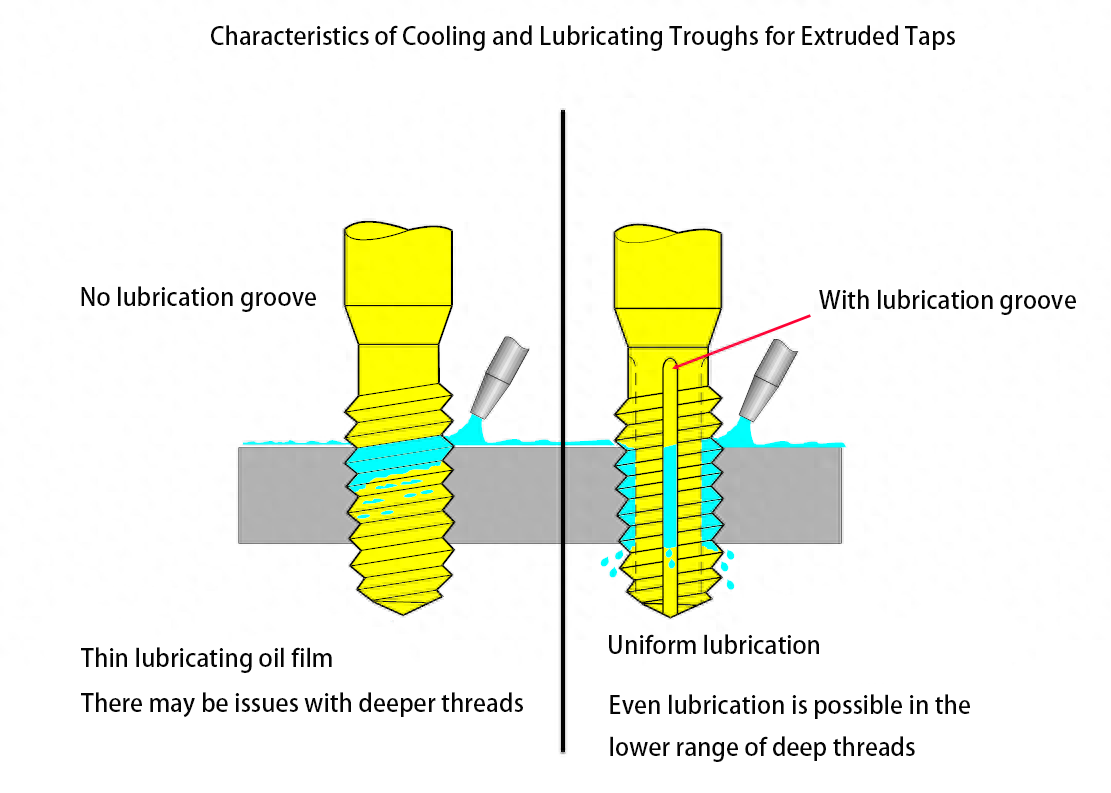

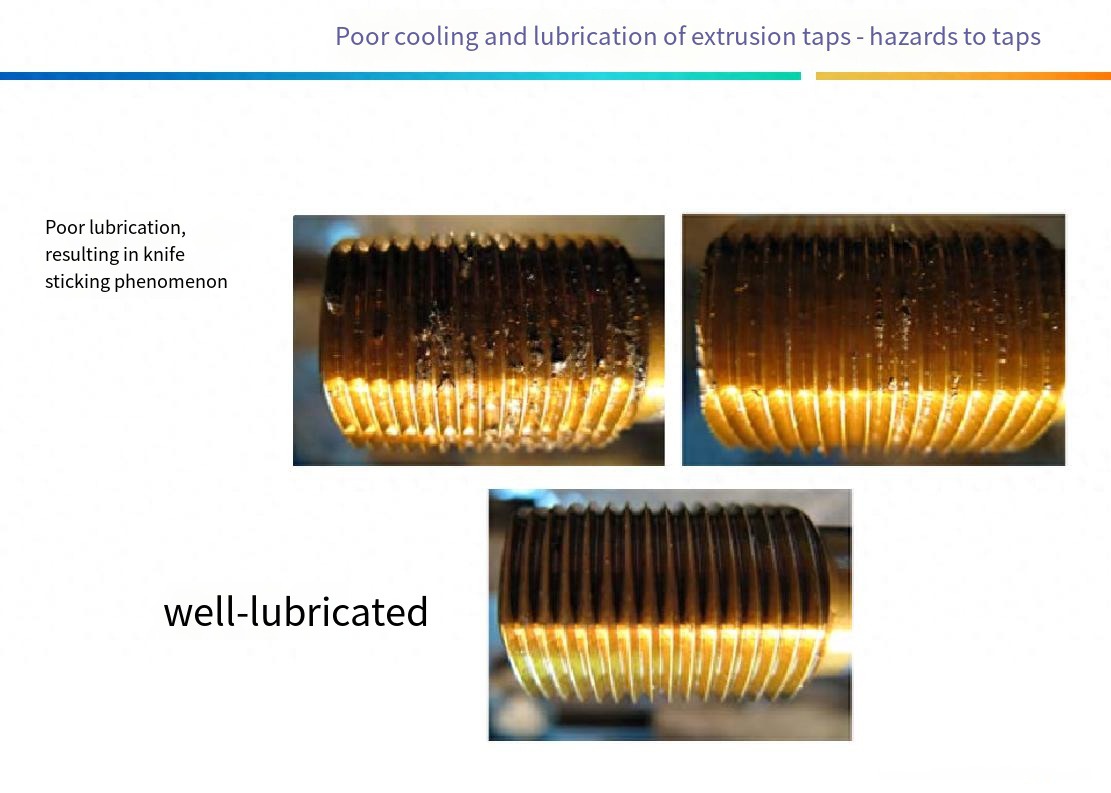

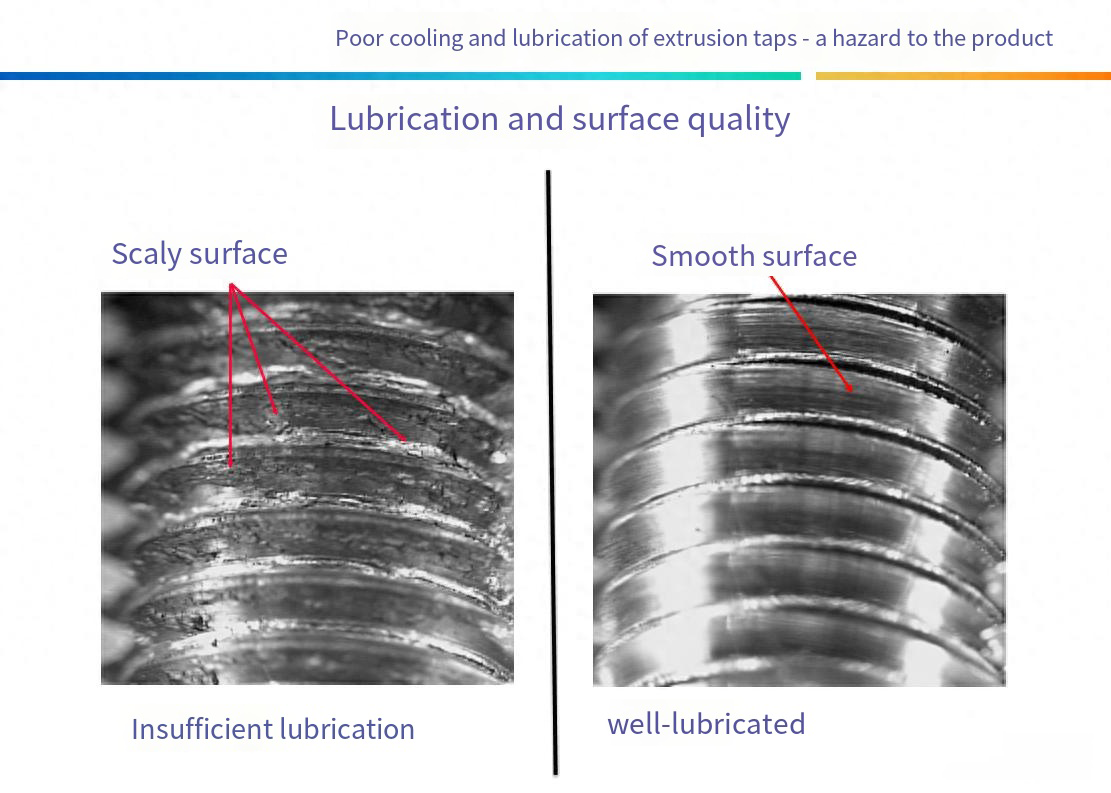

Coolant lubricant

In the process of internal thread cold extrusion, the selection of suitable cooling lubricant can greatly reduce the