and drive threads, in addition to the rotability and reliability of the connection, there are other accuracy and functional requirements, and a single measurement is generally used in production.

There are many methods for single measurement of thread, the most typical one is to use the universal tool microscope to measure the diameter, pitch and half Angle of thread. The tool microscope is used to enlarge the profile of the measured thread and measure its pitch, half Angle and middle diameter according to the image of the measured thread, so the method is also called image method.

In actual production, the three-pin measuring method is used to measure the middle diameter of external thread. This method is simple, high measuring precision and widely used

Brief summary

1. Common thread

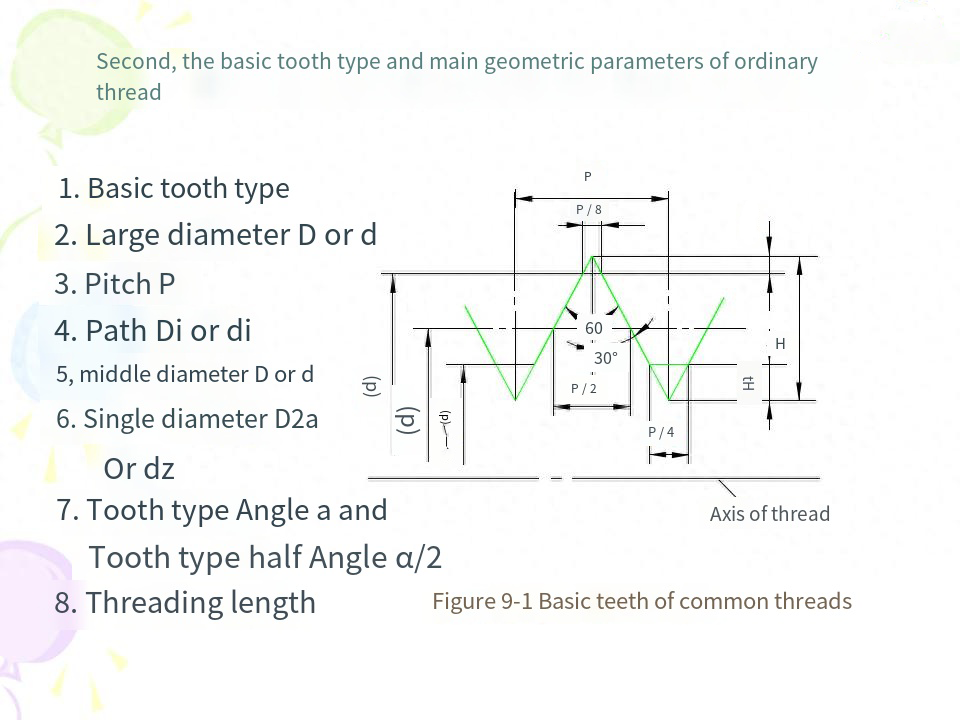

(1) The main terms and geometric parameters of ordinary threads are: basic tooth type, large diameter (D, d), small diameter (D1, d1), middle diameter (D2, d2), active middle diameter, single middle diameter (D2a, d2a) actual middle diameter, pitch (P), tooth type Angle (a) and tooth type half Angle (a/2), and screw length.

