thread identification

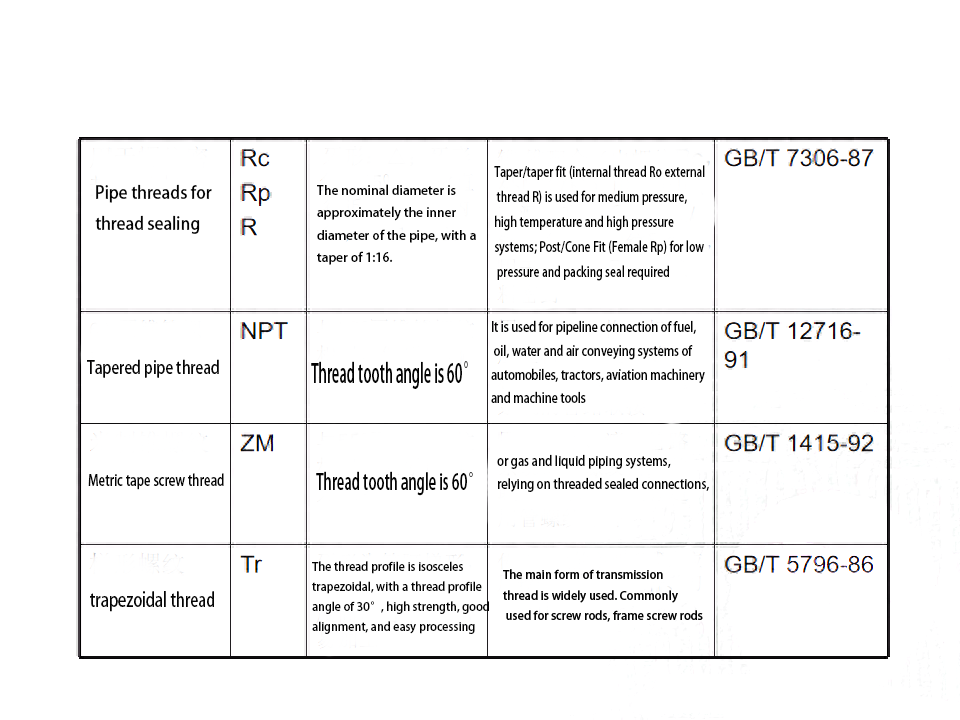

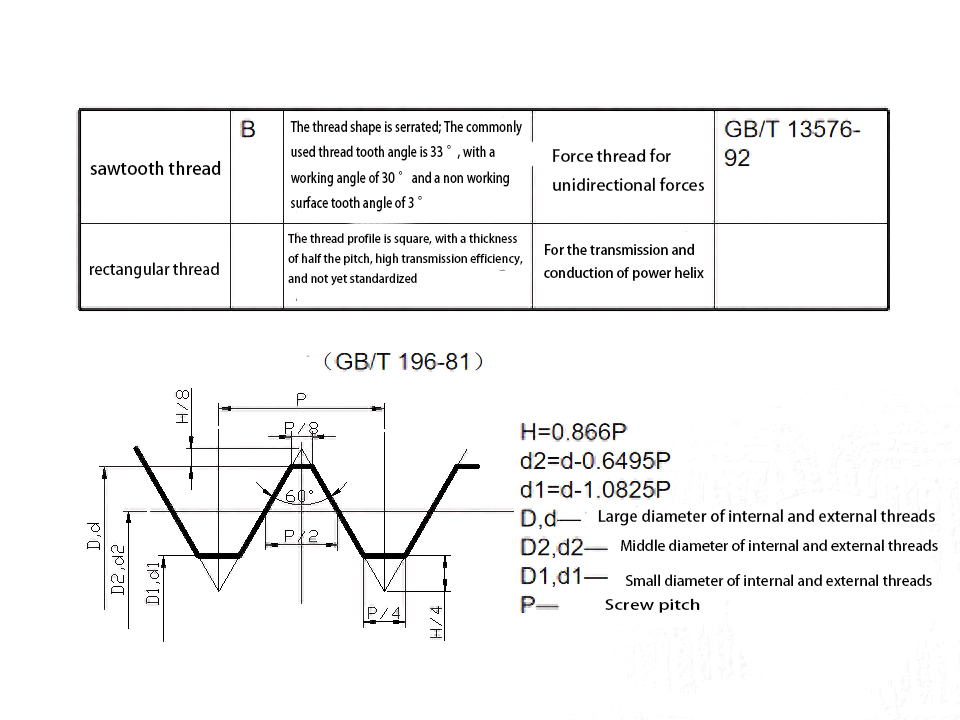

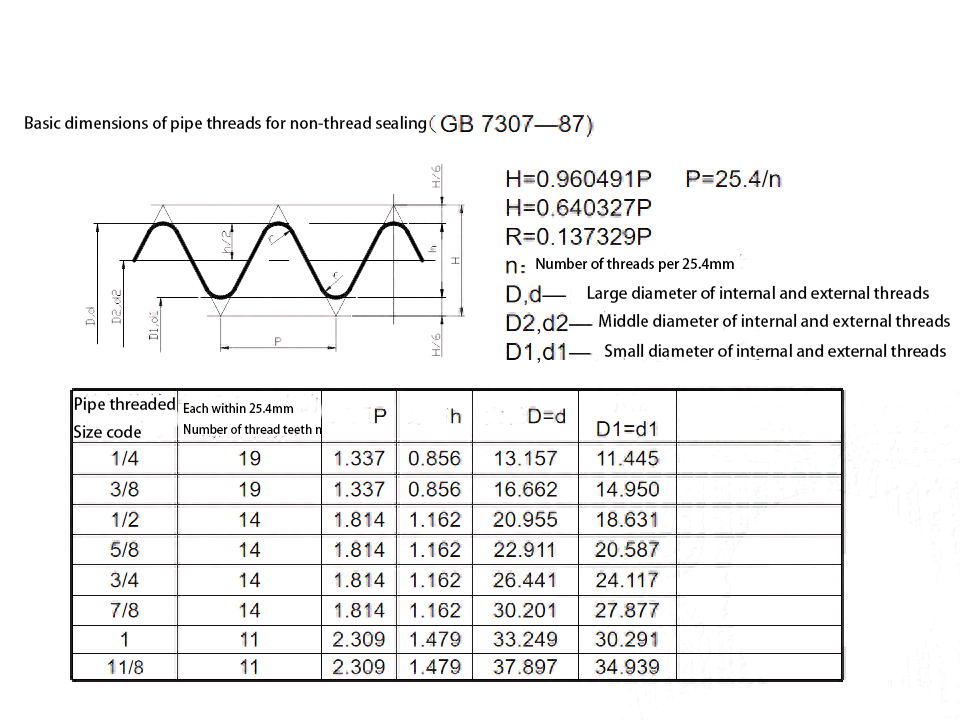

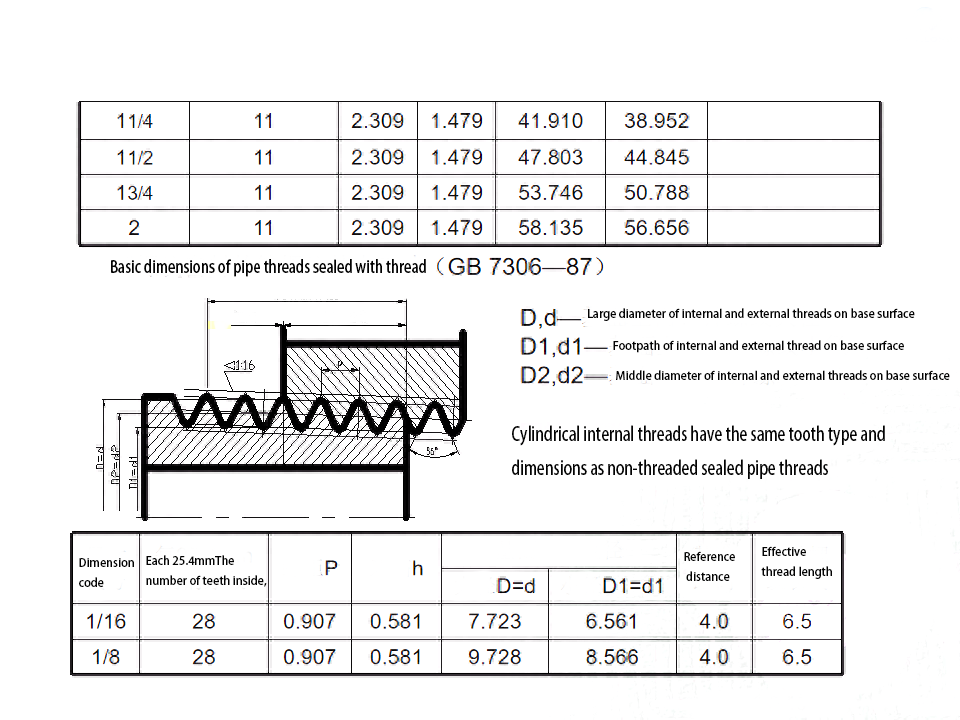

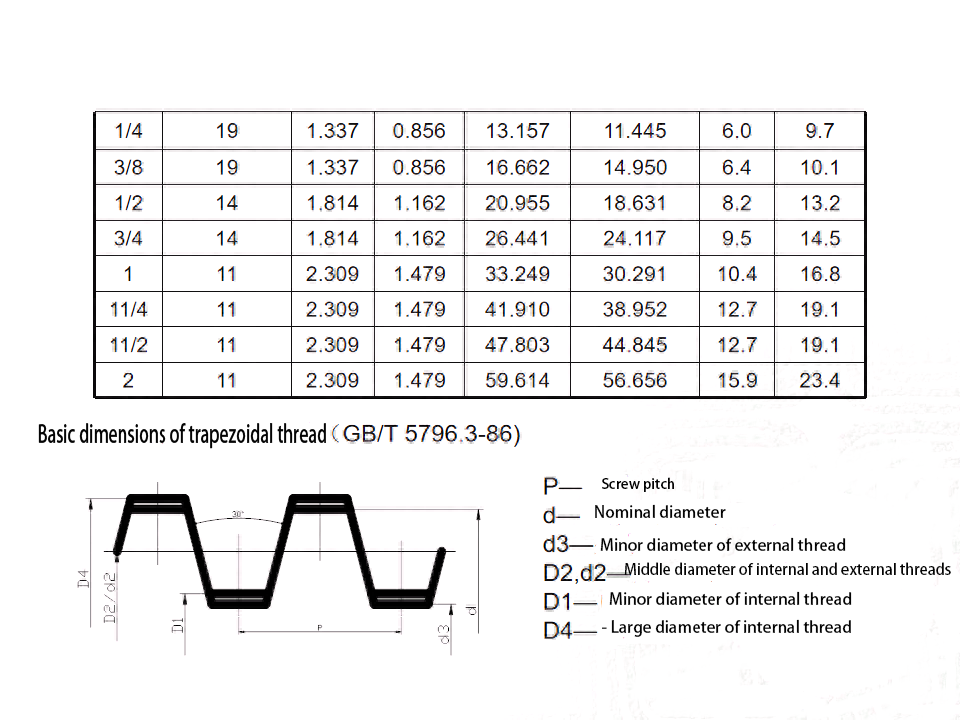

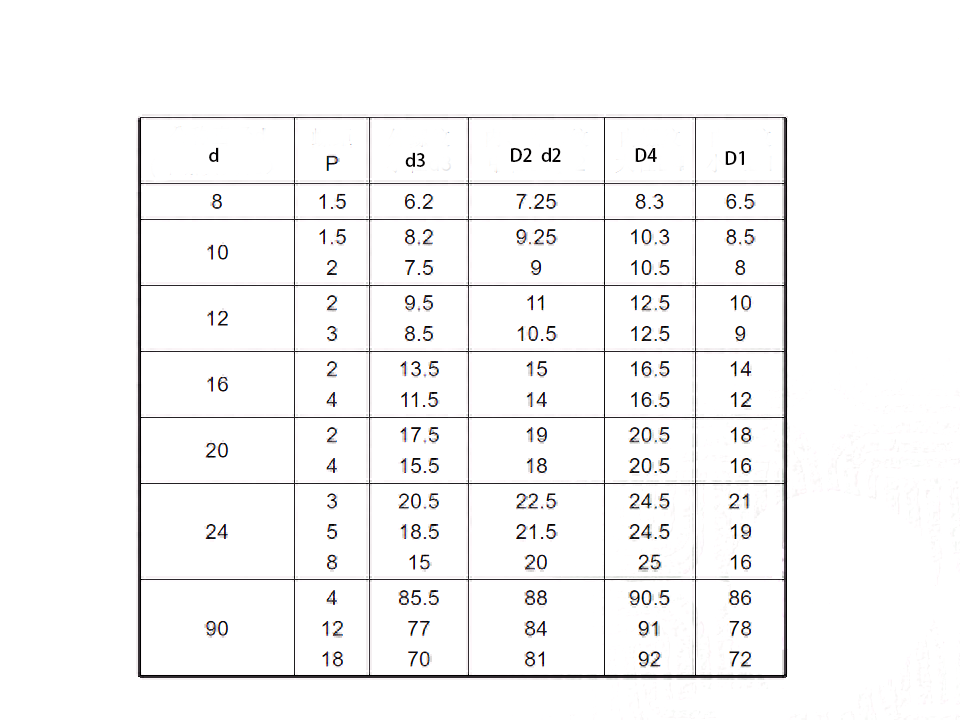

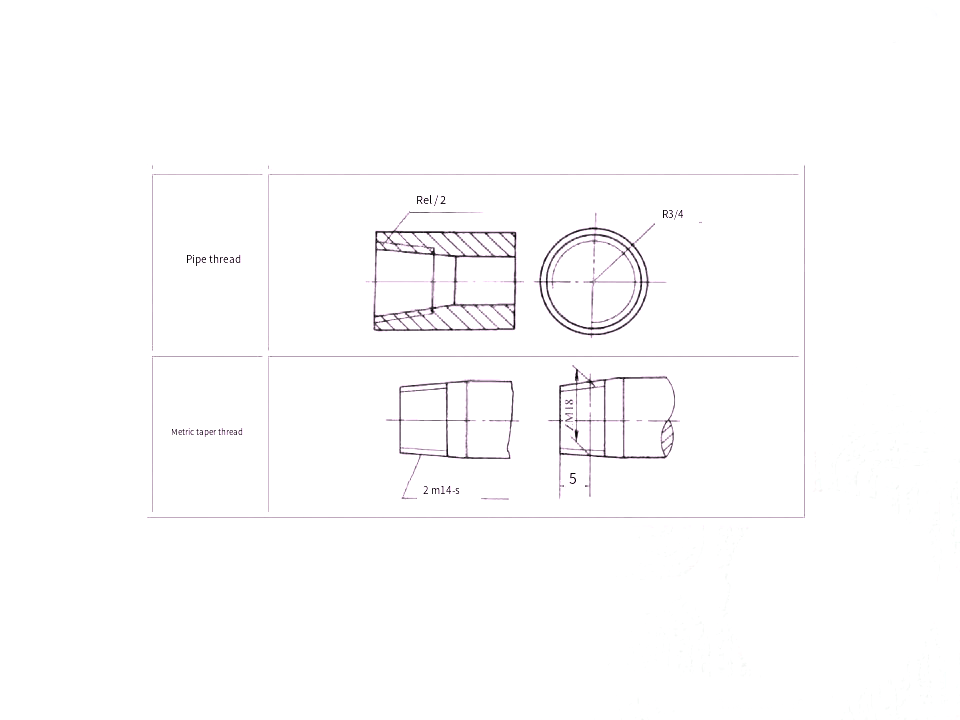

① Discrimination of thread typeGenerally, first observe its tooth type, the tooth type of ordinary thread is generally triangular, the top and bottom of the tooth have a small plane, the tooth Angle is 600; 550 non-sealed pipe thread is a triangle of 550, and the top and bottom of the tooth are round; The tooth Angle of the 550 sealed pipe thread is the same as that of the 550 unsealed pipe thread, but the imaginary cone tangent to the crown of the external thread or the bottom of the internal thread is 1:16 taper, the diameter at the end of the thread is small, and the diameter at the end of the thread is large; The shape and Angle of the 60° taper pipe thread are the same as that of the ordinary thread, but the imaginary cone with the tip of the external thread or the bottom of the internal thread is 1:16 taper, and the same as that of the 550 seal pipe thread: the shape Angle of the trapezoid thread and the serrated thread is consistent with its name. Therefore, as long as the characteristics of various threads are grasped, they can be identified smoothly, and if conditions are available, thread gauges can be used to measure them to help them identify correctly.

