1.Why do we need to perform static torque testing?

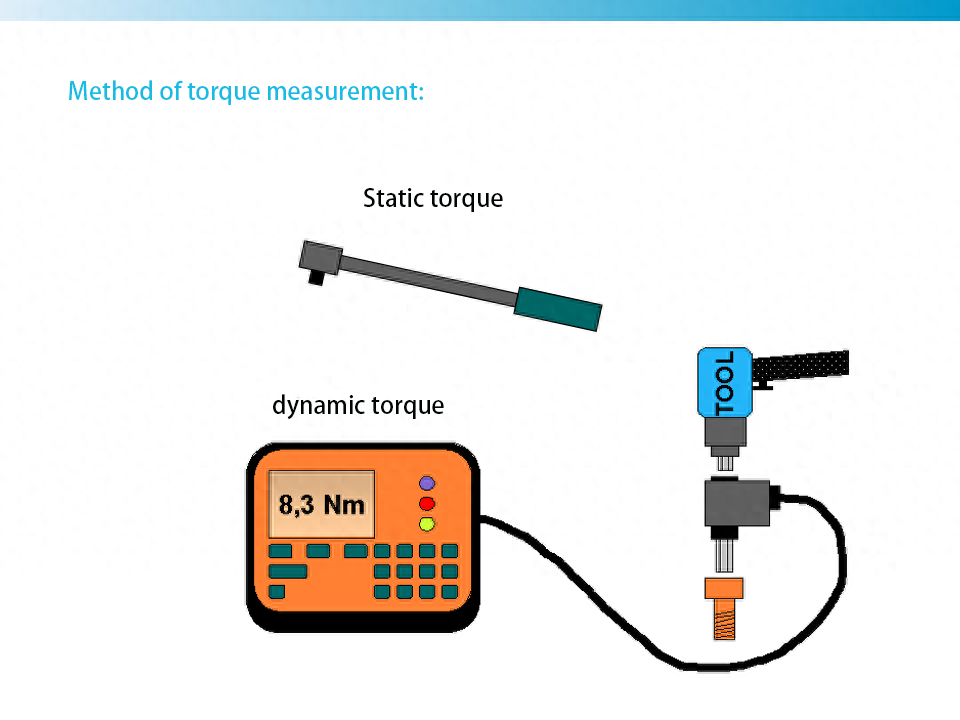

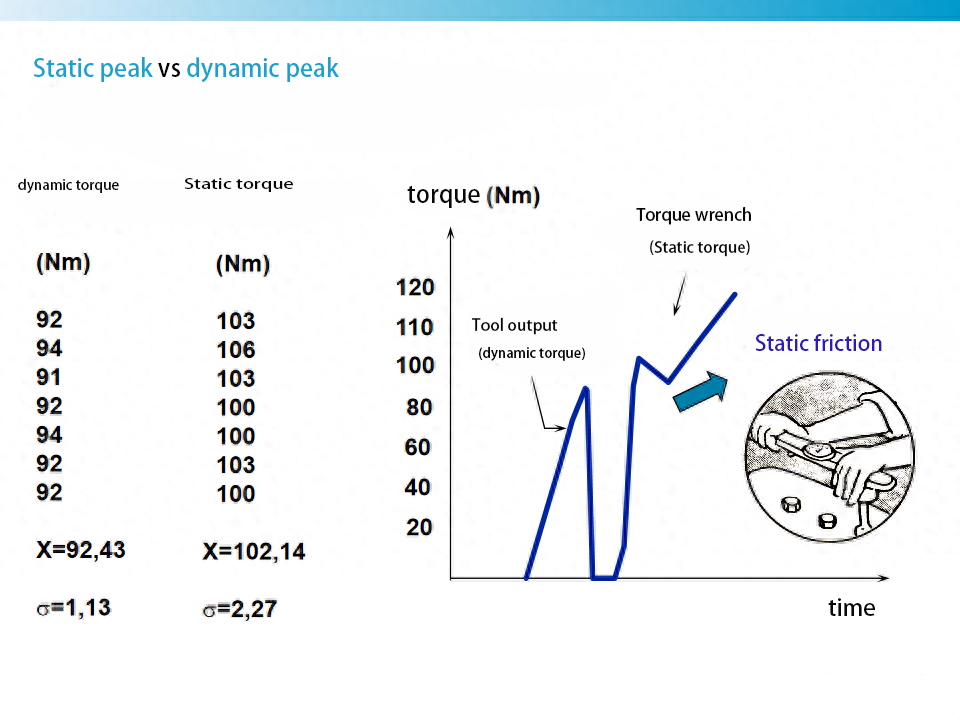

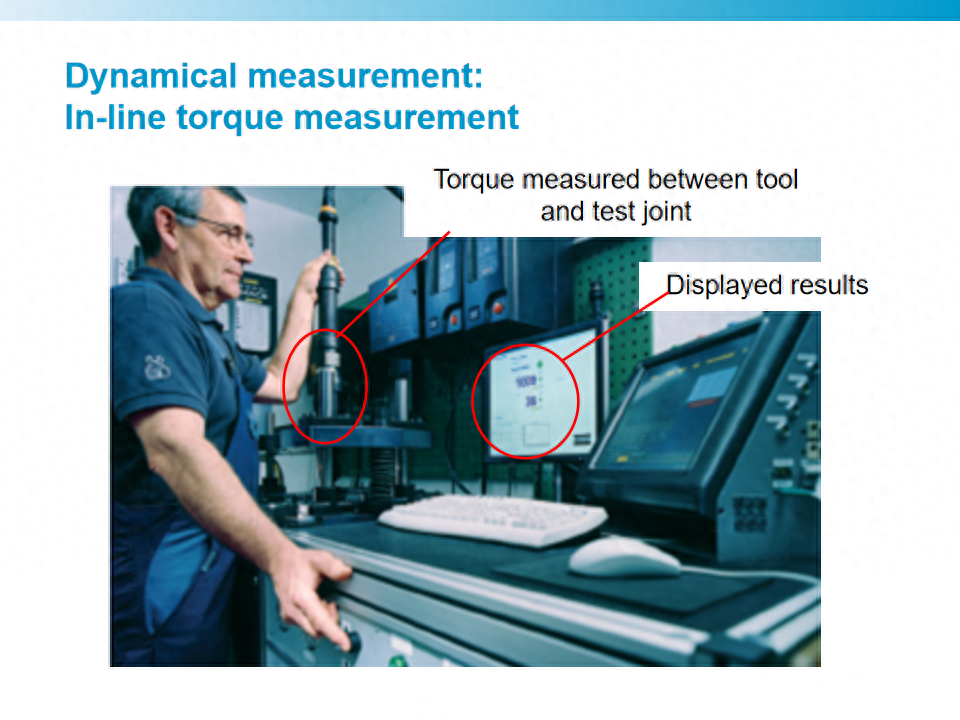

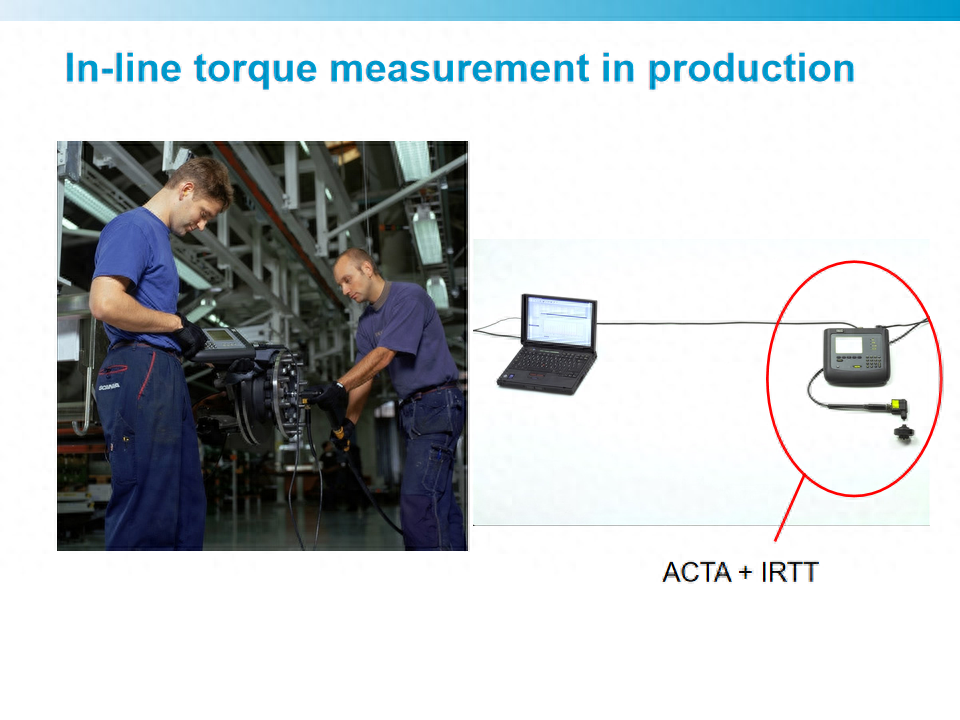

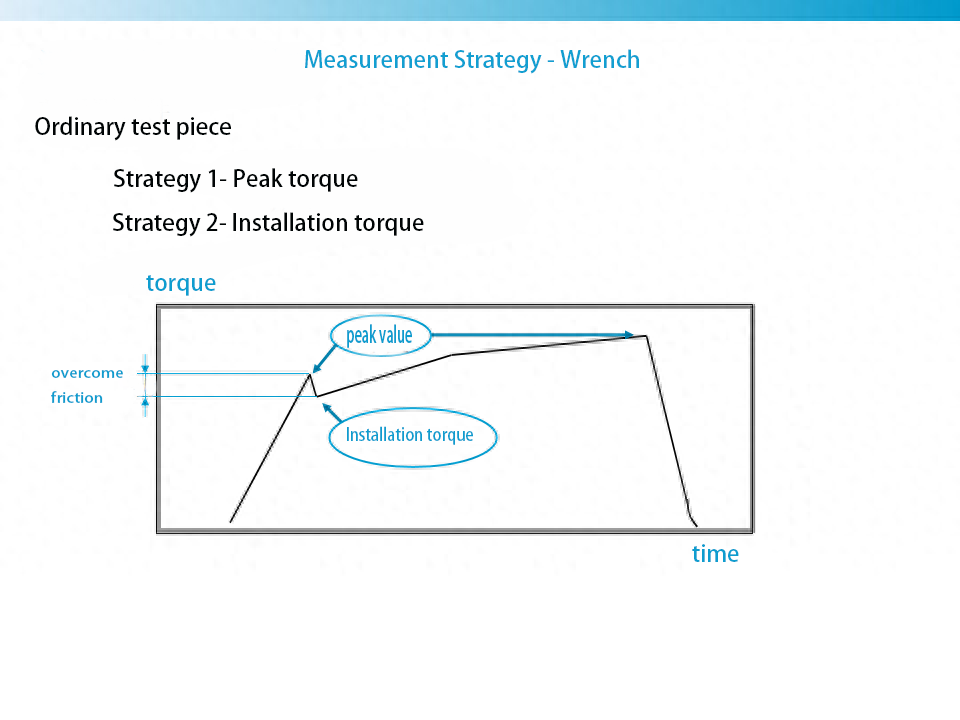

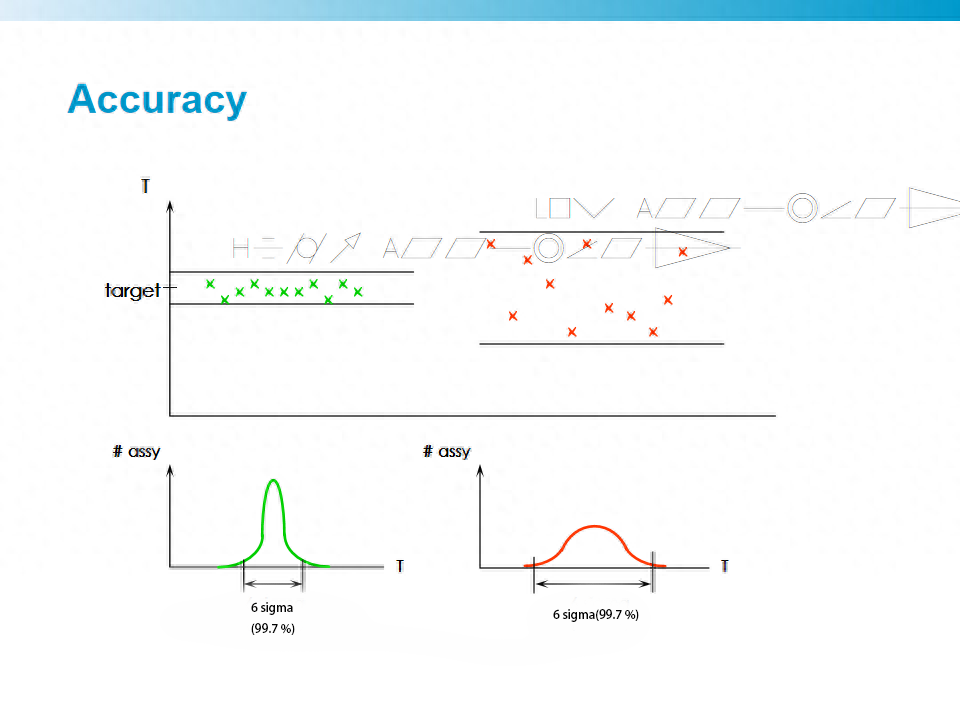

In many cases, the torque value during the production process and the torque value detected during offline testing are different. For example, the torque displayed on the controller is 100Nm, and the torque value detected after tightening is only 80Nm. So, which torque value is what we need to focus on? Let’s first clarify the torque values under different states. The manufacturing process department sets the parameters of the electric tightening gun based on the torque values on the drawings. The peak value displayed on the electric tightening gun at the moment of tightening is the dynamic torque, which is measured during the tightening process. For component assembly, dynamic torque is the input of the engineering research and development department to the manufacturing process, rather than the requirement for tightening results.

