Fastener function introduction

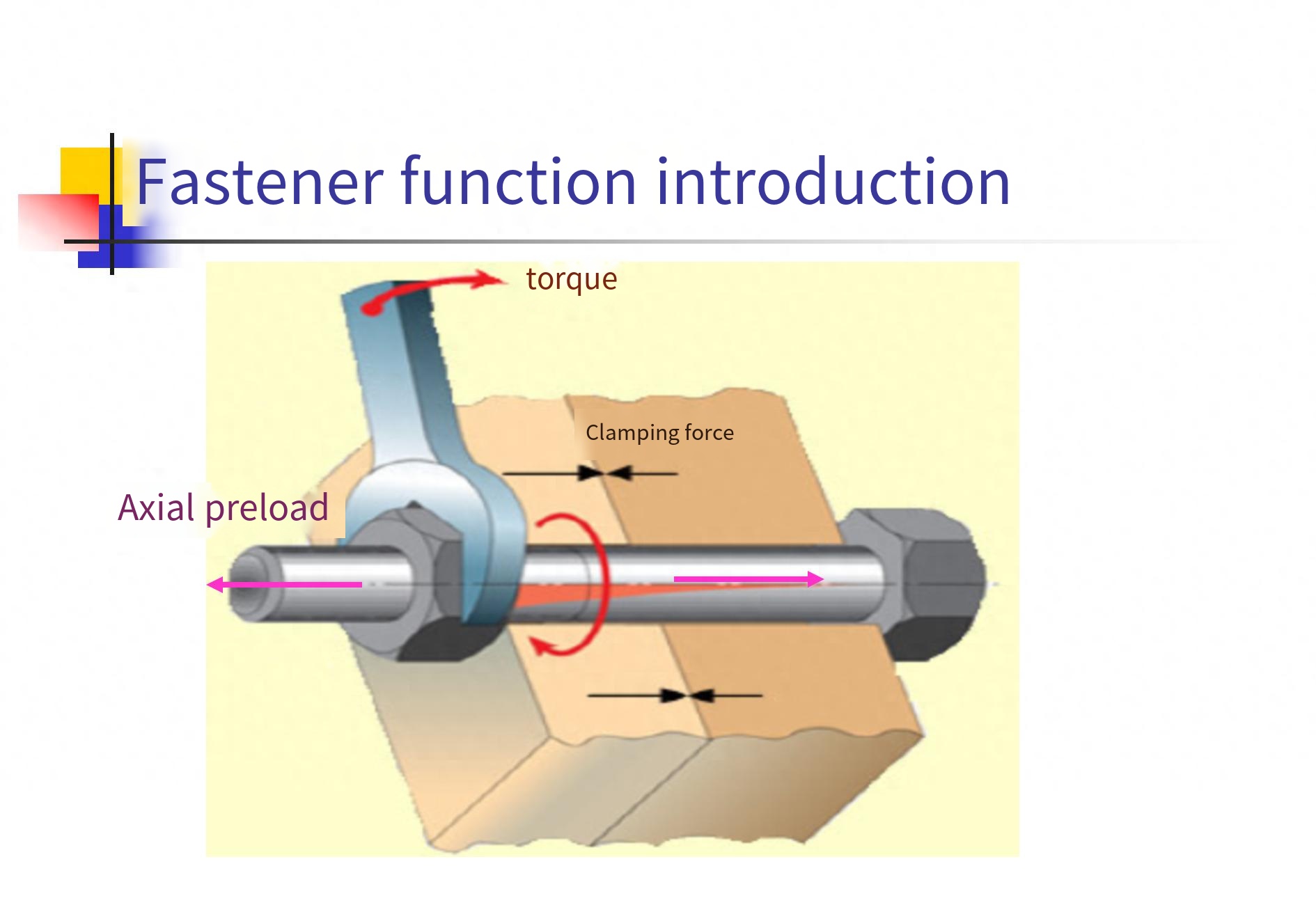

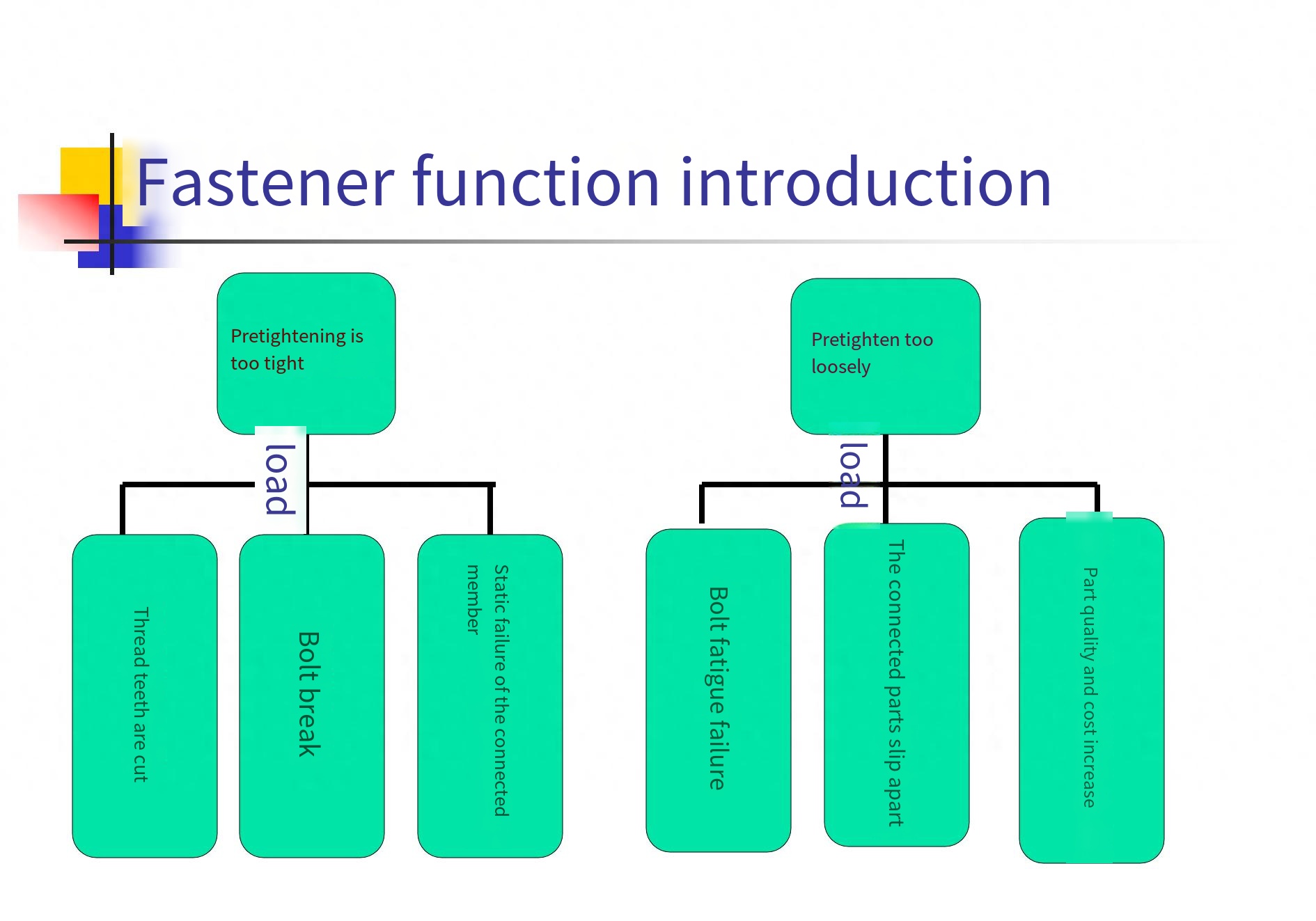

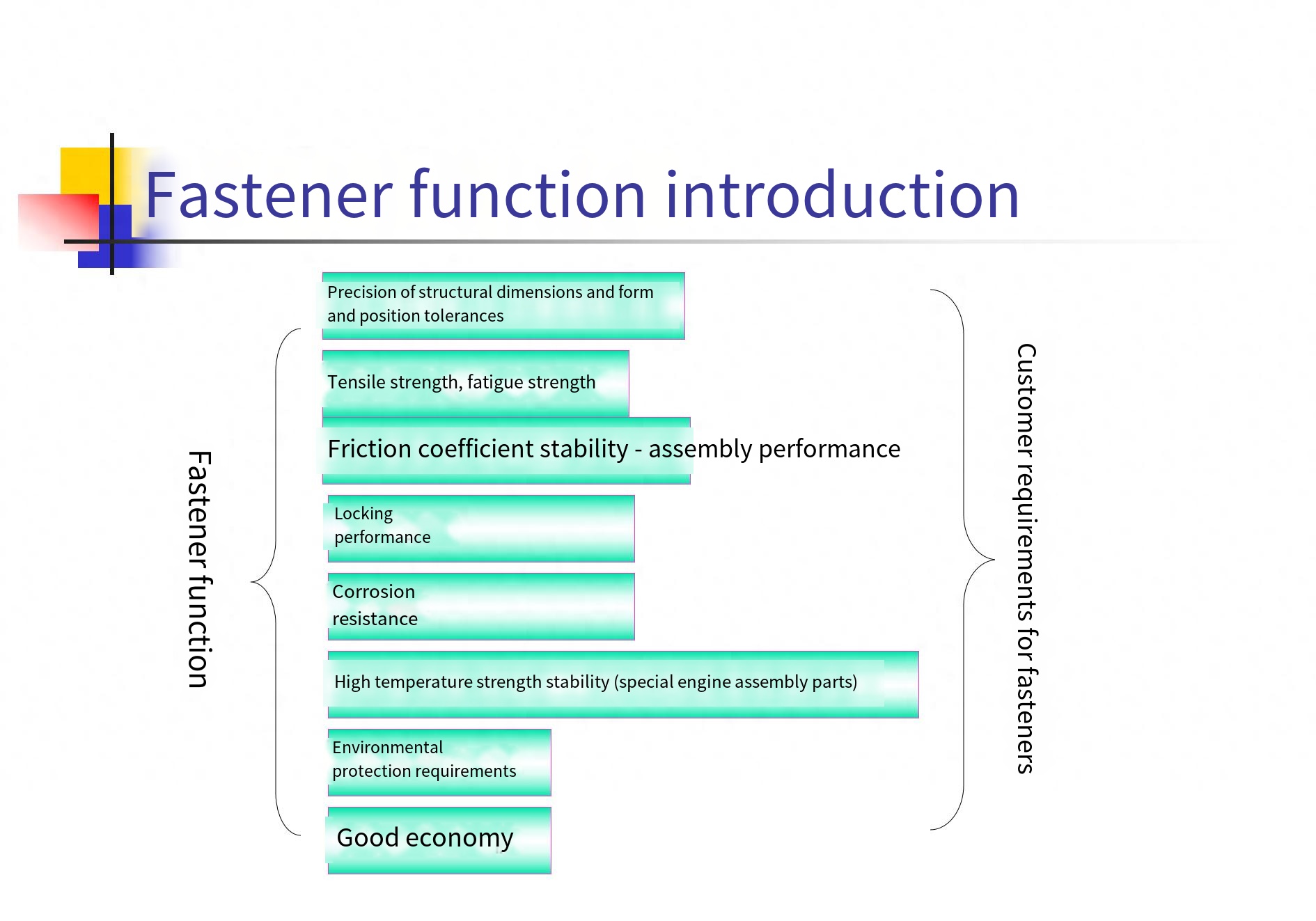

Fasteners are divided into threaded fasteners and non-threaded fasteners, non-threaded fasteners mainly refer to rivets, welded pins, connecting pins, etc., the engine in addition to the use of non-threaded fasteners, the vast majority are threaded fasteners. The so-called threaded connection is the use of threaded fasteners to clamp two or more connected parts together, in order to resist various external loads, and the connected parts do not separate, do not slip, or the joint surface does not leak. For this reason, before applying the external load, the threaded fasteners need to be tightened to tighten the connected parts. The tightening of threaded fasteners is called pretightening, and the force is called axial pretightening.