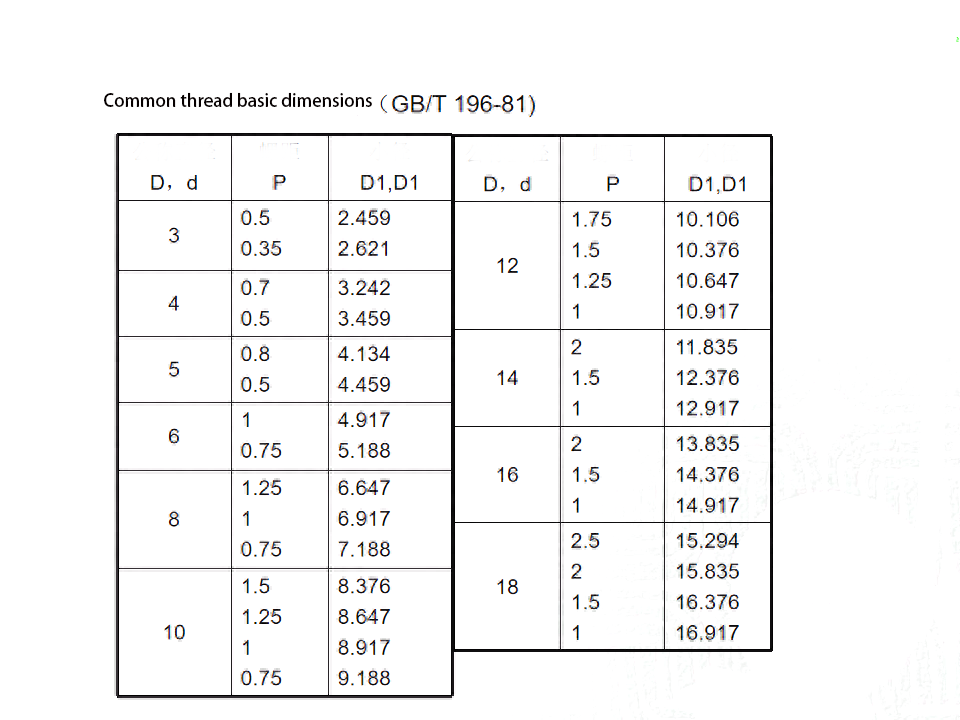

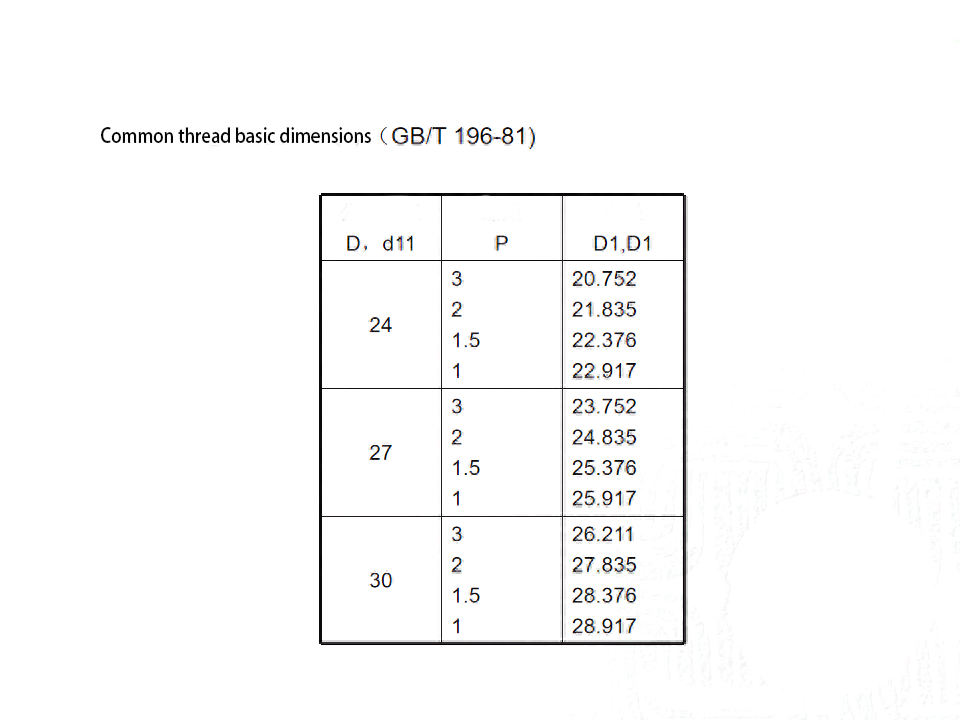

② Determination of screw pitchMeasuring tool: steel ruler or vernier caliperMeasuring method; External thread with steel ruler direct determination, as far as possible is multi-tooth determination, such as a test of 4 teeth, 5 teeth, 8 teeth, or even 10 teeth, a measurement of the number of teeth, measured the more accurate the pitch. Internal thread measurement is relatively difficult, it is best to use chalk or waste paper to print out the shape of the thread after the measurement is more accurate.

