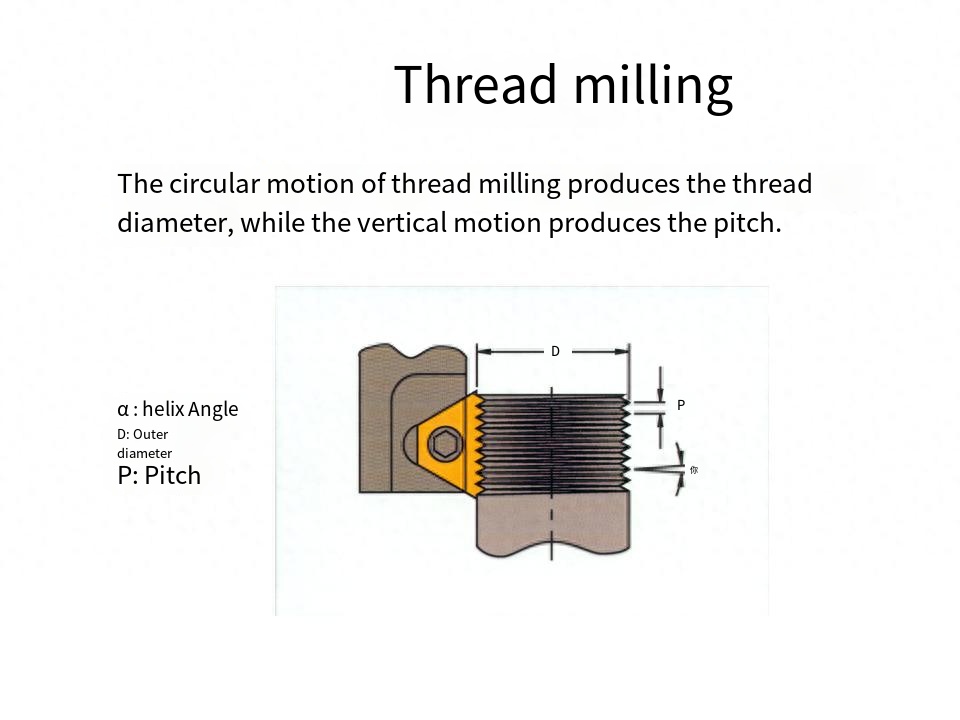

The research work on thread milling mainly focuses on both theoretical and technological aspects. Thread milling generally involves multiple cutting operations, including rough machining and precision machining. However, for difficult to machine materials, the cutting force during milling is significant, which has a significant impact on machining accuracy and tool life. Generally, the processing strategies used in practical engineering lack guidance for thread milling of difficult to machine materials.

The expression method of cutting thickness was analyzed for thread milling of high-temperature alloy materials, and the expression method of cross-sectional area formed by two adjacent tool passes was established. On this basis, the milling force and torque during the milling process of high-temperature alloy threads were studied. The results showed that the milling force and torque were positively correlated with the cross-sectional area during thread milling. A machining strategy was proposed to optimize the radial cutting depth of high-temperature alloy thread milling by equalizing the cross-sectional area of each cutting during the coarse and fine machining process. This strategy can effectively control the cutting force and torque values, which is not only beneficial for improving tool life and machining accuracy, but also provides a basis for formulating thread milling processes for difficult to machine materials.

Application field

Milling is the best option when threads need to be machined in the following situations:

