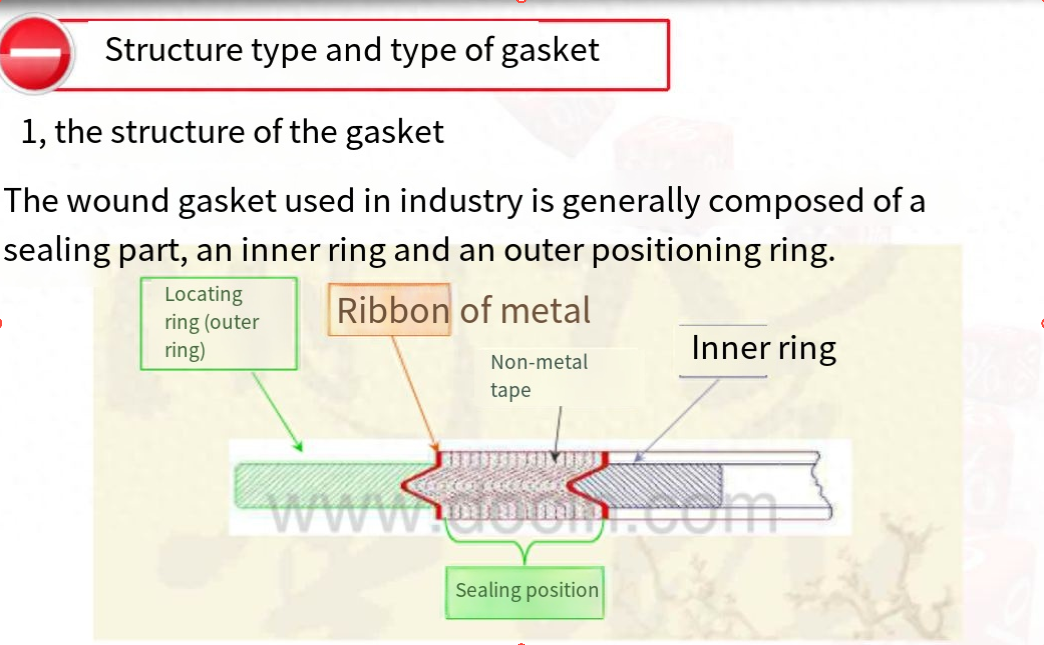

Non-metal tape

Itscommonly used non-metallic materials are, such as flexible graphite (<600 ° C), polytetrafluoroethylene (-200~260 ° C), fiber reinforced rubber based composite board.

Ribbon of Metal

StrapsShape: V, W, wavy, etcMaterial: 0.15~0.25 low carbon steel, stainless steel, copper and other corrosion resistant alloys, etc.Function: control the compression resilience of the gasket, sealing; Increase the overall stiffness of the gasket.

Inner ring

Principle: The inner ring is in contact with fluid, and its material should be resistant to corrosion of the sealing medium.

Materials: carbon steel, stainless steel, other corrosion resistant alloys, etc.

Function: To prevent the gap between the sealing part and the container or pipe flange to avoidThis gap interferes with the flow of fluid and the resulting fluid erosion of the gasket. When the internal fluid pressure and temperature are high, the internal fluid corrosion and abrasion are fierce, the fluid is prevented from remaining in the flange gap, the gasket size is large or the use of convex and concave flange and other occasions, the inner ring is set.