direct wear of the working surface of the extrusion tap and extend its life.

Extrusion tap will be subjected to a lot of friction resistance, conditions generally use cutting oil rather than water-soluble cutting fluid.

Feed rate

Feed speed of the squeeze tap.

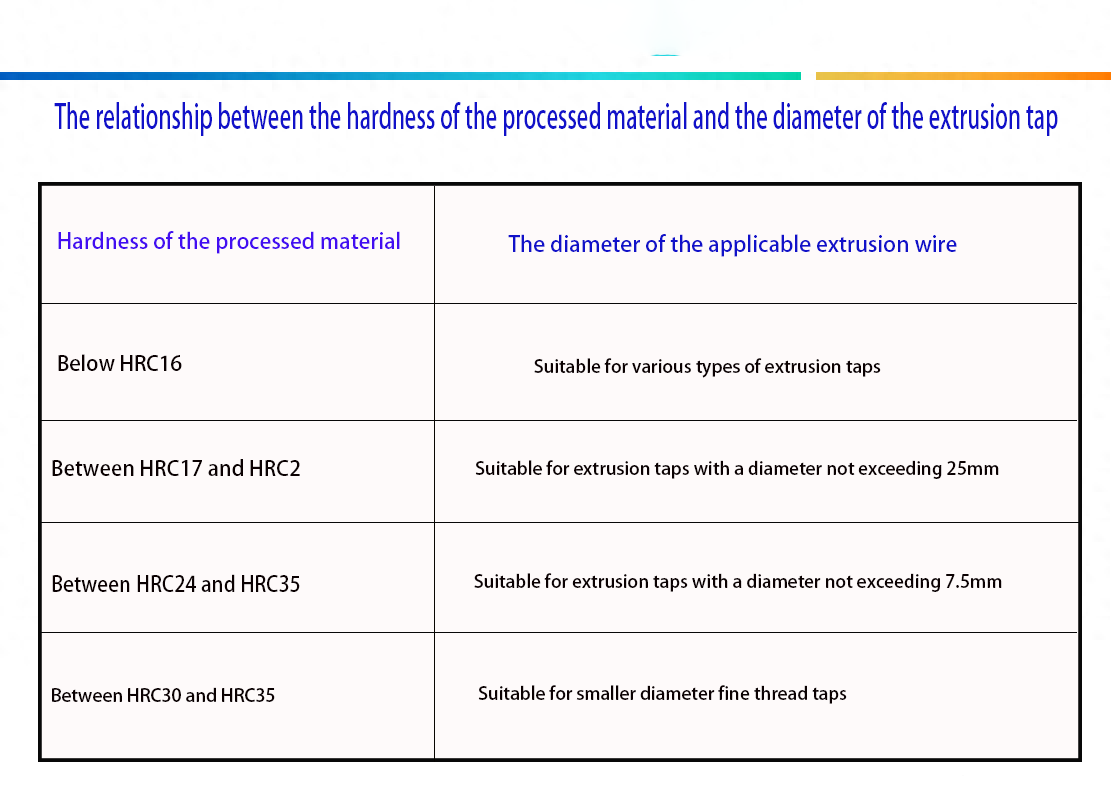

The tapping speed of the extruded tap depends on the diameter of the tap, the pitch of the thread, the hardness of the material to be machined and the coolant, and we generally use the same tapping speed as the cutting tap.

