With the rise of the new energy vehicle industry, China has become the world’s largest exporter of automobiles. According to data from the Hunan Provincial Department of Industry and Information Technology, in the first three quarters of this year, Hunan produced a total of 600000 new energy vehicles, accounting for 9.5% of the country’s total production during the same period; A year-on-year increase of 92%, 58.3 percentage points higher than the national average growth rate. Hunan automobile companies and component manufacturers continue to make efforts to accelerate the improvement of local matching rates and boost the pace of automobile exports.

In the first 10 months of this year, BYD exported over 176000 new energy vehicles and won the monthly sales champion of electric vehicles in countries such as Thailand and Singapore multiple times, an increase of 214% compared to last year. Among them, Changsha BYD exported over 9000 vehicles. In the production workshop of BYD in Changsha, this large and medium-sized high-end new energy business vehicle has won market favor with its comprehensive performance suitable for both household and public use. In just 11 months, this car has become the fastest delivery of 100000 mass-produced new energy luxury vehicles in China.

Yi Long, General Manager of BYD Co., Ltd. in Hunan Province: BYD’s new energy vehicles have been exported to 70 countries and regions worldwide, including automotive industry powerhouses such as Japan and Germany. In the future, the company will accelerate its pace of going global, launch more export models, and use leading products and technologies to help China consolidate its position as the first automobile exporting country.

As one of the seven billion level pillar industries in Changsha, automobile and component manufacturing has developed rapidly in recent years, but still faces the problem of relatively low local matching rate, with a matching rate of only 29%. Compared to cities such as Shanghai, Chongqing, and Hefei, there is still a significant gap in this proportion. In the future, Changsha will strive to increase the local supporting rate to over 50%.

The wheel hub is the core part of the wheel, carrying the weight of the entire vehicle. Currently, the monthly demand for wheel hubs by automobile manufacturing enterprises in Hunan Province is about 350000 pieces. The CITIC Daika Southern Intelligent Manufacturing Base, located in Wangcheng District, Changsha, produces 12 million wheels annually, accounting for 50% of the provincial market. Last year, the base achieved a sales revenue of 4.8 billion yuan, a year-on-year increase of nearly 40%. In order to adapt to the rapid growth in demand for automotive components, enterprises are actively transitioning from a “single component supplier” to a “modular, lightweight, and integrated component supplier”. It is expected that the supply of wheel hubs in the province can be increased to about 70% next year.

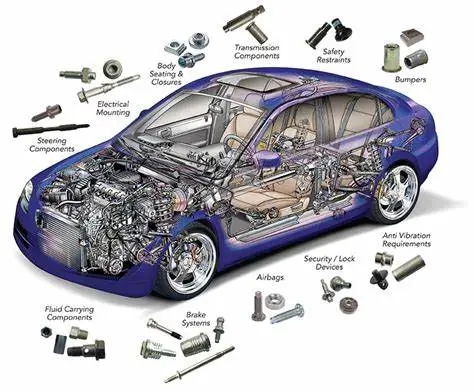

A car consists of tens of thousands of components, and the rapid development of new energy vehicles provides vast opportunities for related component production enterprises.

Post time: Dec-13-2023