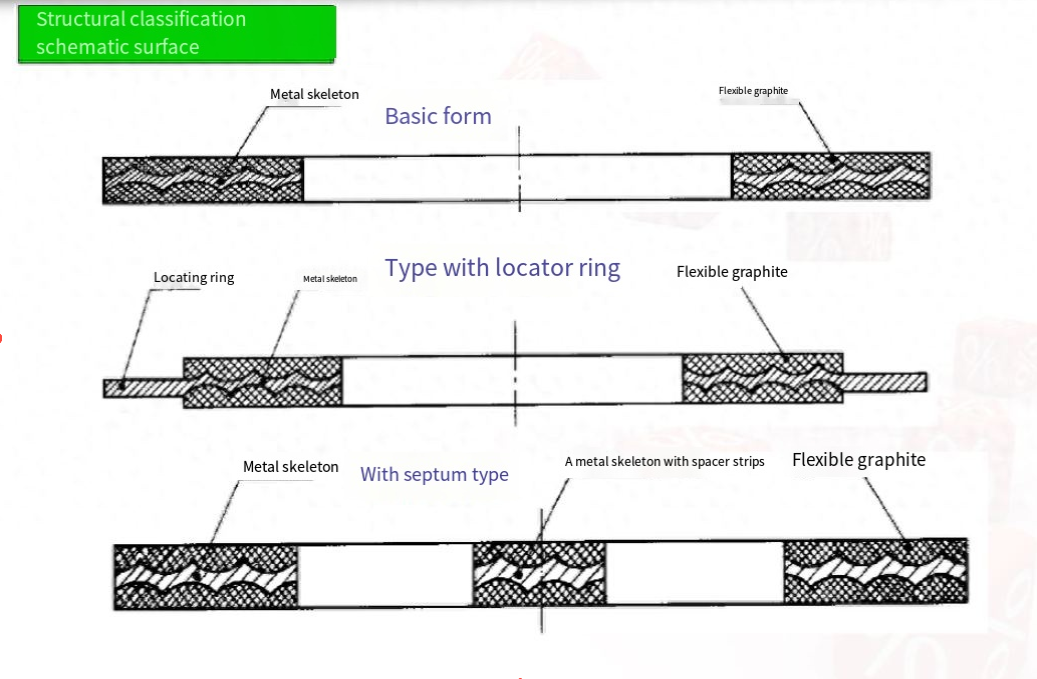

Locating ring (outer ring)

Function: reinforcing and correct positioning of the gasket body, preventing over-tight compression from losing the springback ability of the gasket and preventing the gasket from being loose.Material: The outer reinforcing ring or the outer ring material are solid metal, (such as carbon steel, stainless steel, other corrosion resistant alloys) the outer reinforcing ring is not in contact with the sealing medium, so it is not required to resist medium corrosion, so it is often made of carbon steel material.The outer reinforcing ring can also be made into a whole with sealing elements, such as metal toothed gasket and wave toothed composite gasket.

