5, bolt removal common problems

When loosening the flange bolts of pipes and valves:

Should be loosened away from the body half of the bolt, so that the remaining oil, steam, water from the opposite discharge, in case of spray, scalding

If the bolt has glue that cannot be unscrewed:

Most glues are organic solutions that can be soaked in banana water or alcohol for half an hour,Or cover the bolts with alcohol cotton for a longer period of time to dissolve the glue

The bolt rust can not be unscrewed:

Spray WD-40, wait half an hour, the spray will penetrate the middle of the bolt dissolve rust blocksOther methods: vibration, lubrication, fire, electric drill

When the bolt slip teeth can’t be unscrewed:

Corrosive solution can be used to slowly corrode the bolt, such as dilute sulfuric acid and hydrochloric acidAcid for metals, alkali for plastics

6. bolt use common misunderstandings

1. Substitute coarse for fine:

Some important connecting parts, such as transmission shaft, flight shaft, etc., the bolts are multi-threaded with fine teethThe fine bolt has small pitch and outer Angle, and has the advantages of high strength, good self-locking performance, and strong ability to withstand impact, vibration and exchange loadAfter the coarse teeth bolt is used instead, it is easy to loose or take off or disassemble, resulting in accidents

2. pore mismatch:

Bolts that bear lateral load and shear force (such as drive shaft bolts, flywheel bolts), they are matched with bolt holes for transition, and the assembly should be solid and reliable, and can withstand side forcesIf you do not pay attention to check in the assembly, the bolt is still installed when there is a large gap between the bolt and the bolt hole, the result may be loose or cut off the bolt accident

3. Thickened nut:False point: Thickened nuts can increase the number of working turns of the thread, thereby improving the reliability of the couplingIn fact, the thicker the nut, the more uneven the load distribution between the threads of each ring, the easier it is to lead to loosening of the connector

4. One female multi-pad:

(>2)Sometimes the bolt after assembly is too long, so some people put many spring washers on a boltDuring the fastening process, the force of the spring washer is uneven, and some will break, so that the pre-tightening force of the bolt will decreaseOr produce eccentric load, reduce the reliability of the bolt connection

5. The washer is too large:

(GB/T 97.1-2002 M5-M36 in Table 1: the inner diameter of the washer is greater than the diameter of the thread 0.3mm~1mm)Wrong approach: Due to lack of suitable gaskets, use a larger inner diameter gasket insteadIn this way, the contact area between the bolt head and the washer is small, the pressure or locking force of the washer is reduced, and the bolt is easy to loosen under the action of vibration and impact load