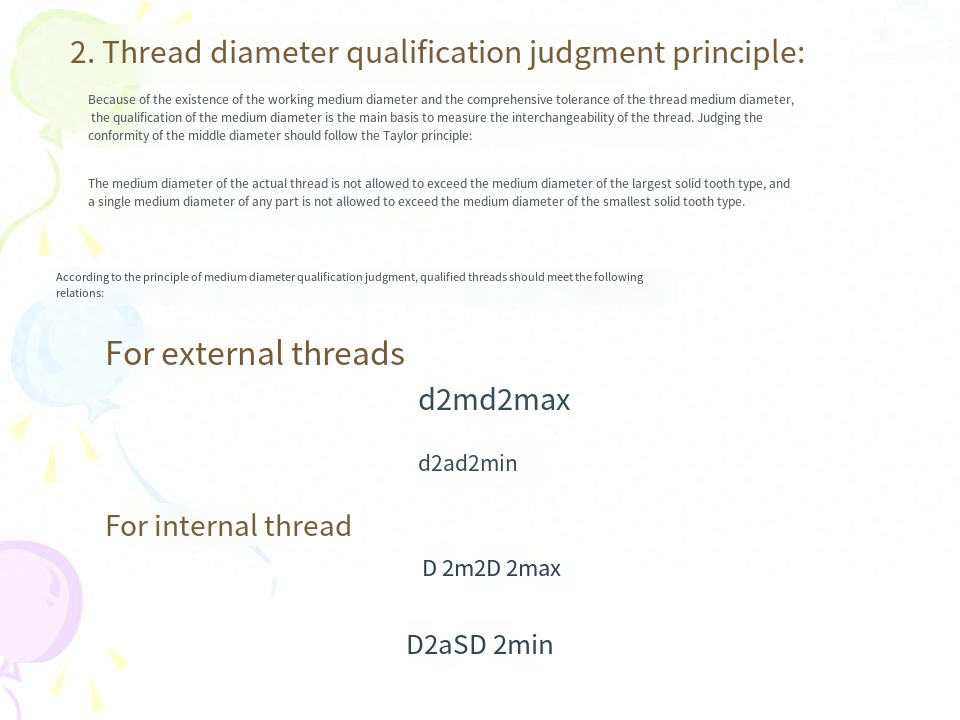

(2) The concept of the medium diameter of the action and the qualifying conditions of the medium diameter

The size of the active medium diameter affects the spinability, and the size of the actual medium diameter affects the reliability of the connection. Whether the medium diameter is qualified or not should follow the Taylor principle, and both the actual medium diameter and the active medium diameter are controlled within the tolerance zone of the medium diameter.

