As a commonly used tool in fixtures, bolts are widely used, but long-term use can also bring many problems, such as loose connections, insufficient clamping force, and rusting of bolts. During the processing and production of parts, the looseness of bolt connections can affect the quality and efficiency of processing. So how to prevent the bolts from loosening?

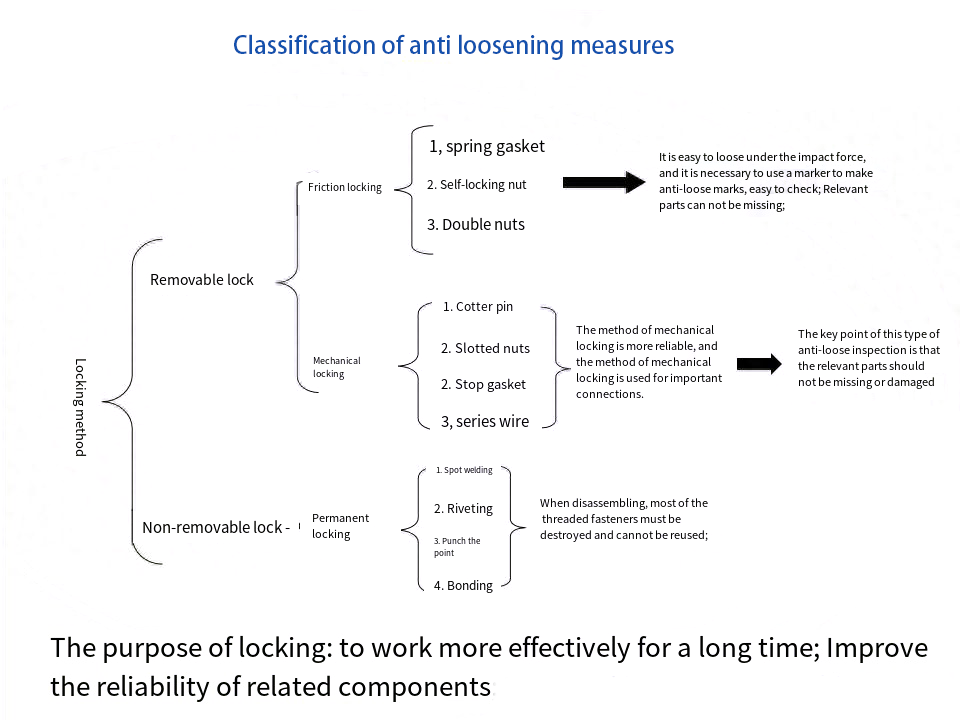

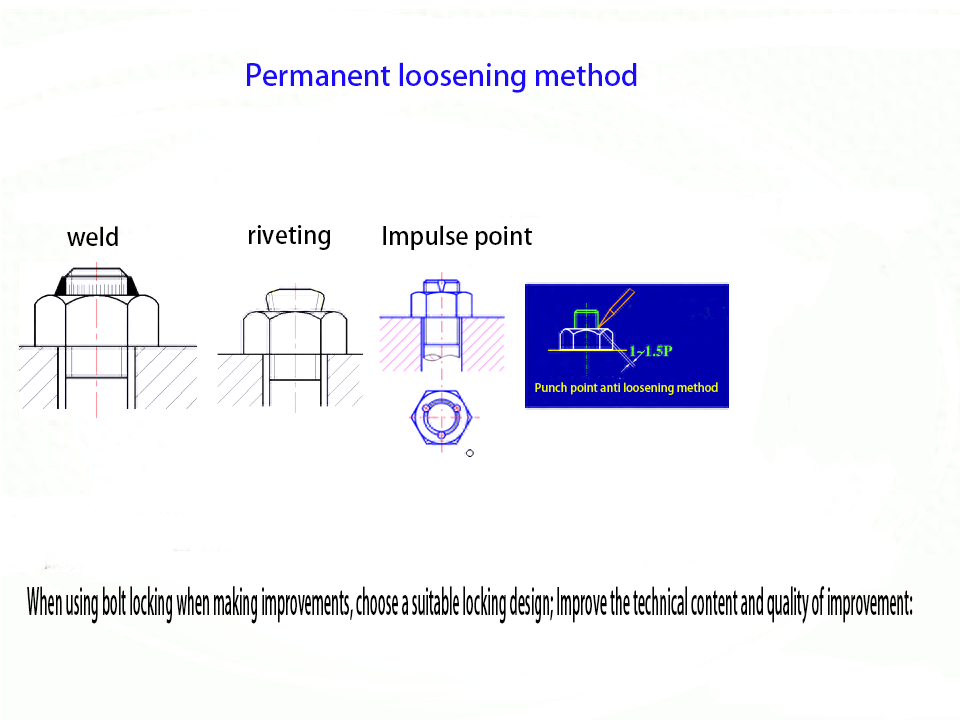

There are three commonly used anti loosening methods: friction anti loosening, mechanical anti loosening, and permanent anti loosening.

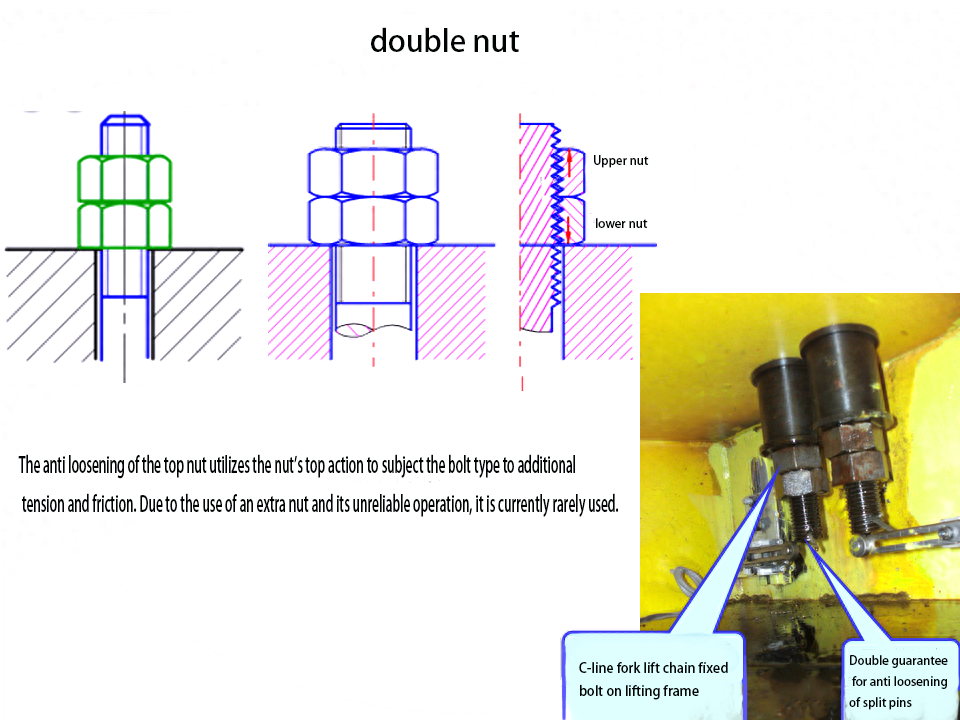

Double nut

Principle of top locking nut: When double nuts are locked, two friction surfaces are generated. The first friction surface is between the nut and the fastener, and the second friction surface is between the nut and the nut. During installation, the pre tightening force of the first friction surface is 80% of the second friction surface. When subjected to impact and vibration loads, the friction force on the first friction surface decreases and disappears, but at the same time, the first nut is compressed, causing further increase in the friction force on the second friction surface. Nut loosening must overcome the first and second friction forces, as the first friction force decreases while the second friction force increases. This way, the anti loosening effect will be better.