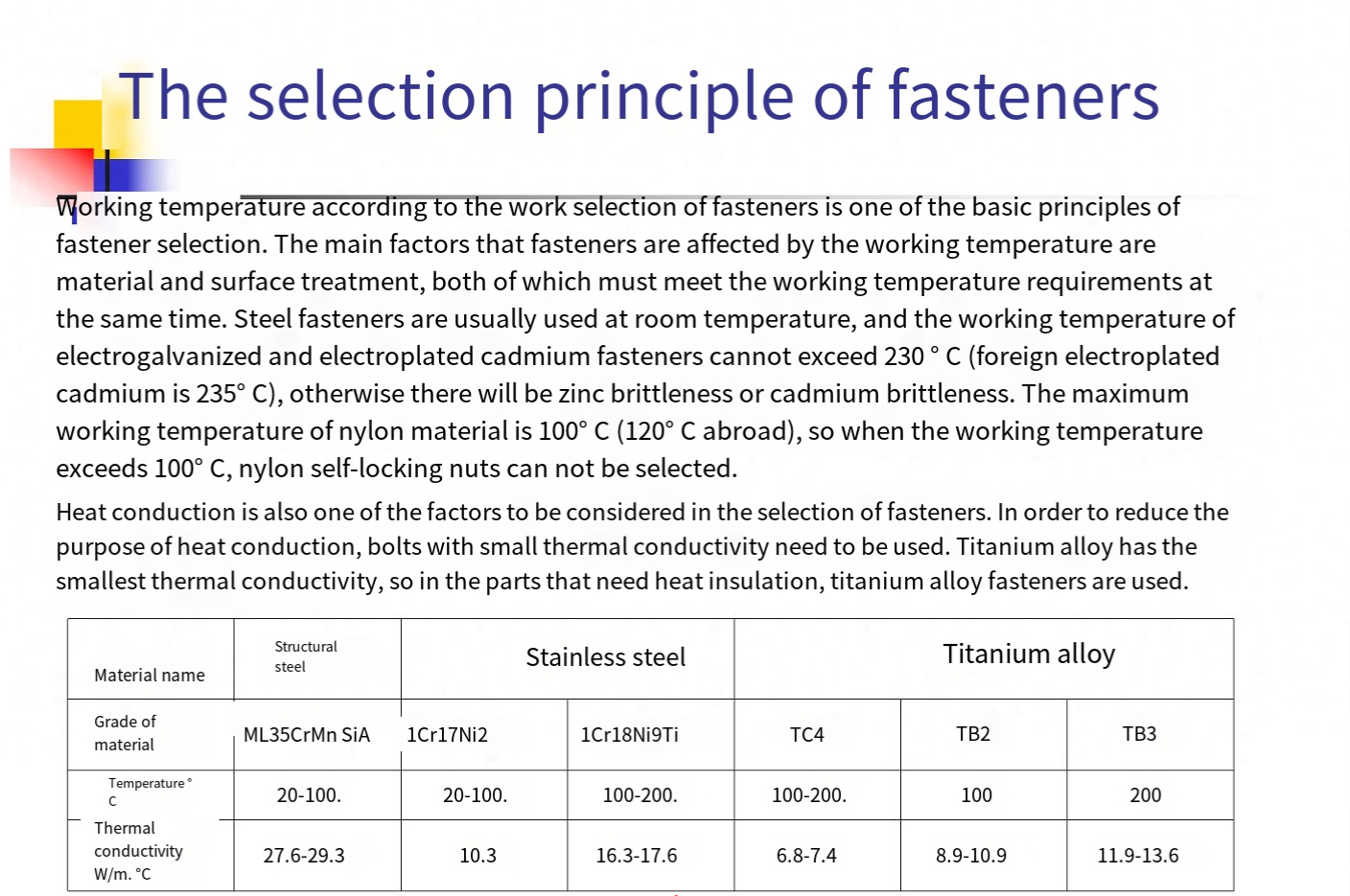

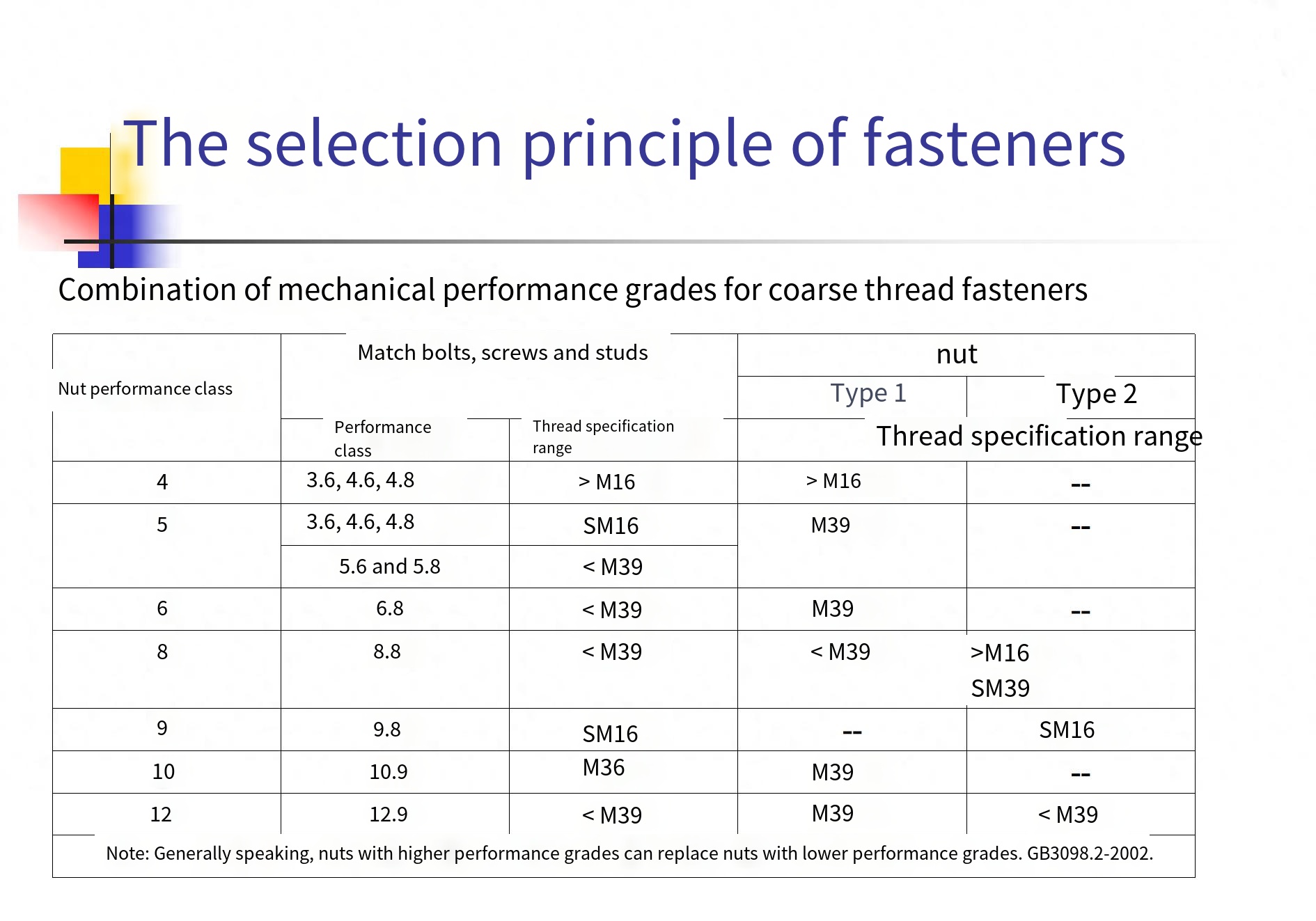

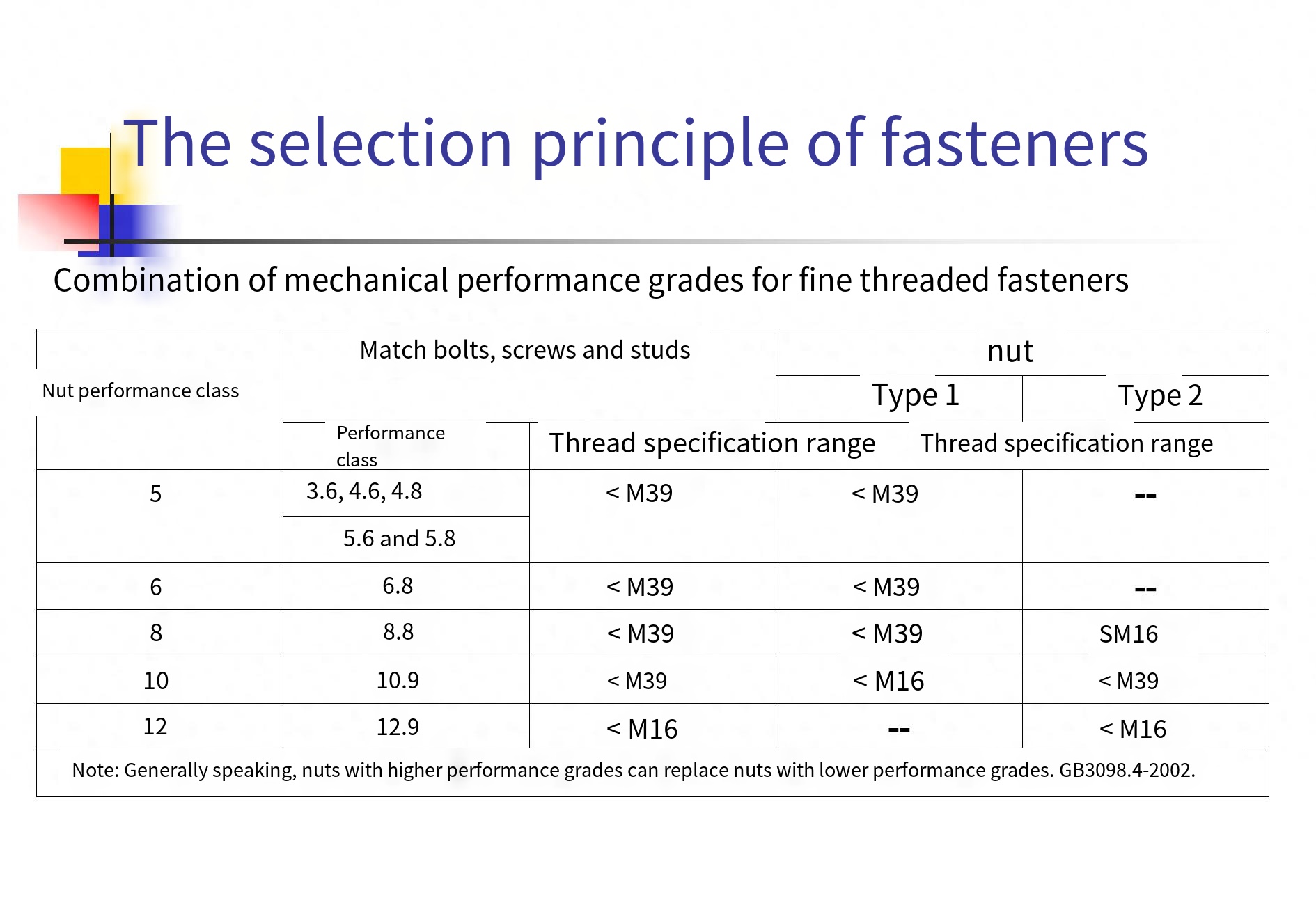

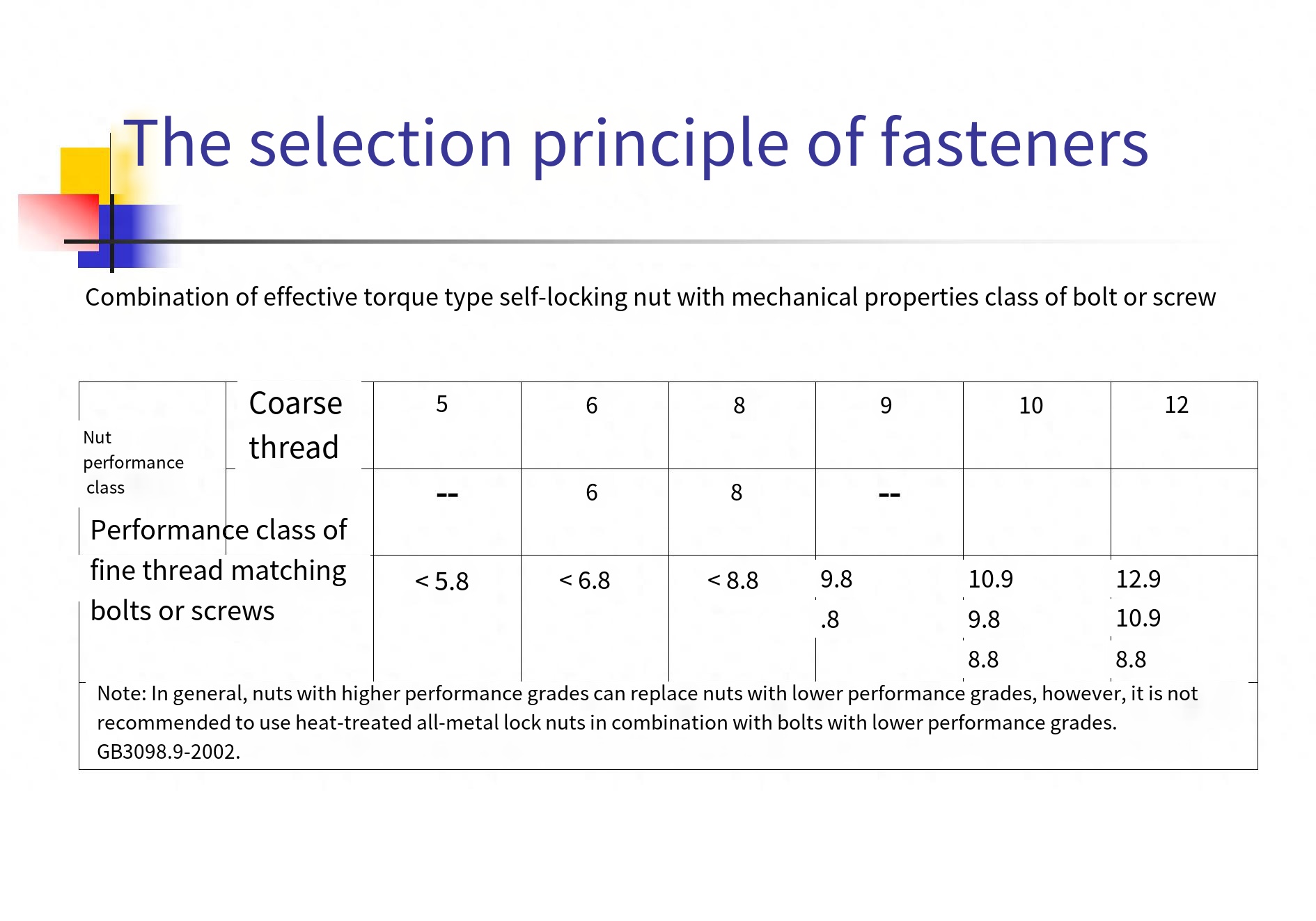

The selection principle of fasteners

Selection of fastener specificationsAfter selecting the variety of fasteners, the required specifications should also be selected in each variety. The specifications should be determined according to the requirements of the project or production and product for the connection design, and the principles to be considered generally have the following 3:Fastener specifications (including diameter and length) should be selected in the series listed in the fastener standard. If the standard has more than two size series, the first series or commodity specification series should be considered.Generally, it is not appropriate to choose length specifications other than those specified in the standard. When the bolt matches the nut, the length of the bolt should follow the principle that the bolt extends out of the nut 2-3 times the pitch (including chamfer), but the total length of the bolt should not be greater than 10d (d is the nominal diameter of the bolt).From economic considerations, the specifications of fasteners should be reduced as much as possible. For the same project or product, on the basis of investigation and research, the optimal range of fastener specifications can be determined, and the specifications within the optimal range can be selected as far as possible. I visited the United States Peka company heavy truck assembly line feeling very deep: rear axle part: M16 specification fine tooth flange bolts, the length has several specifications; The frame is mainly composed of M16 coarse teeth 10.9 bolts with all metal nuts, the length has several specifications, and the nuts are exactly the same; There are 3 kinds of head screws in the cab, the length of each head screw is basically the same, and the degree of standardization is very high.

Post time: Sep-12-2023