Non-rotating or asymmetrical parts

Machining blind holes without threaded retracting slots

Large bore diameter

Intermittent cutting

Advantages of thread milling

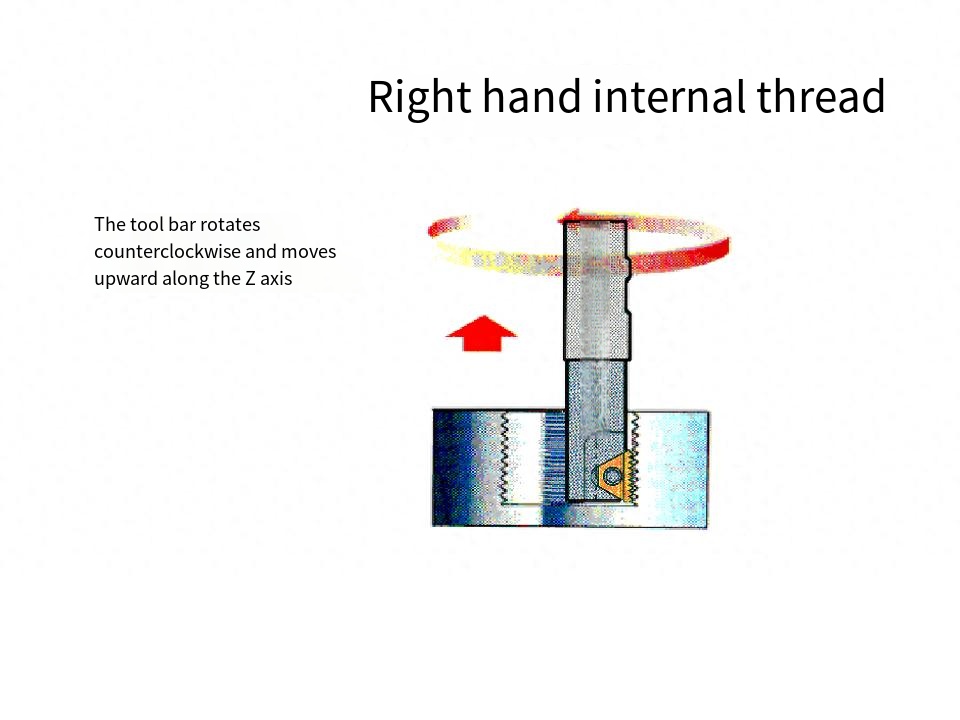

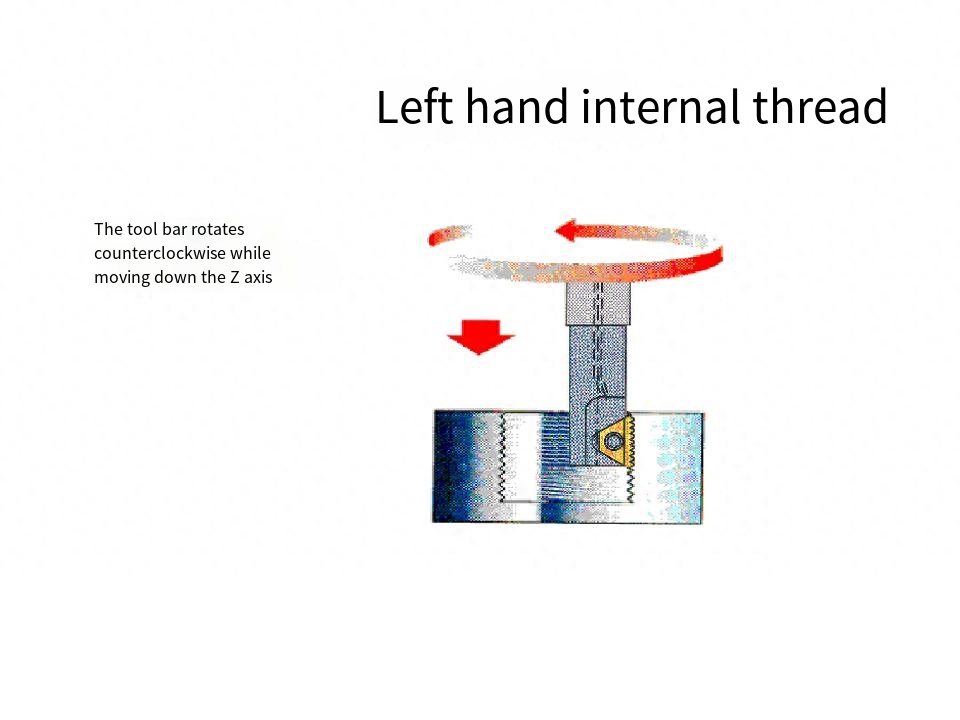

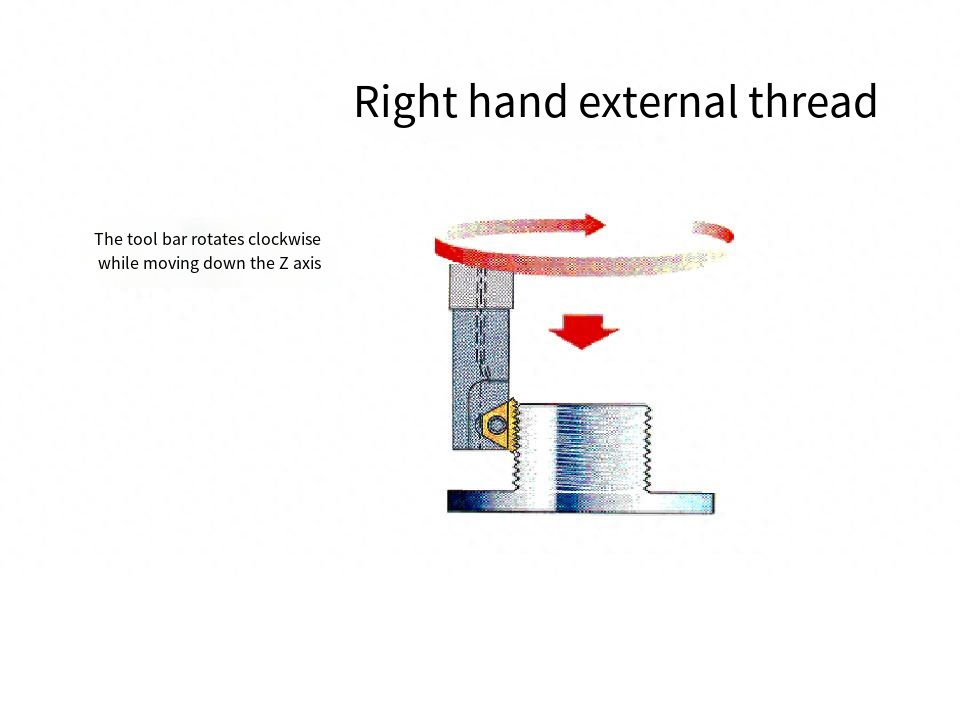