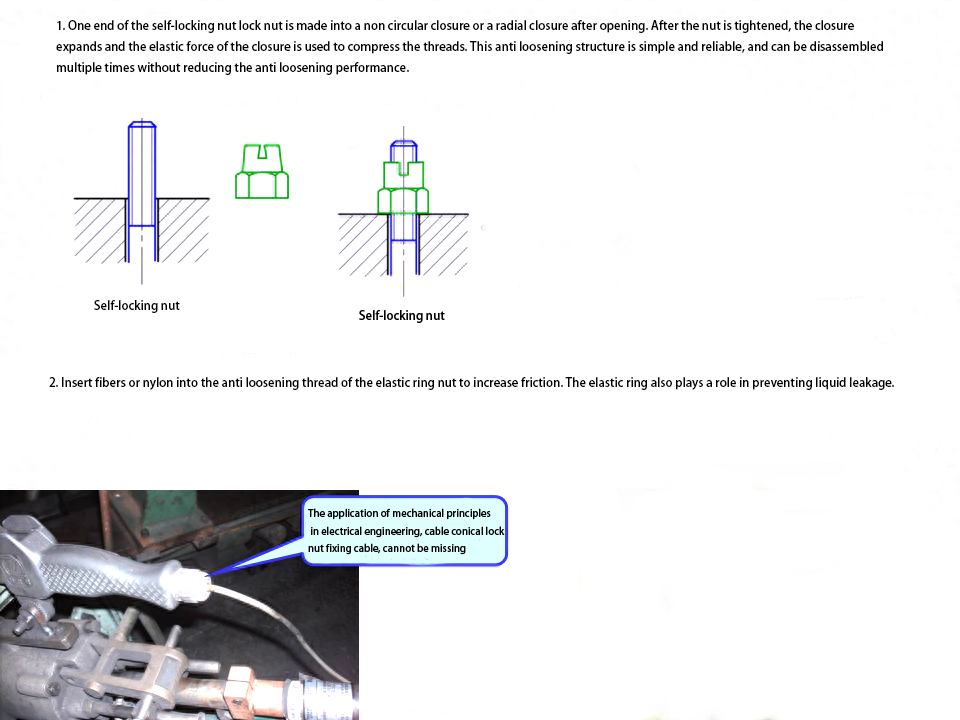

Self-locking nut

Self locking nuts generally rely on friction to self lock, and the 30 ° wedge thread anti loosening we mentioned above should belong to the category of self locking nuts.

Thread locking adhesive

Thread locking adhesive is an adhesive composed of (methyl) acrylate, initiator, promoter, stabilizer (polymerization inhibitor), dye, and filler in a certain proportion. For through-hole working conditions: Thread the bolt through the screw hole, apply thread locking adhesive to the thread of the engagement part, assemble the nut, and tighten it to the specified torque.