2, polytetrafluoroethylene gasket

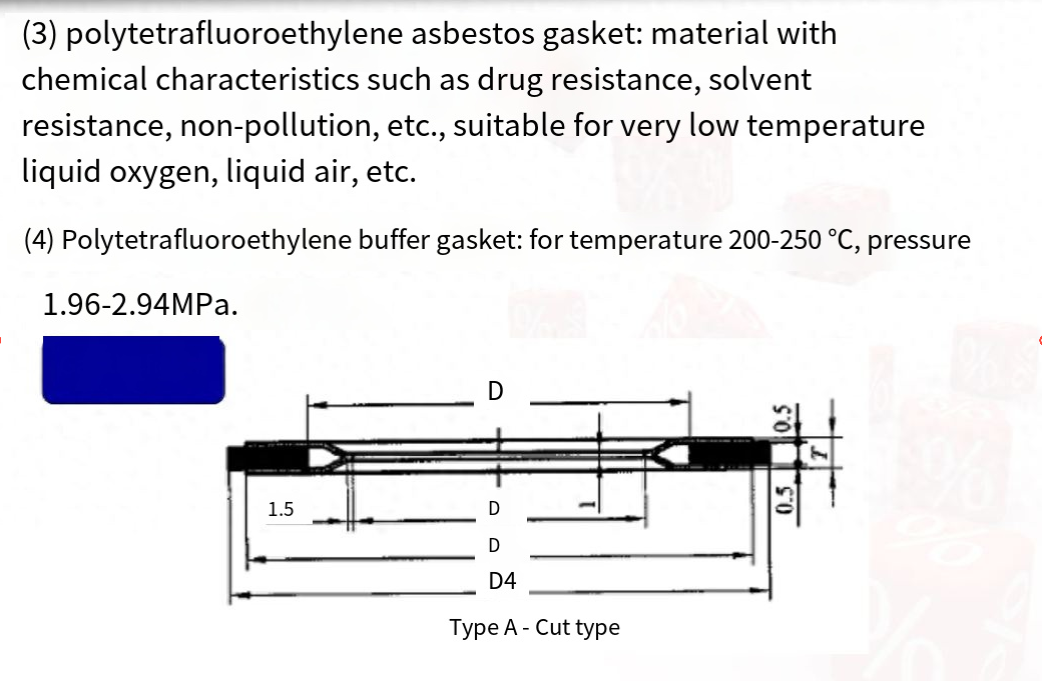

In the possible use of the temperature range (-180 — 250 ℃) can hardly be corroded by chemicals and solvents, but also can do anti-electrochemical corrosion pipe insulation gasket.Classification(1) Polytetrafluoroethylene flat gasket: generally suitable for convex and concave flange and flange with water line, not for wide flange. More used for corrosion resistance occasions. In order to achieve a good sealing effect, the gasket can be coated with teflon paste.(2) Polytetrafluoroethylene felt gasket: its chemical properties are the same as polytetrafluoroethylene flat gasket. But the leakage resistance, compression resistance than the PTFE flat gasket is superior, can be used for wide flange.The minimum preload specific pressure y of the seal is 11.77-19.6MPa, the use temperature is 200 ℃, the pressure is about 0.98MPa.