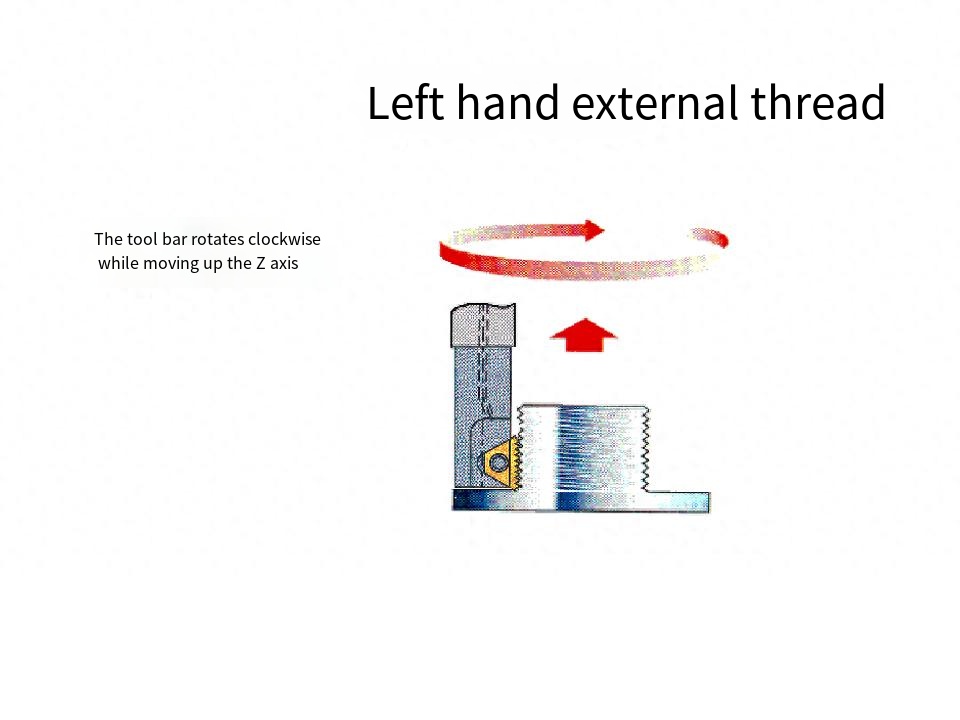

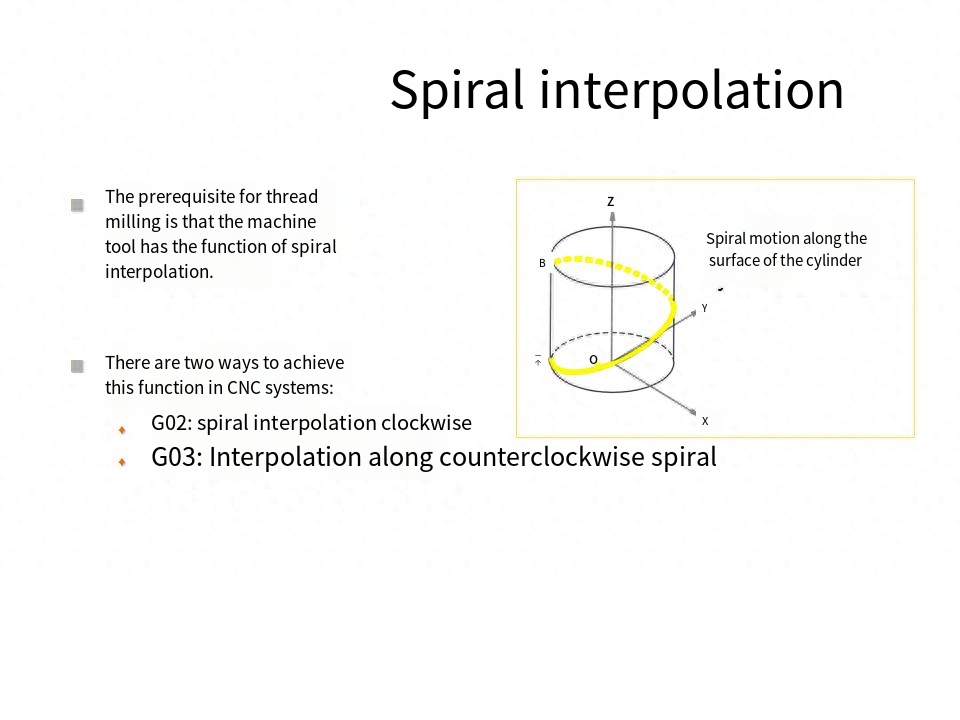

All thread milling blades are full-tooth or top-tooth types with high speed cutting and fast feed to save machiningtime when the workpiece is difficult to position and the thread size is large, which reflects the efficient performance of thread millingThe same tool can complete the machining of both left and right hand threadsThe same tool bar is suitable for machining internal and external threadsThe same tool bar is suitable for blades with different pitch specifications