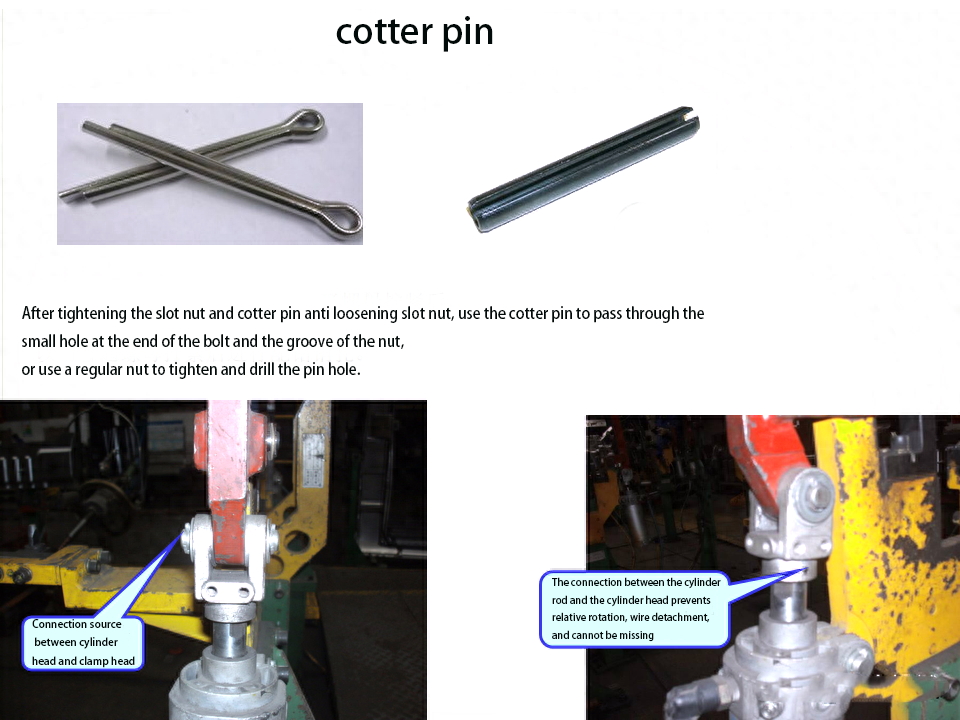

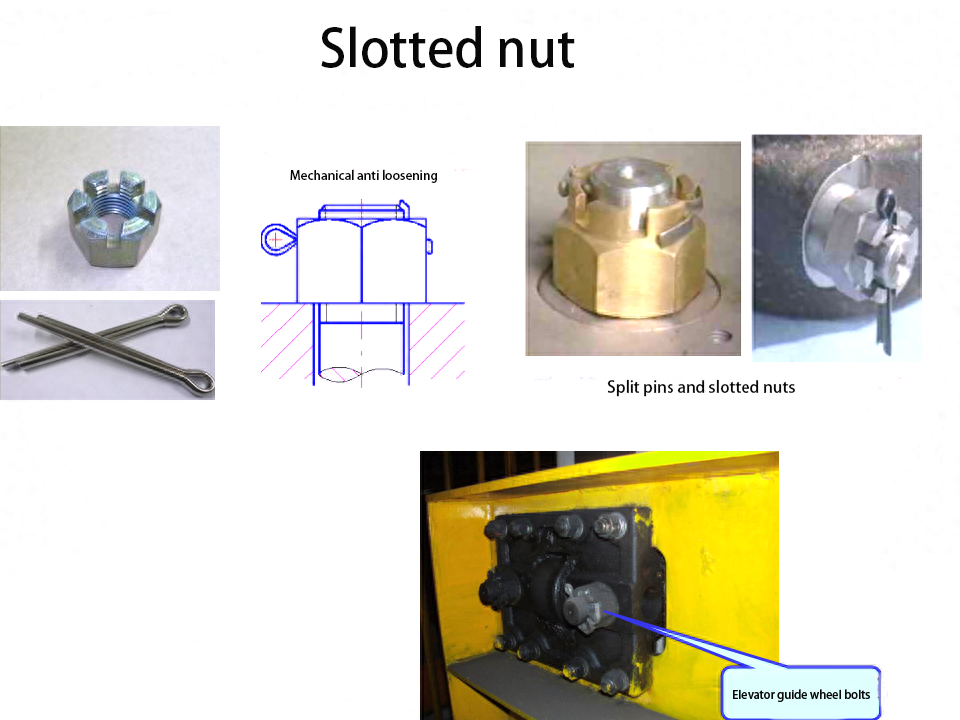

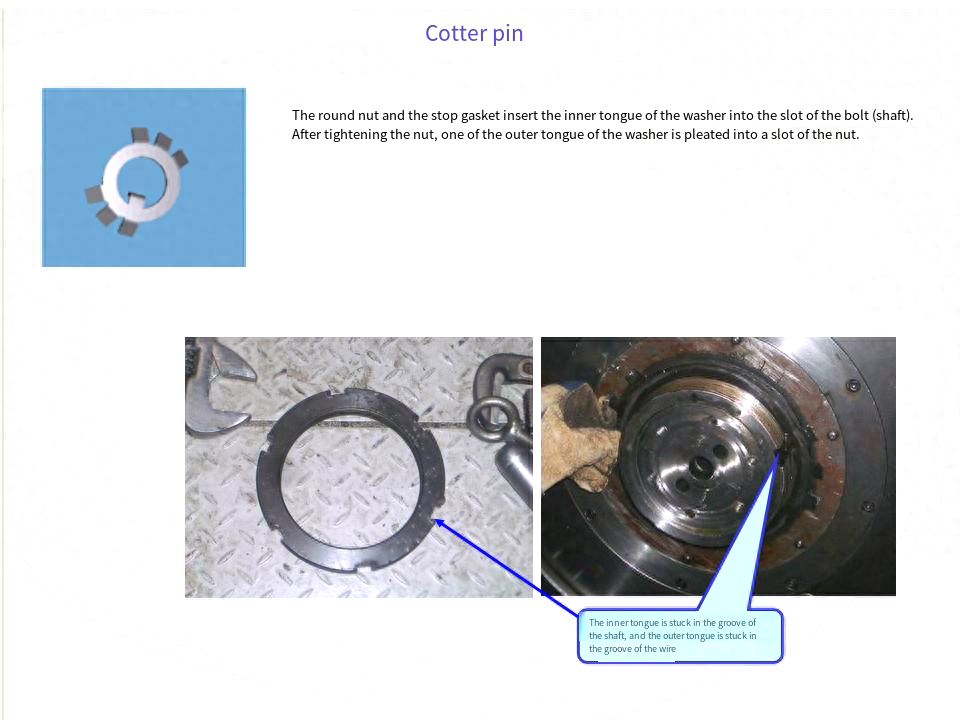

Split pins, slotted nuts

After tightening the nut, insert the cotter pin into the nut slot and the bolt tail hole, and pull the cotter pin tail open to prevent relative rotation between the nut and the bolt.