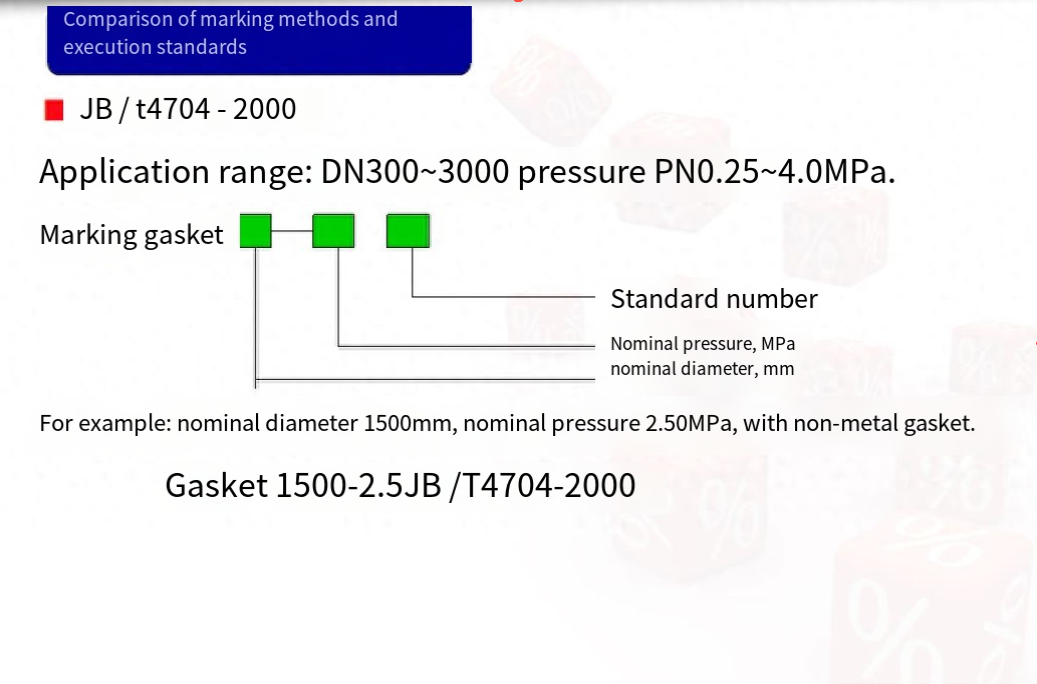

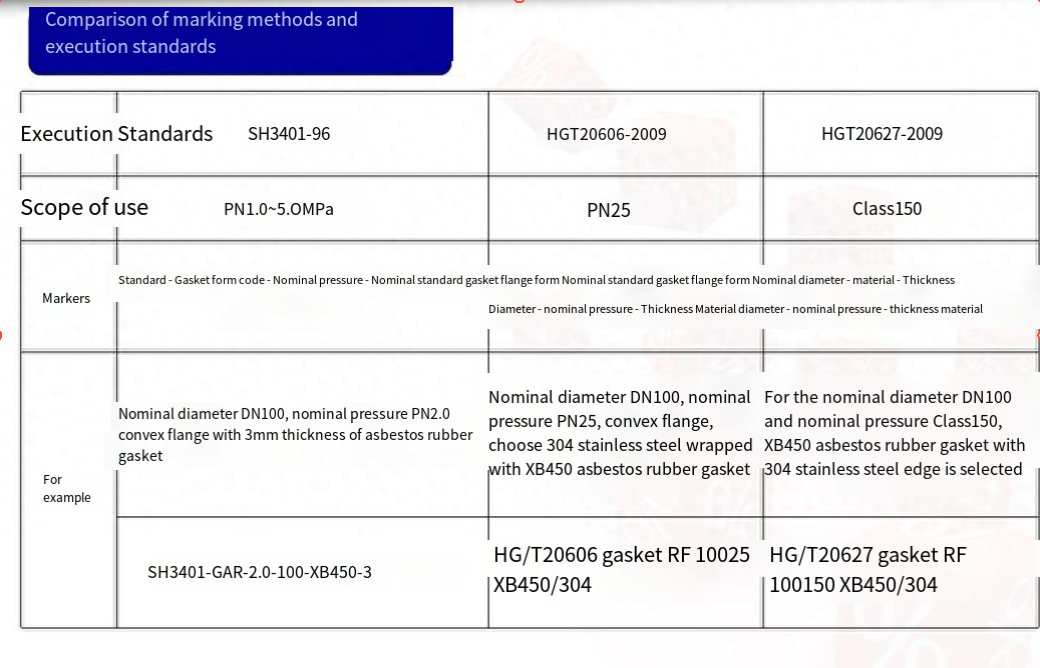