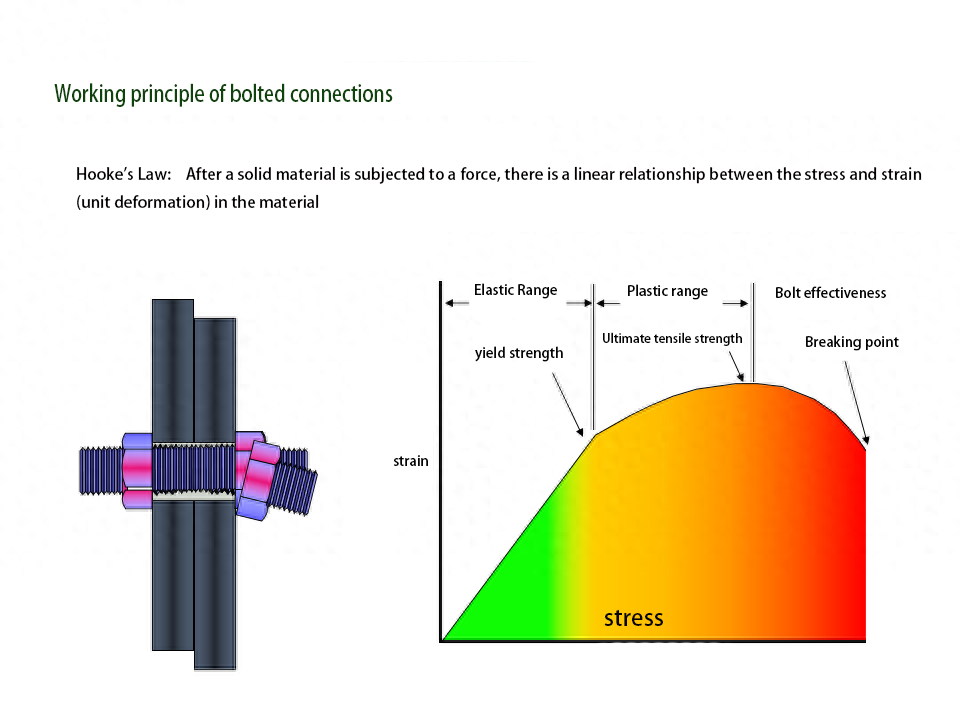

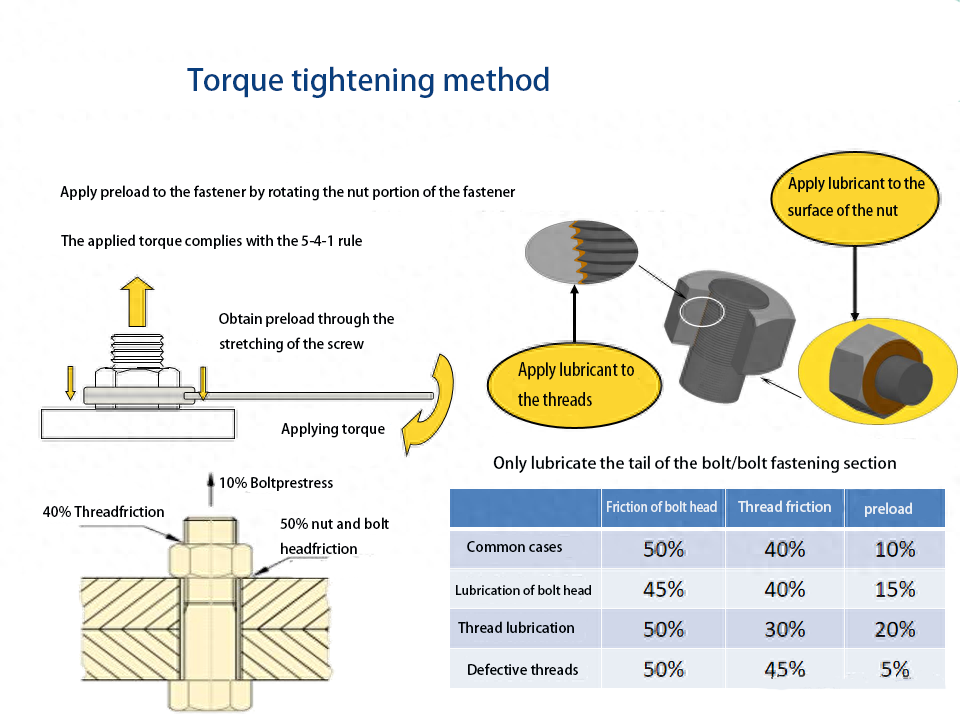

6. Torque discrepancy:

Wrong view: Think that the bolt should be “rather tight than loose”, so they consciously increase the tightening torque of the boltConsequences: cause the bolt to slip, or even screw offWrong way: For important bolts that need to be tightened with torque, and to save trouble by using an adjustable wrench to twistConsequences: loose due to insufficient torque, resulting in failure

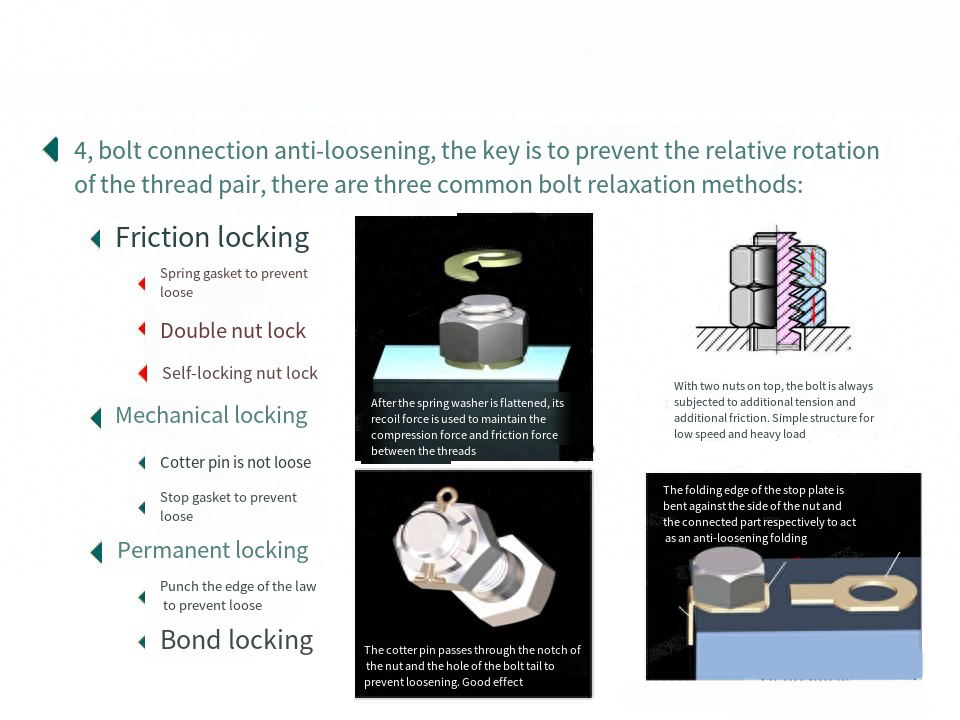

7. Improper locking:

After the assembly of important bolts, the locking device should be takenWhen using cotter pin locking, a common mistake is to lock with too thin opening lock or half piece opening lockWhen the spring washer is used for locking, the common mistake is that the spacing of the washer opening is too small and the elasticity is lostWhen the lock plate is used, the common mistake is to lock the lock plate at the corner of the nut. When the double nut is used to lock, the common mistake is to install the thinner nut on the outside and screw it not tightly

8. False firmness:

There are rust stains, scale, iron filings, sand, burrs, etc. in the threads of bolts, nuts or holes to be removed before assembly. When tightening bolts, the surface torque value meets the requirements due to the blocking effect of impurities, but in fact the connector is not really pressed

Post time: Oct-13-2023