In the case of processing softer materials and fine thread (less than1.25mm), the speed can be increased to 1.5-2 times.

When processing some large diameter and coarse thread, due to the influence of tapping torque and lubrication effect, the tapping speed can be appropriately slowed down.

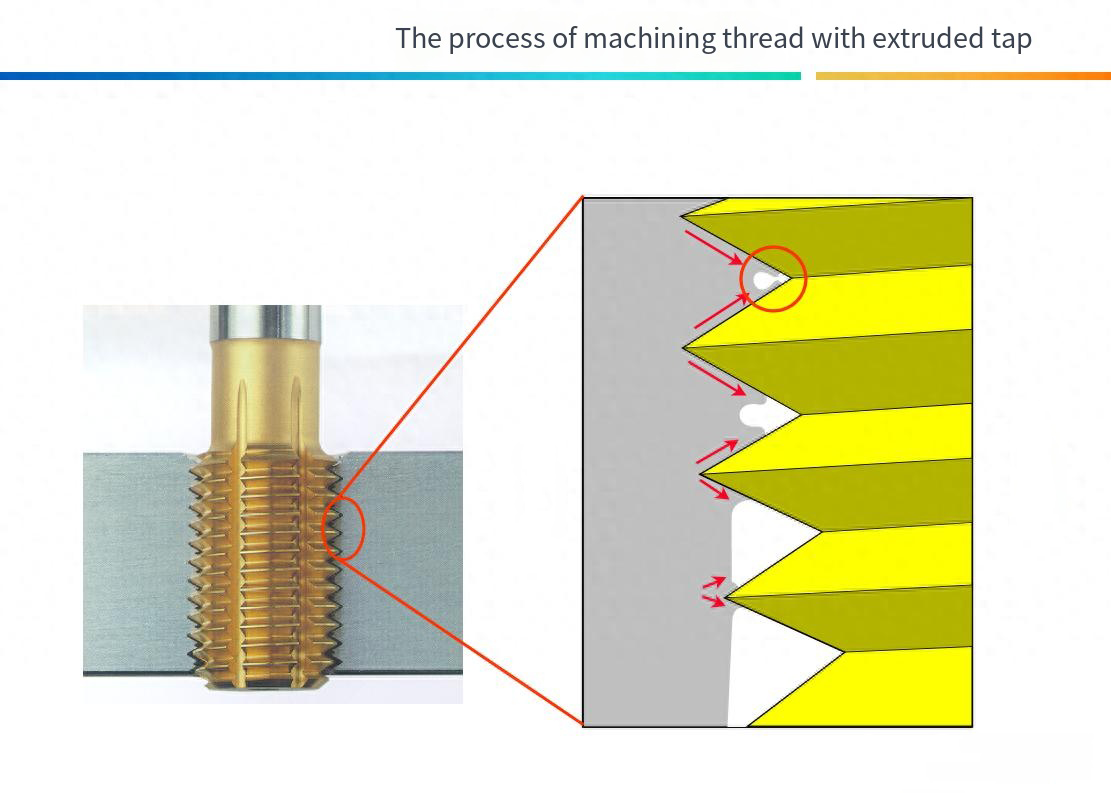