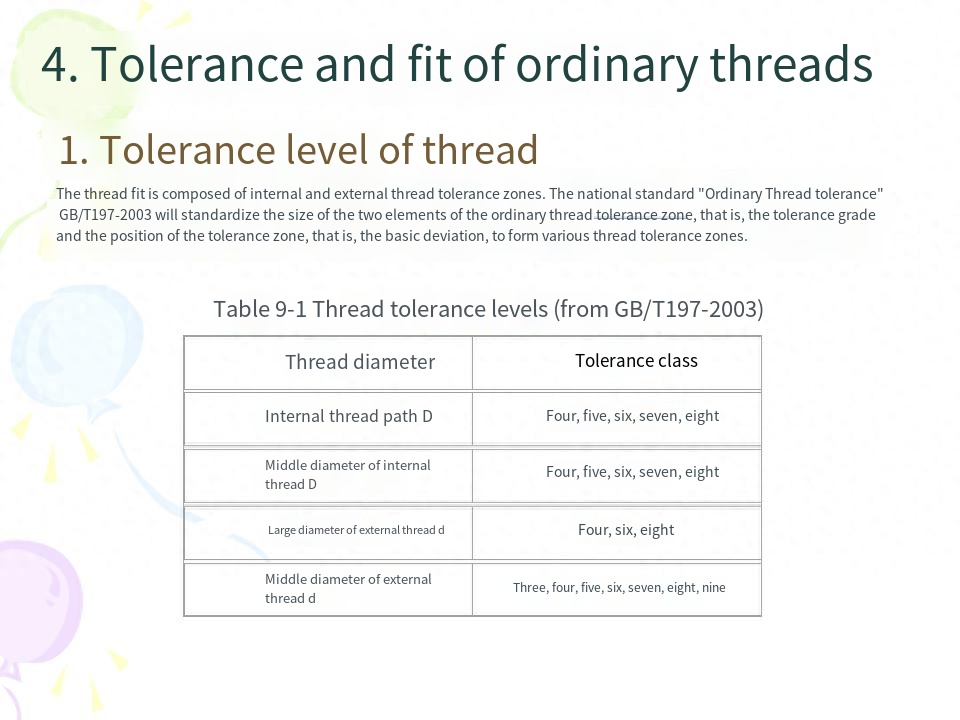

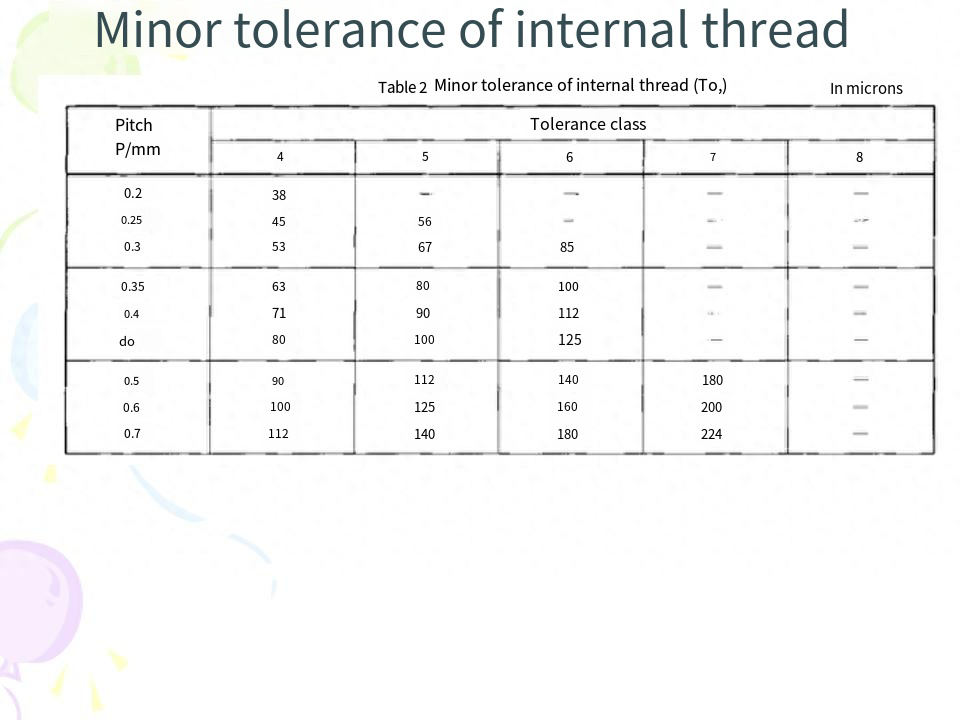

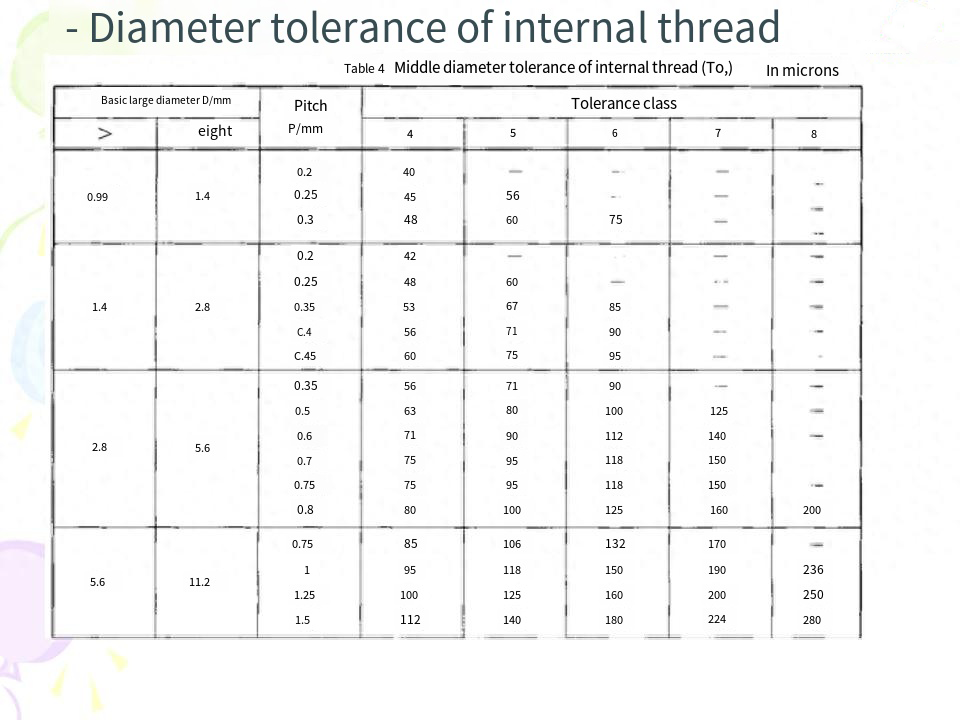

(3) Common thread tolerance level In the thread tolerance standard, the tolerances of d, d2 and D1, D2 are specified. Their respective tolerance levels are shown in Table 9-1. No tolerances are specified for pitch and tooth type (controlled by the middle diameter tolerance zone), and no tolerances are specified for small diameter d of external thread and large diameter D of internal thread.