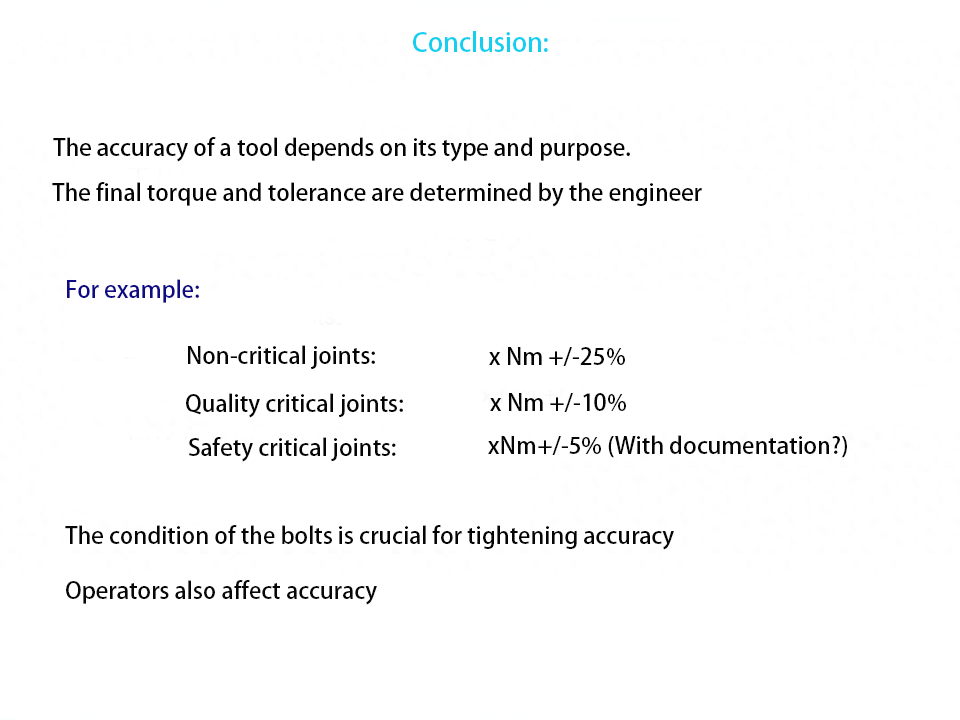

The dynamic torque is controlled by a tool setting mechanism or sensor, with high accuracy and high equipment cost. Due to the peak value during the rotation process, it cannot be visually displayed as the final tightening effect. So, the question arises, how do we know that the bolts or nuts have truly been tightened and meet the requirements when the electric gun reaches the set torque? At this point, the concept of static torque arises and regular spot checks must be conducted during the production process. Static torque is generally a re inspection of the bolt tightening point after tightening to confirm the attenuation of tightening torque. Static torque tightening is measured after tightening. In some cases, it is also referred to as residual torque.

Static torque mostly relies on manual detection, with simple detection tools, convenient operation, low equipment cost, and a more intuitive display of the final tightening effect. In short, dynamic torque is used for production and static torque is used for inspection.

2.Tools and methods for static torque detection

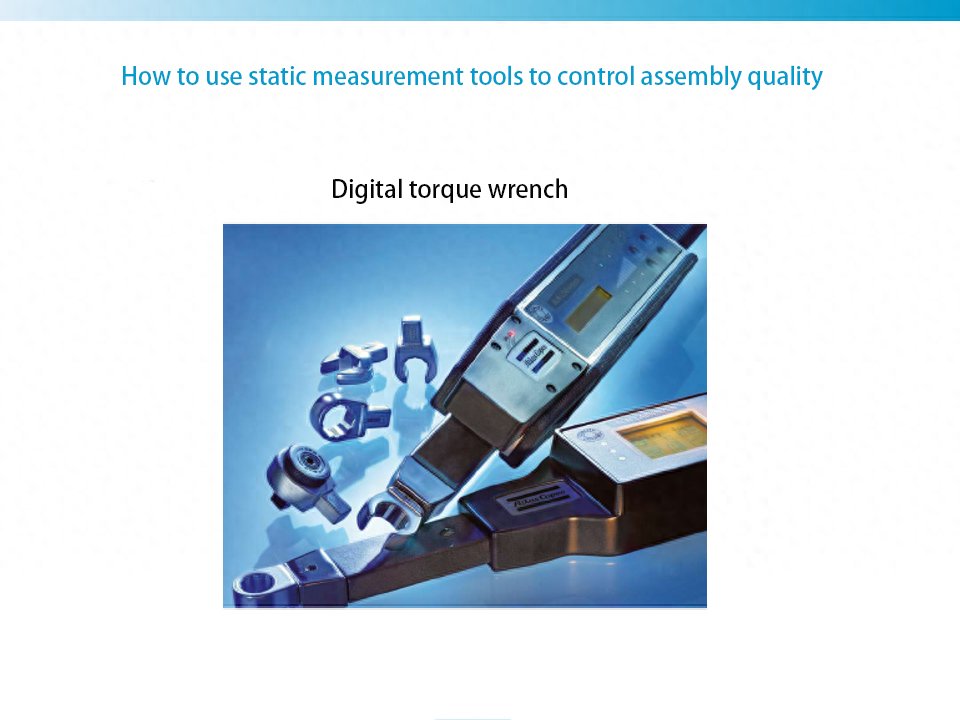

Static torque wrenches are generally divided into two types: dial type torque wrenches and digital display type torque wrenches. The dial type torque wrench is cheap, but its accuracy is low.

The digital detection wrench is equipped with a sensor and can set the angle. The accuracy is much higher than that of dial wrenches, and of course, the price is also much higher.

3.Measurement method for static torque

【1】Loosening method

【2】Tightening method

【3】Reset method

【4】Torque detection method

Post time: Oct-10-2023