Advantages of extrusion tapping

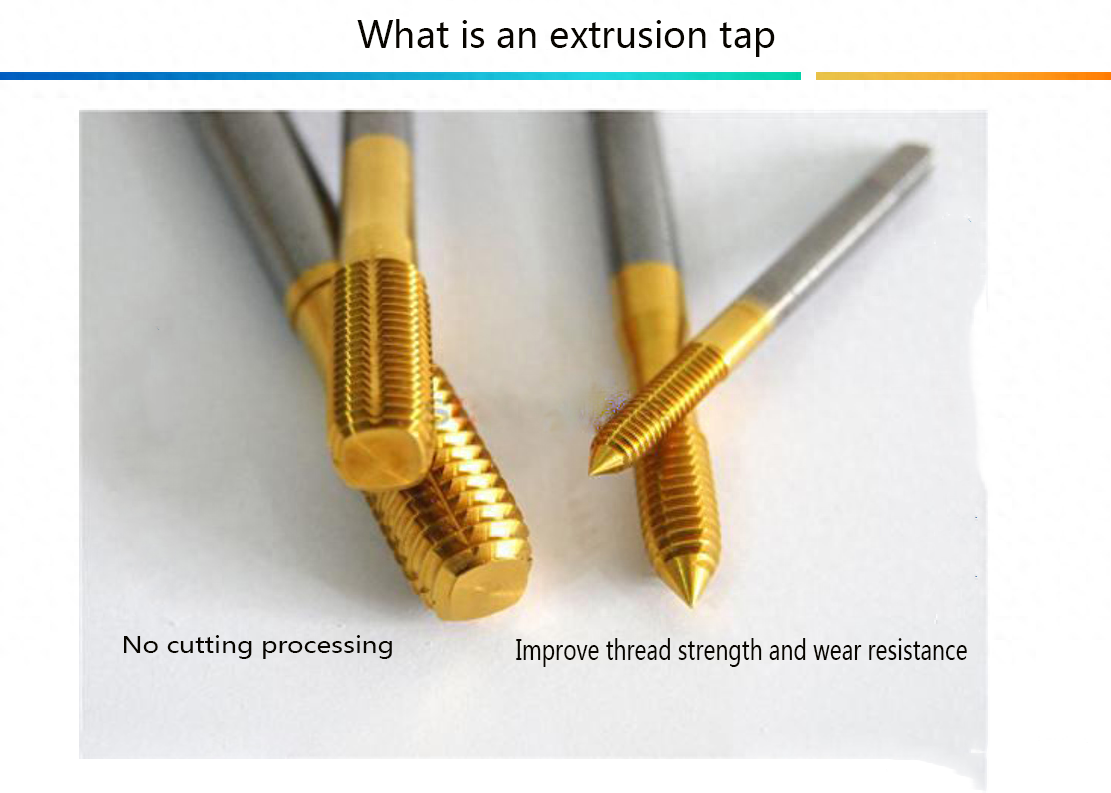

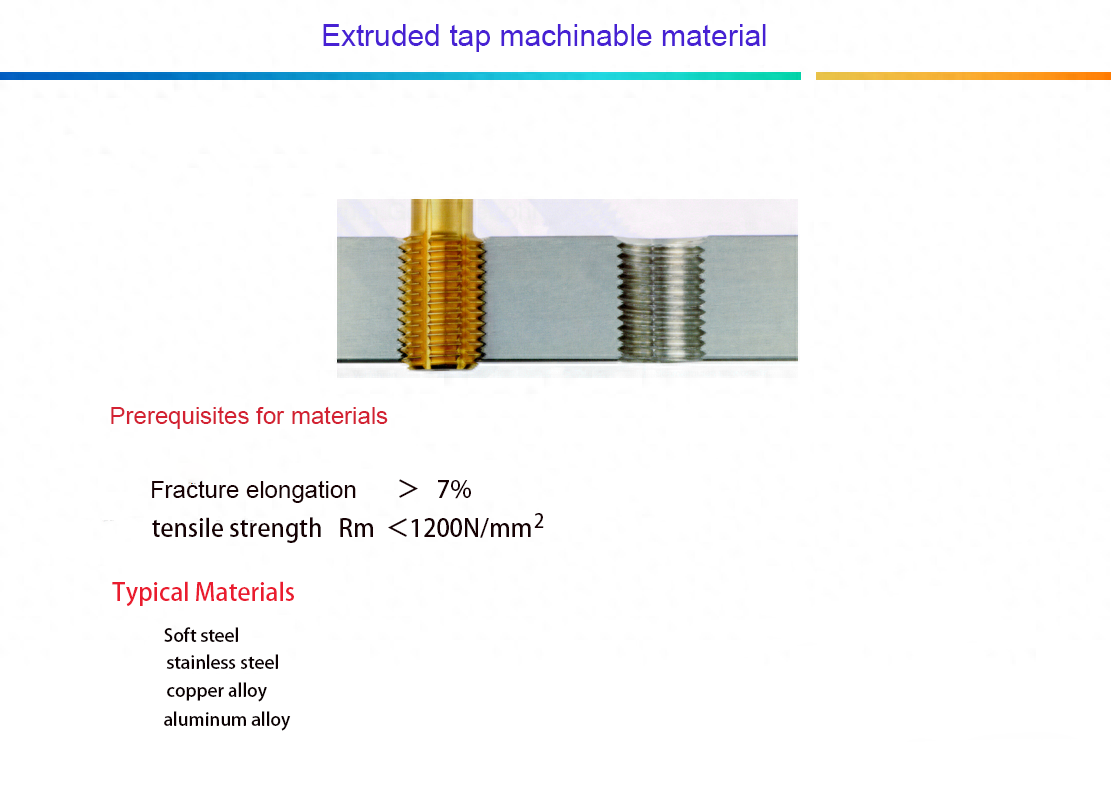

1. High precision of internal thread processed (up to H4 level).

2, the surface of the processed thread forms a hard layer, thereby improving the bearing capacity of the thread.