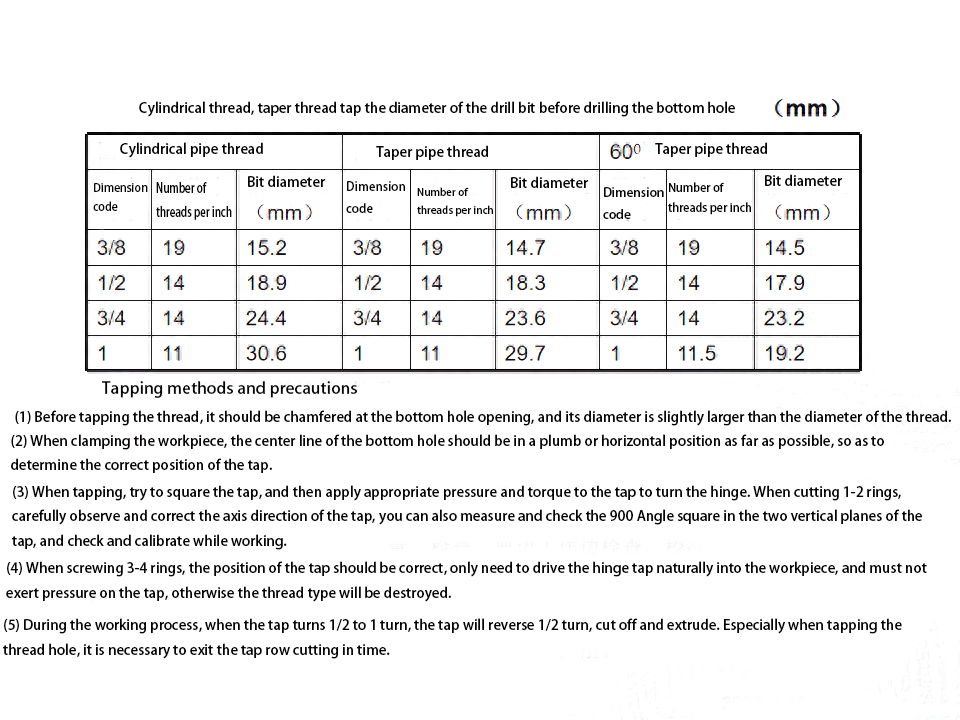

Tapping the thread

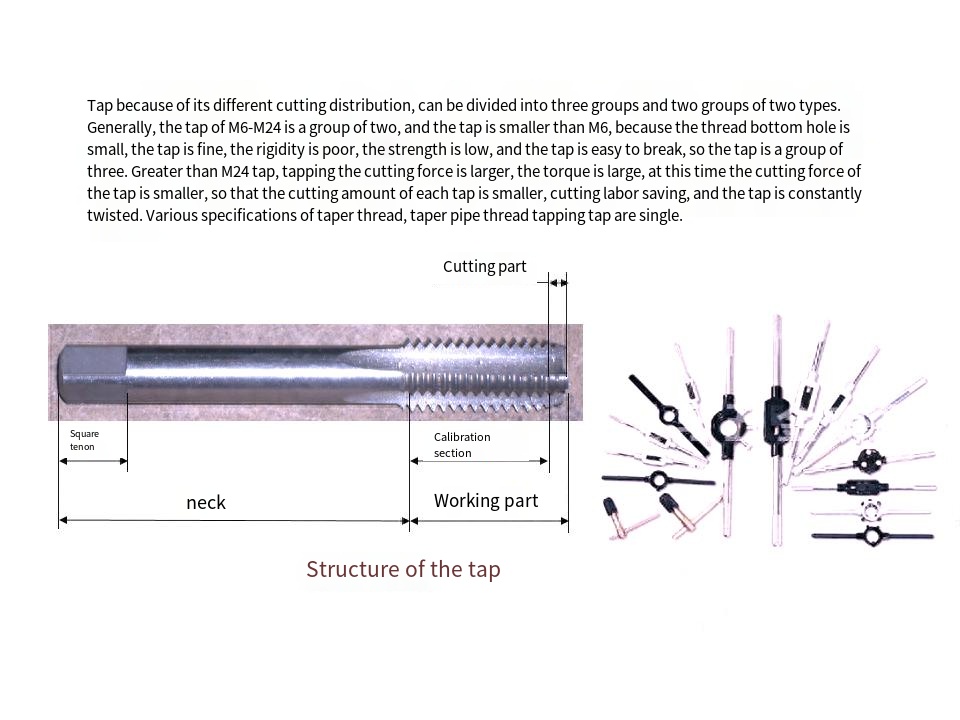

TapTap is a tool for processing internal threads, which is divided into two kinds of hand tap and machine tap. According to the tooth type can be divided into ordinary thread tap, cylindrical pipe thread tap and taper thread tap. Ordinary thread tap is divided into coarse teeth and fine teeth two kinds

(6) When you want to replace a tap, you should screw it in by hand until it can not be screwed in, and then use the hinge clamp to continue working, so as not to apply uneven pressure on the tap or shake damage the thread.

(7) When tapping the thread on the plastic material, oil or cutting fluid lubrication should be added to improve the processing quality of the surface of the thread hole, reduce cutting resistance and extend the service life of the tap.

(8) After the end of tapping, when the tap exits, it is best to remove the hinge bar and screw the tap by hand to ensure the quality of the screw hole.

(9) When tapping, such as the tap is broken in the screw hole, the following methods can be taken out.

① First remove the chips in the air, so as not to hinder the broken tap.

② If the tap is broken in the hole or near the hole, the narrow chisel or punch can be used to reach the chip containing slot of the broken tap, gently tap along the tangent direction of the exit, if necessary, and then tap in the reverse direction, so alternately reverse and positive direction, the broken tap can be withdrawn.

③ If the tap is broken in the hole, you can use the waste tap with square tenon screw on two nuts, with appropriate thick several steel wire through the nut, insert the broken tap chip slot, and then use a wrench to screw the square tenon in the exit direction, you can break the tap out.

④ If the broken tap is exposed outside the hole, a hexagon nut can be welded, and the screw nut can be turned out with a wrench.