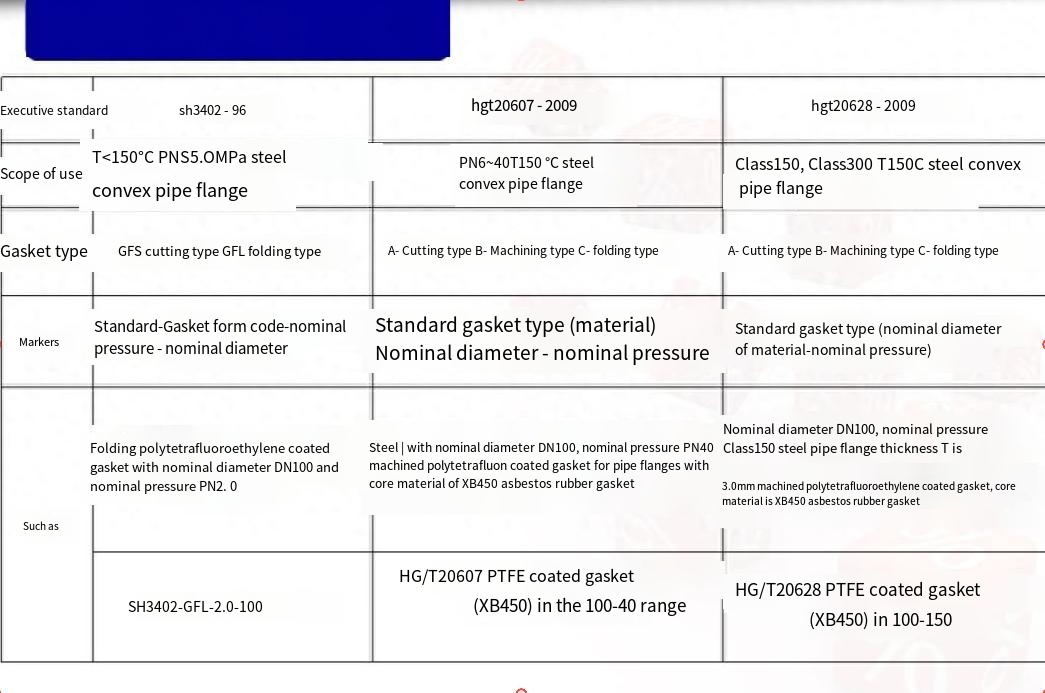

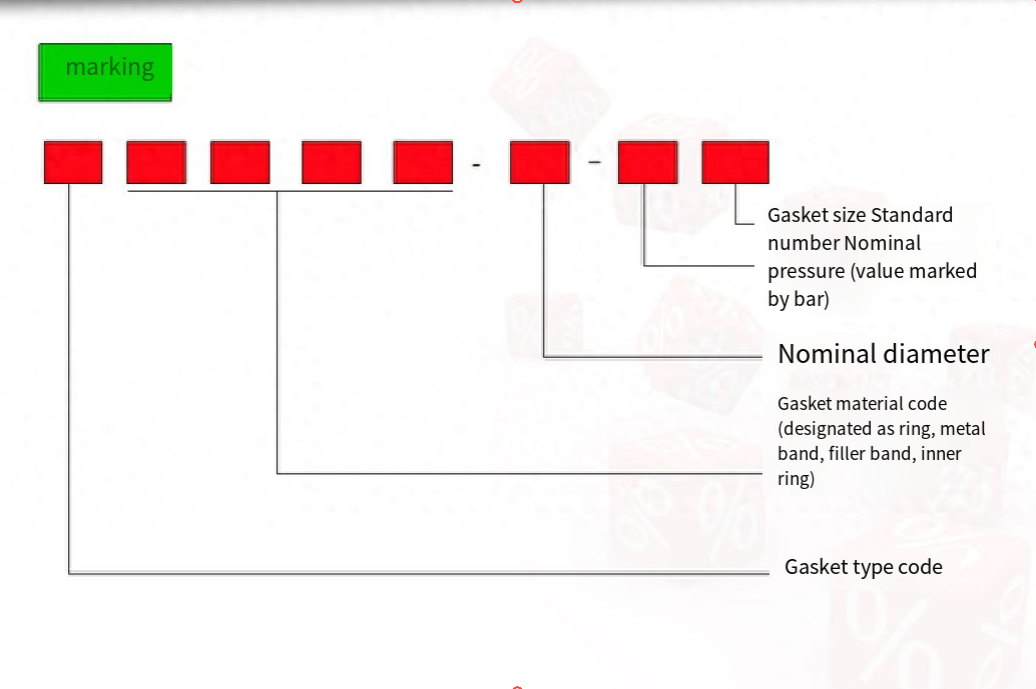

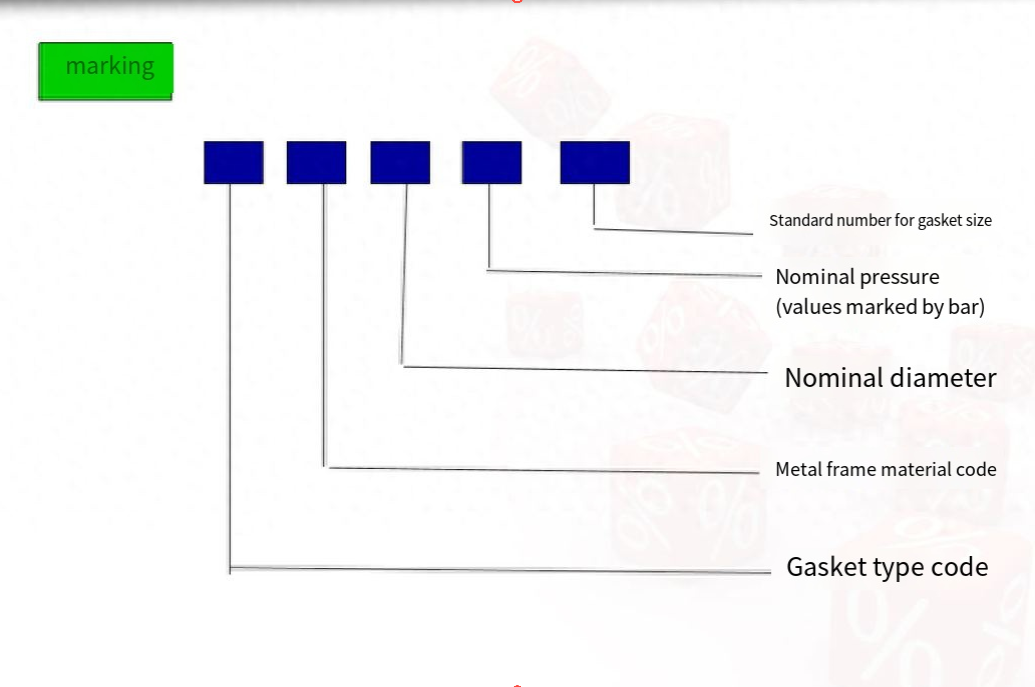