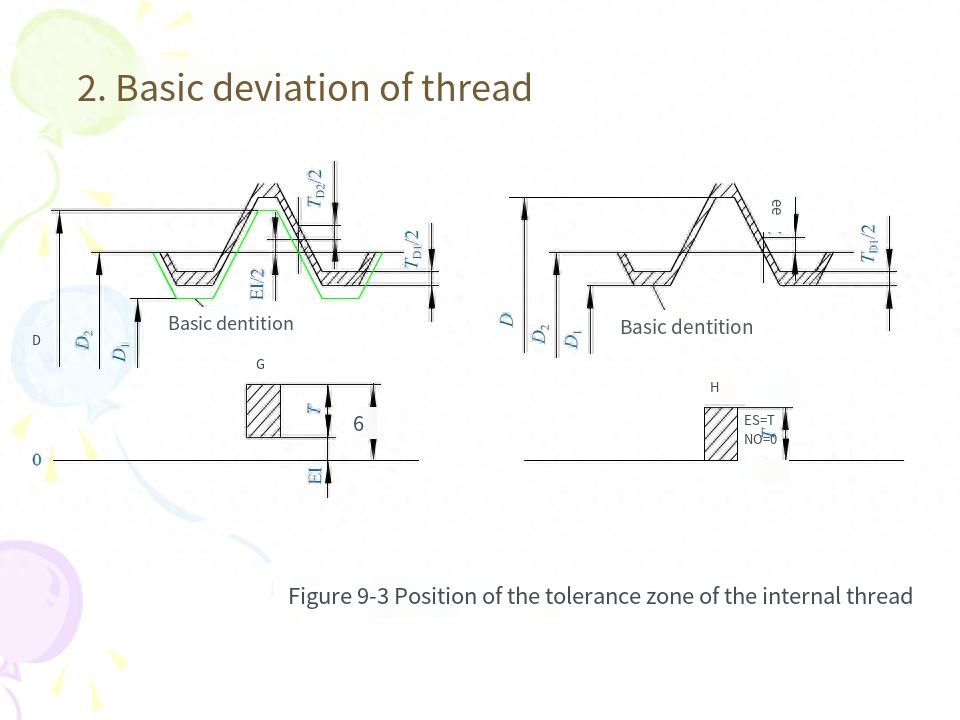

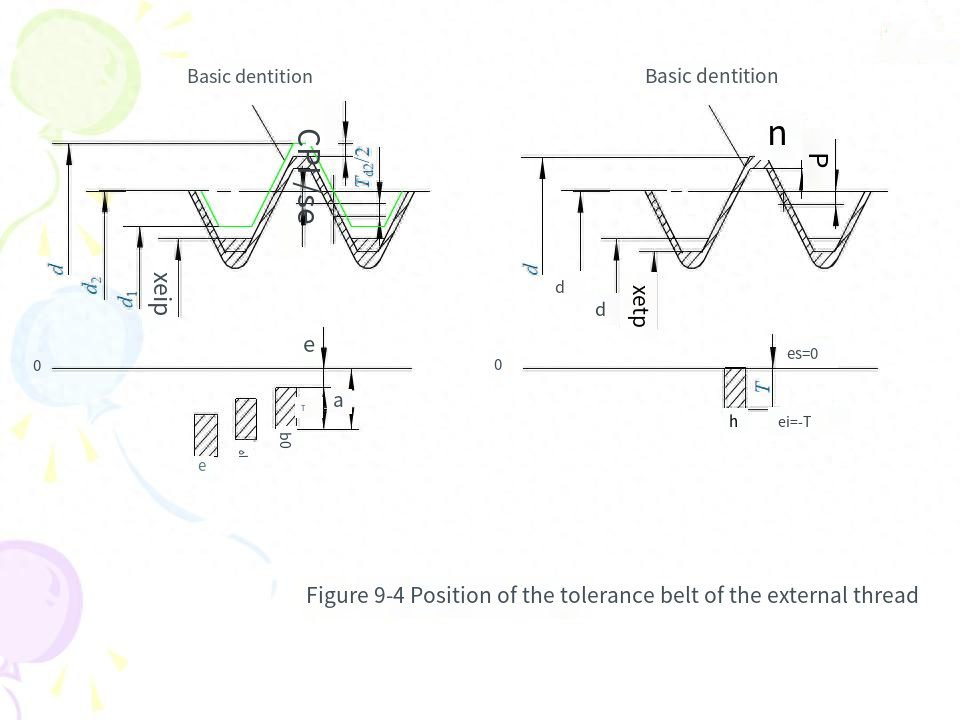

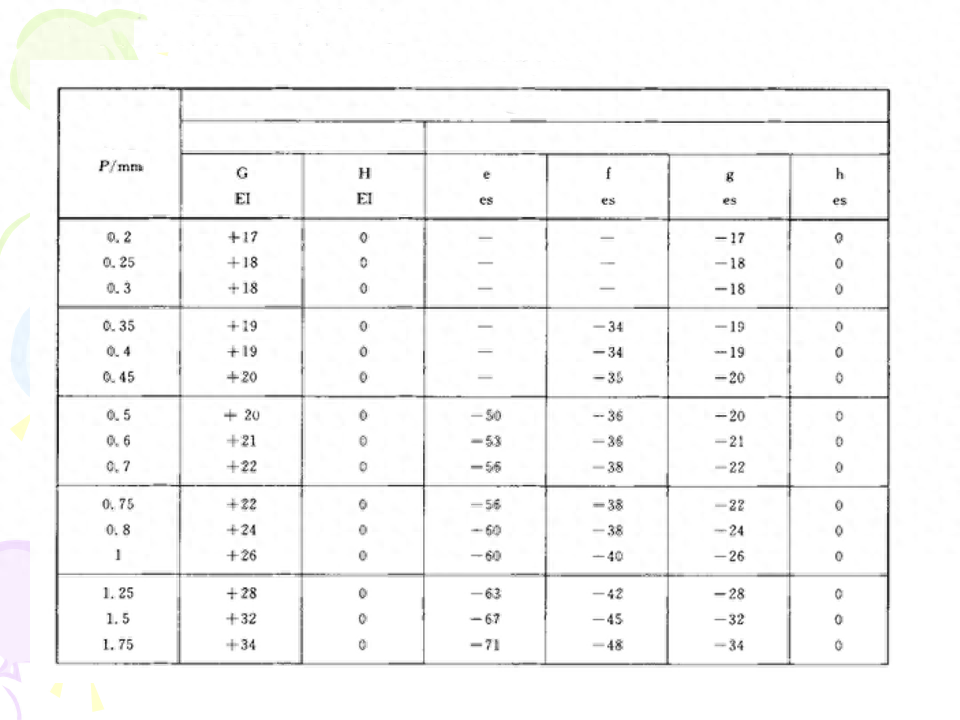

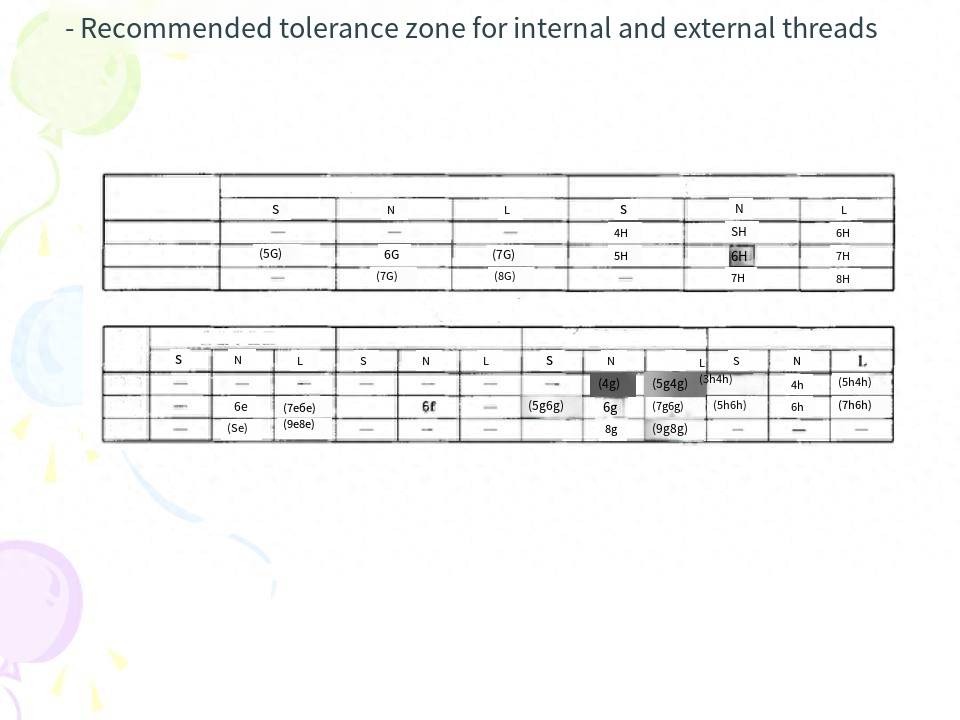

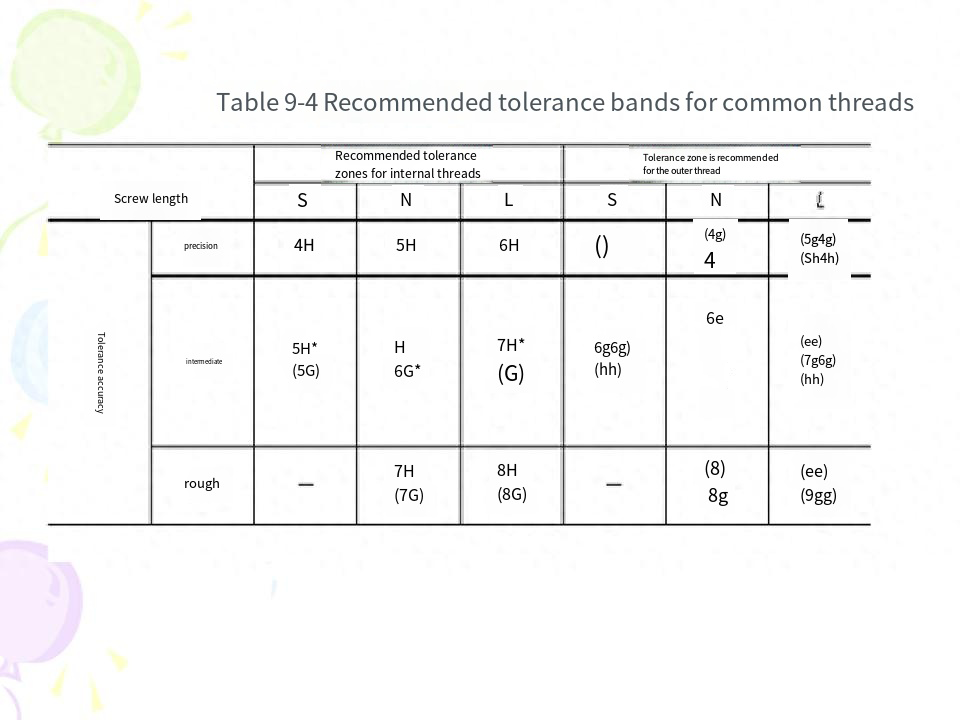

(4) Basic deviation For external threads, the basic deviation is the upper deviation (es), there are e, f, g, h four kinds; For internal threads, the basic deviation is the lower deviation (El), there are two kinds of G and H.The tolerance grade and the basic deviation constitute the thread tolerance zone. The national standard specifies the common tolerance zone, as shown in Table 9-4. In general, the preferred tolerance zone specified in the table should be selected as far as possible. The selection of tolerance zones is described in this chapter.