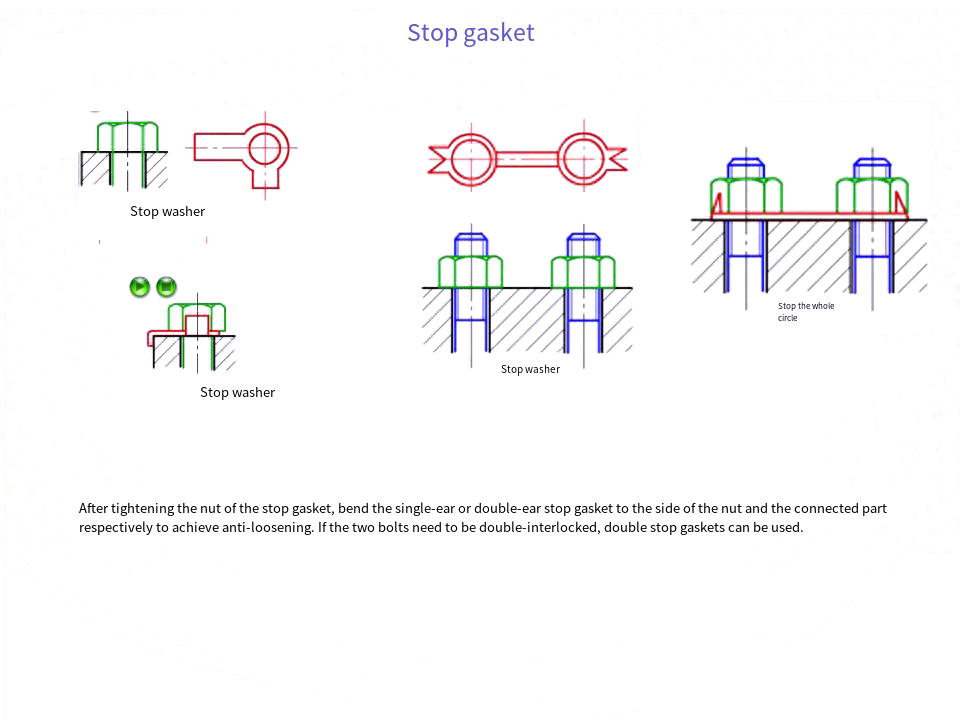

Stop washer

After tightening the nut, bend the single or double lug stop washer towards the side of the nut and the connecting piece respectively to lock the nut. If two bolts require double interlocking, a double brake washer can be used to brake the two nuts against each other.