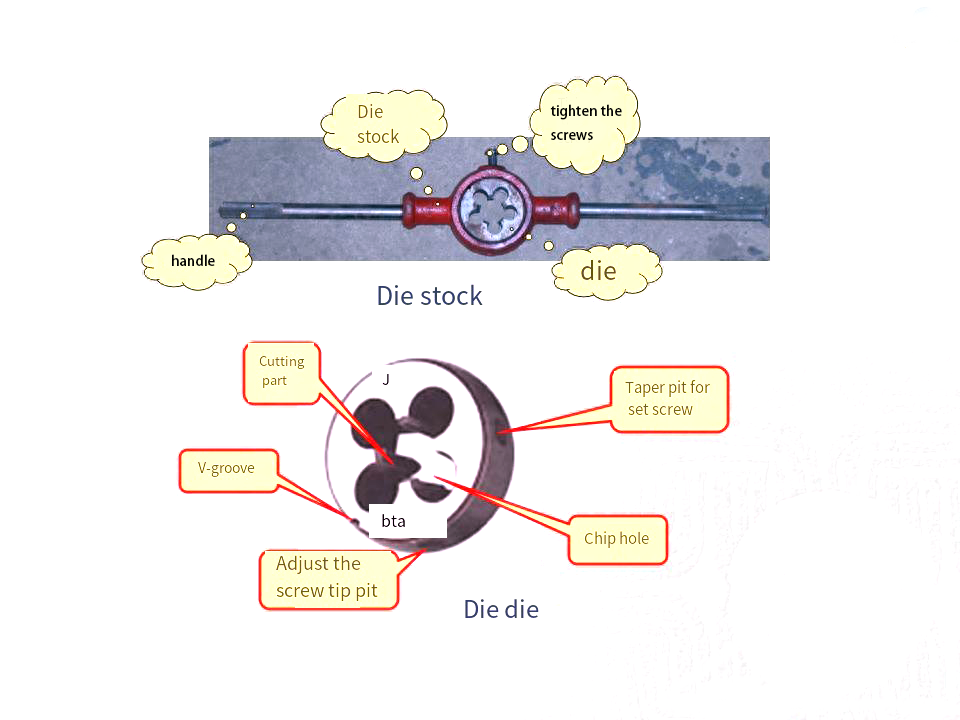

4, die and die frame

Die is a tool for processing external threads, which is composed of a cutting part, a calibration part and a row hole. The die above M3.5 has four cone pits and a V-shaped groove on the outer circle, and the two cone pits opposite the V-shaped groove can fix the die in the die frame, and hold it with two screws and transmit torque; The pyramidal pits on both sides of the V-shaped groove are used to adjust the die size.The die holder is the tool that holds the die.

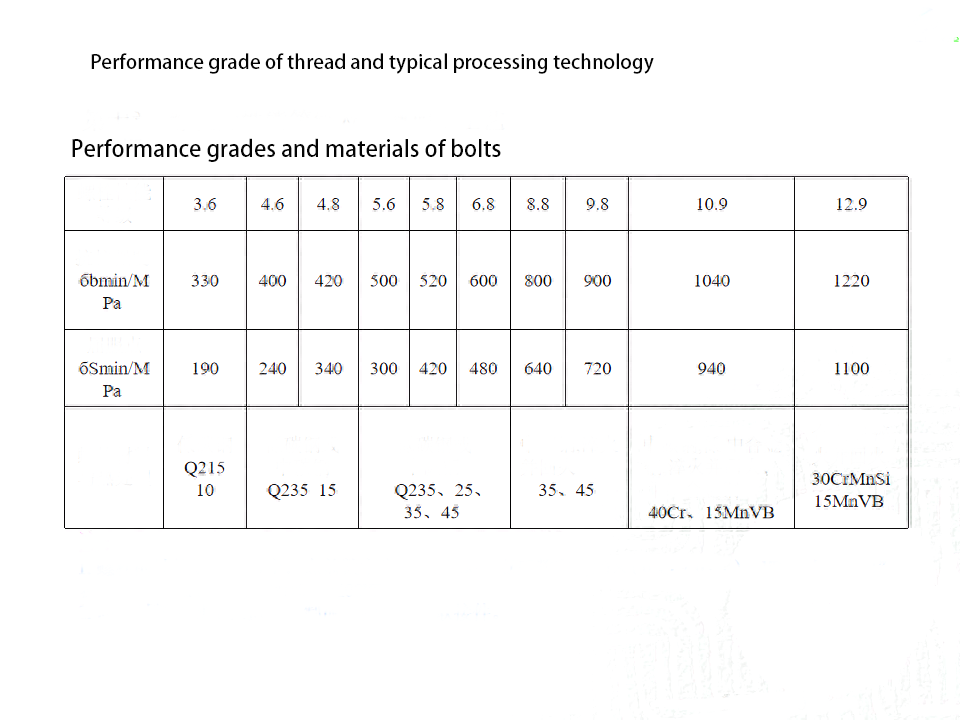

typical processing technology

① Nuts below grade 8: Disk unit → pickling → wire drawing → Molding → Tapping → surface treatment → Packaging ②8 grade nuts hot dip galvanizing: disk unit → pickling → wire drawing → Molding → Tapping → surface treatment → Packaging ③8 grade nuts: disk unit → annealing → pickling → wire drawing → Surface treatment → Packaging ④ Bolt: disk unit → annealing → pickling → wire drawing → Heading → Teeth rolling → Heat treatment → electroplating → packaging

Post time: Oct-18-2023