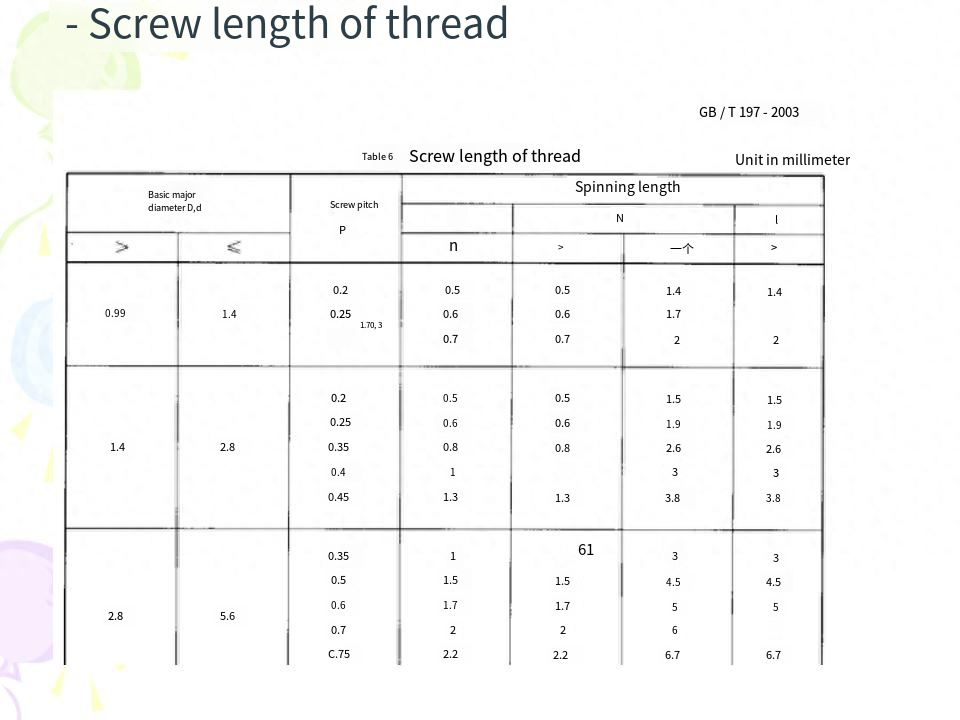

(5) Screw length and precision grade

The screw screw length is divided into three types: short, medium and long, denoted by code S, N and L, respectively. The values are shown in Table 9-5

When the tolerance level of the thread is fixed, the longer the screw length, the higher the cumulative pitch deviation and the tooth half Angle deviation may be. Therefore, the thread according to the tolerance level and the length of the screw has three precision levels: precision, medium and rough. The application of each precision level is described in this chapter. With the same accuracy level, the tolerance level of the thread should be reduced with the increase of the spinning length (see Table 9-4).

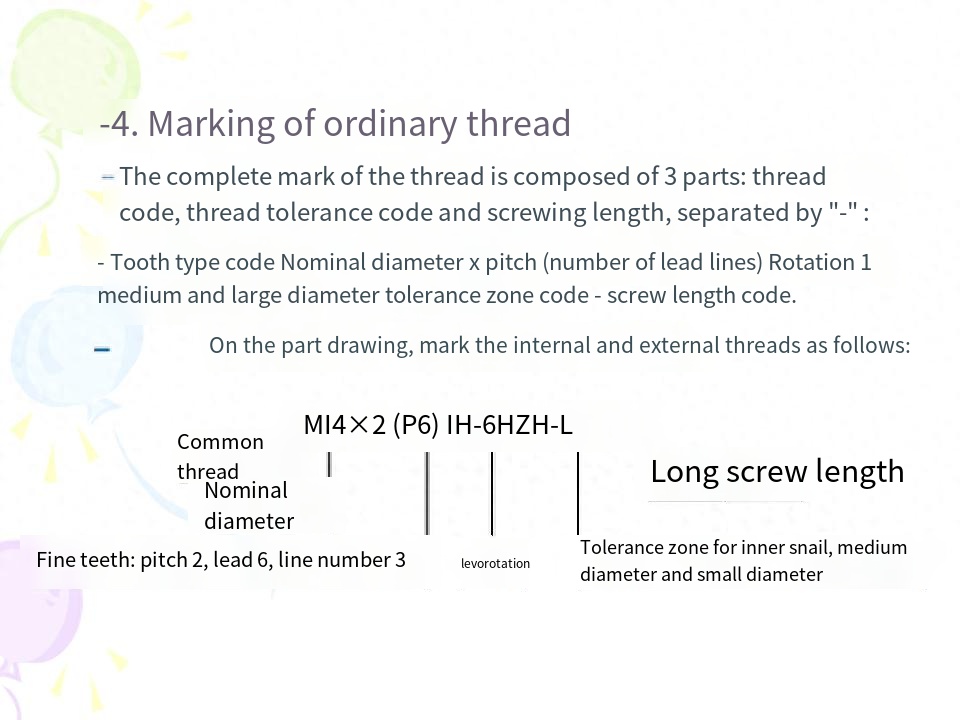

(6) The marking of threads on the drawing is shown in the relevant contents of this chapter.

(7) The detection of threads is divided into comprehensive detection and single detection.

Post time: Sep-20-2023