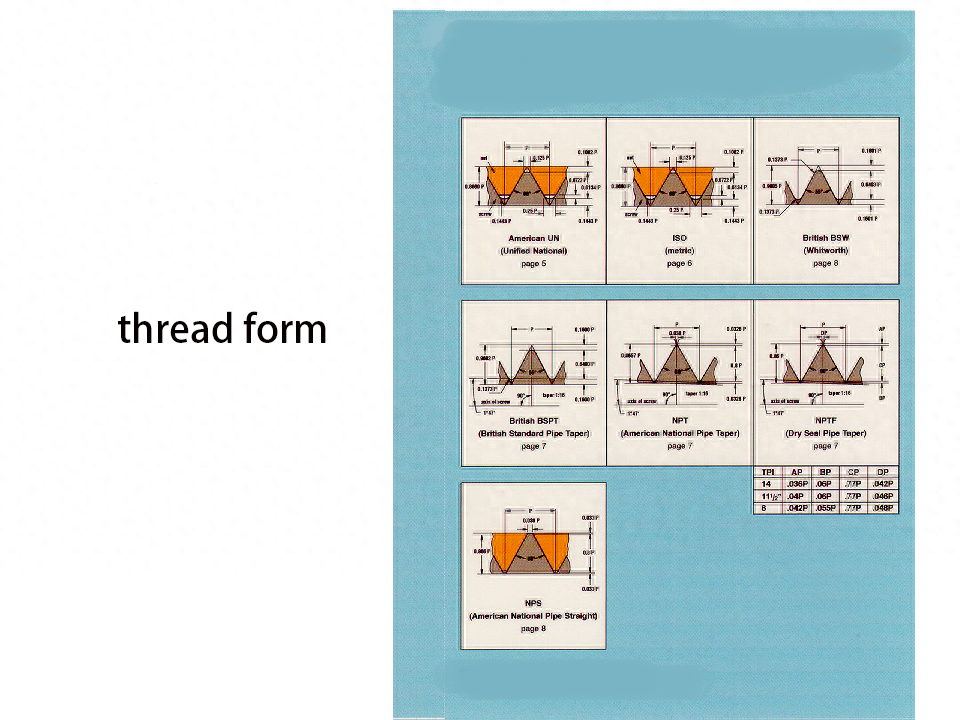

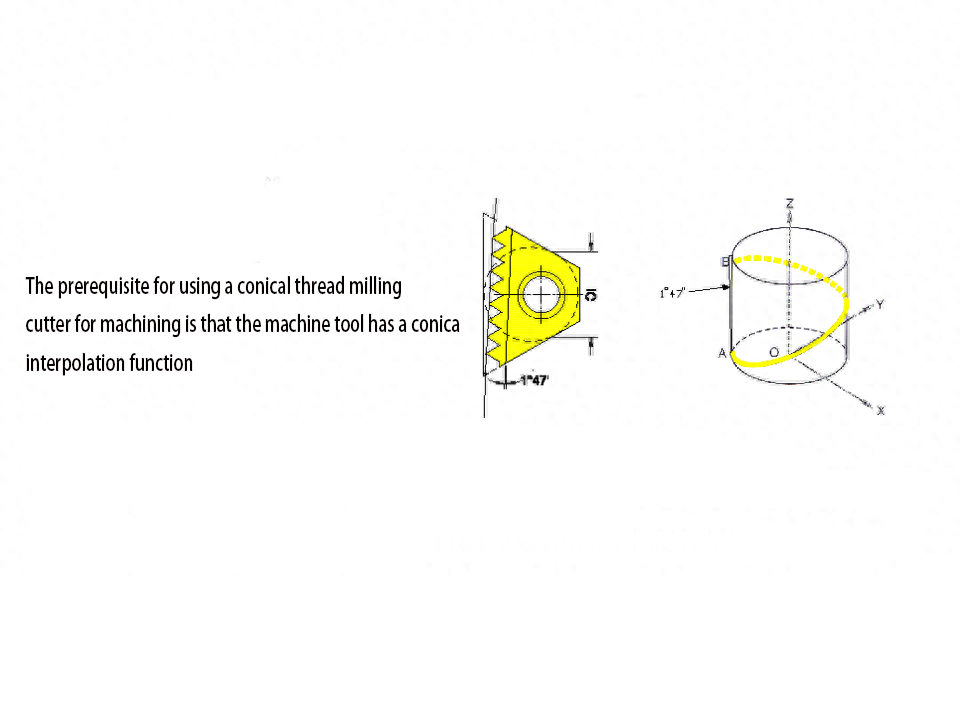

Blades with standard teeth can be interchangeableNPT thread can be processedSuitable for processing hard materialsShort chipGood surface roughness can be obtainedMilling requires less torque than machining large diameter threads with taps

The tool offset allows easy size controlThe same tool can be used to process threads with the same pitch and different diameters without expensive tapping devicesNo tapping breaks occur and need to be removed by expensive EDM devicesInch internal and external threads can be machined with the same bladeFull threads can be machined directly from blind holes

Post time: Oct-19-2023