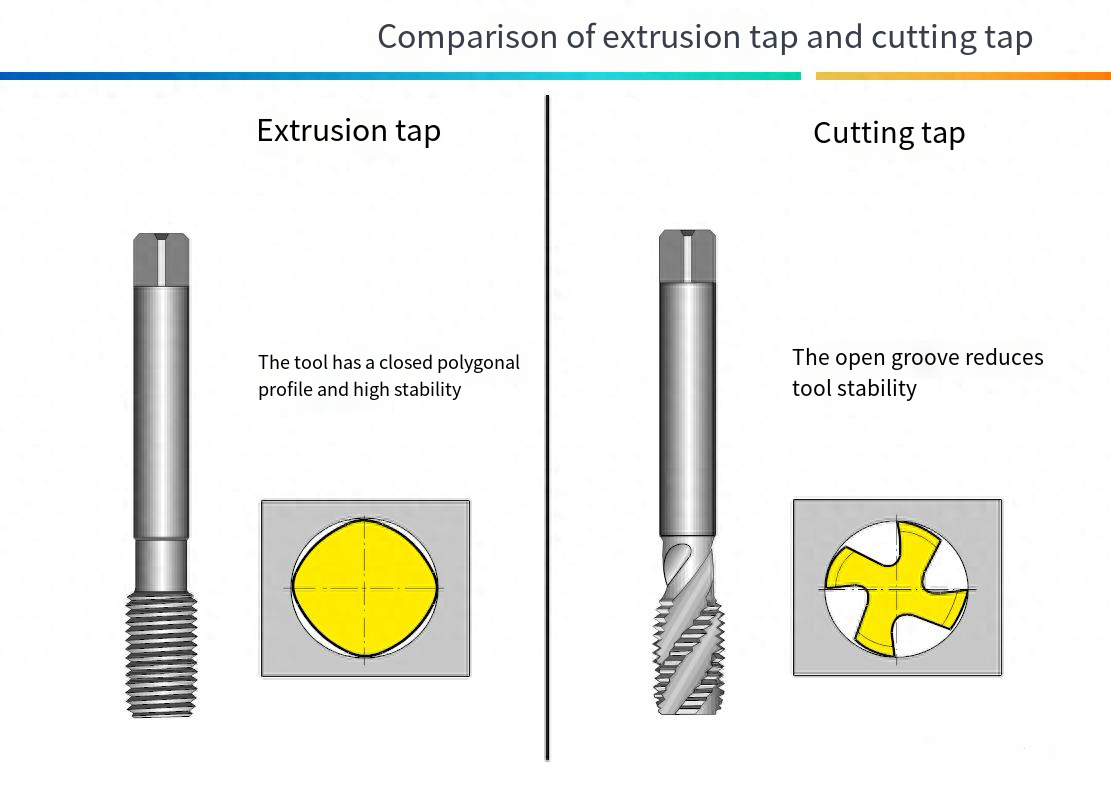

3, the extrusion tap has no chip groove, and the core cross-sectional area is large, which improves the strength and increases the life.

4, tapping does not produce burrs, surface roughness is good.

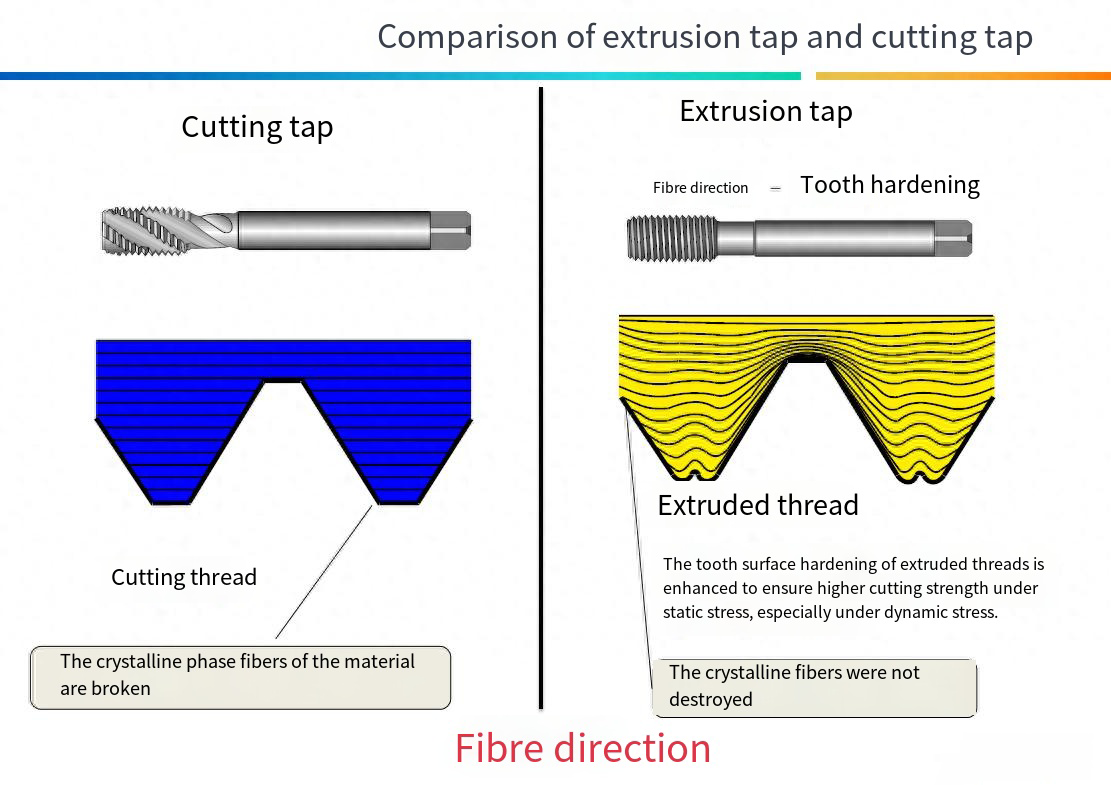

5. The grain fiber of the material is not cut, and the thread strength is 30-40% higher than that of the cutting thread.

6·Extruded cold work hardening using thread surface hardness than core 40-50% higher.

7. Short auxiliary working hours, high production efficiency

Post time: Oct-04-2023