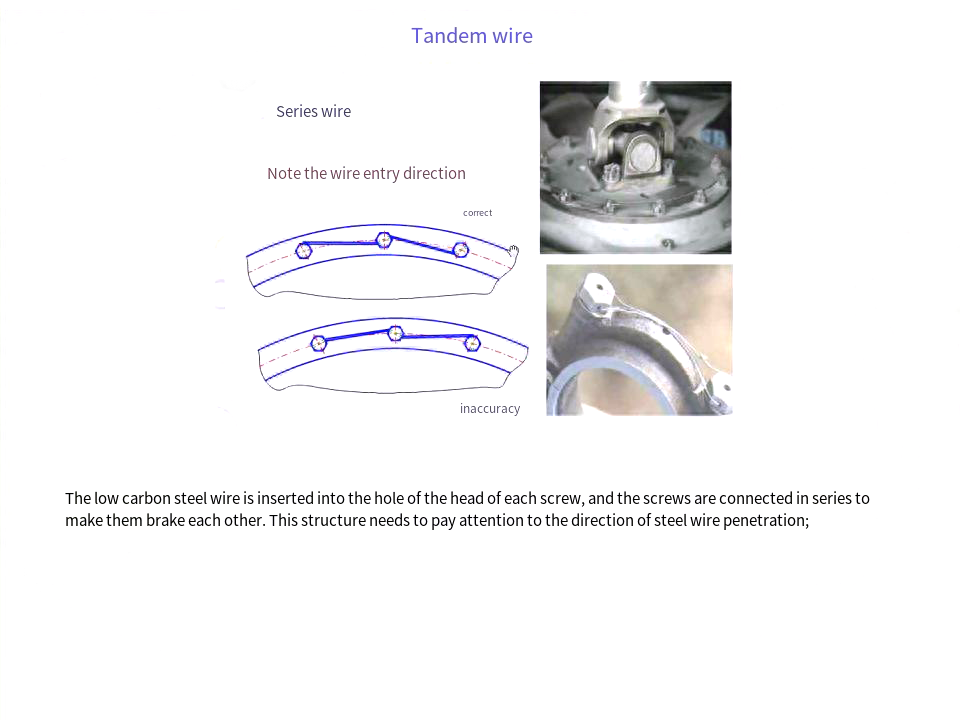

Tandem steel wire

Anti loosening series steel wire anti loosening is the process of threading the steel wire into the holes on the bolt head, connecting each bolt in series and exerting mutual restraint. This relaxation method is very reliable, but disassembly is quite troublesome.

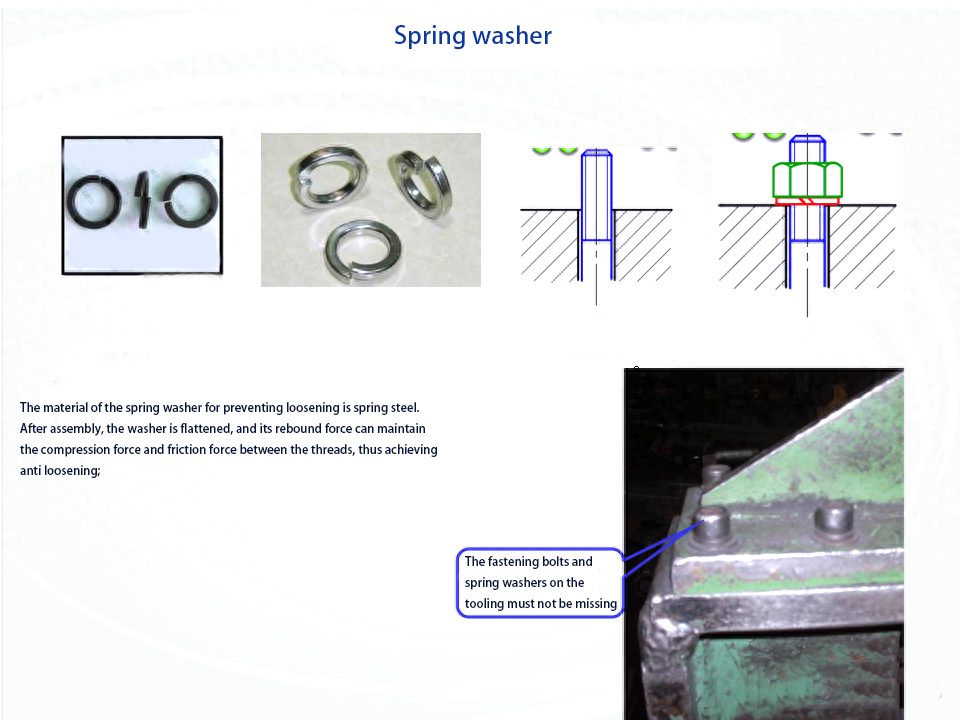

Spring washer

The anti loosening principle of spring washers is that after pressing the spring washer flat, the spring washer will generate a continuous elastic force, which will maintain a frictional force between the threaded connection pair of the nut and the bolt, generating a resistance torque to prevent the nut from loosening.

Hot melt fastening technology

The hot melt fastening technology does not require pre opening and can be directly tapped for connection under closed profi

Post time: Oct-17-2023