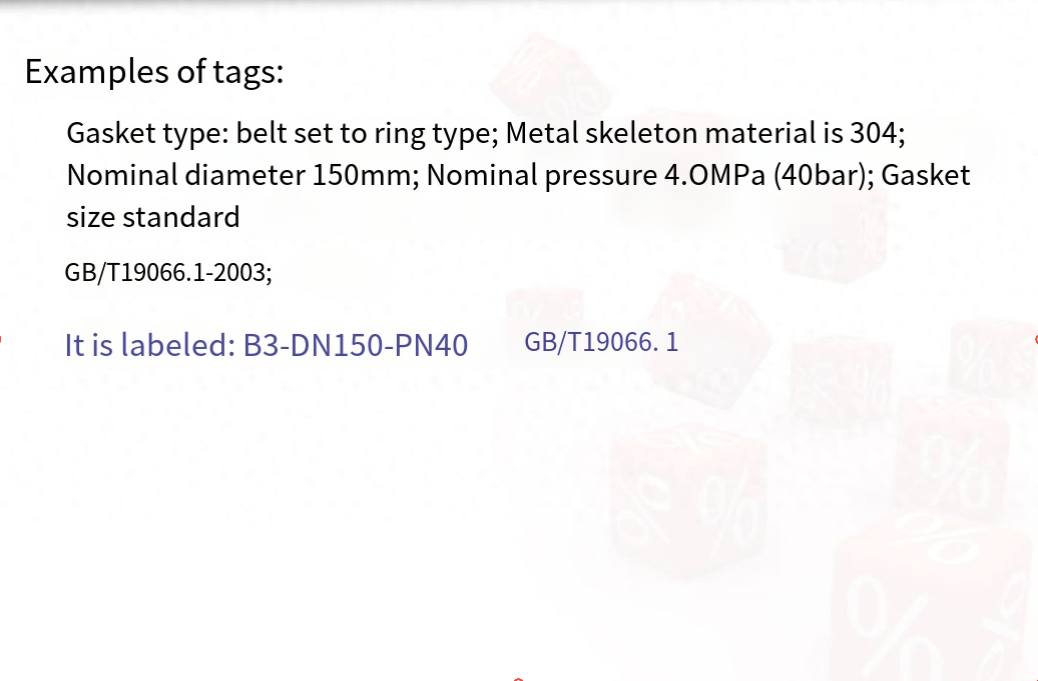

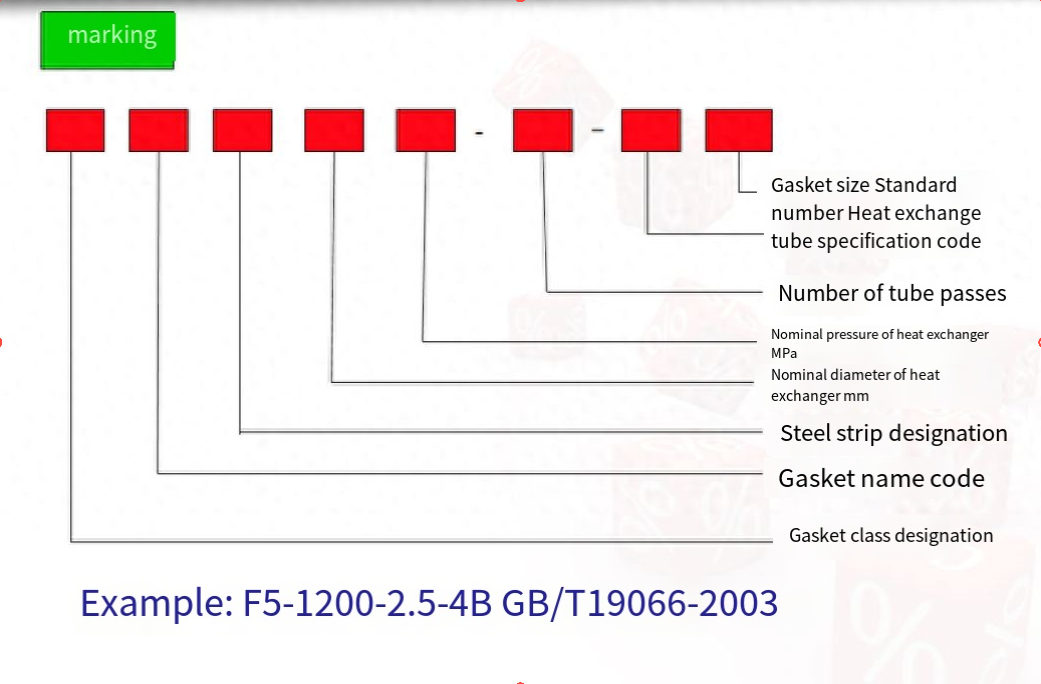

Examples of tags:

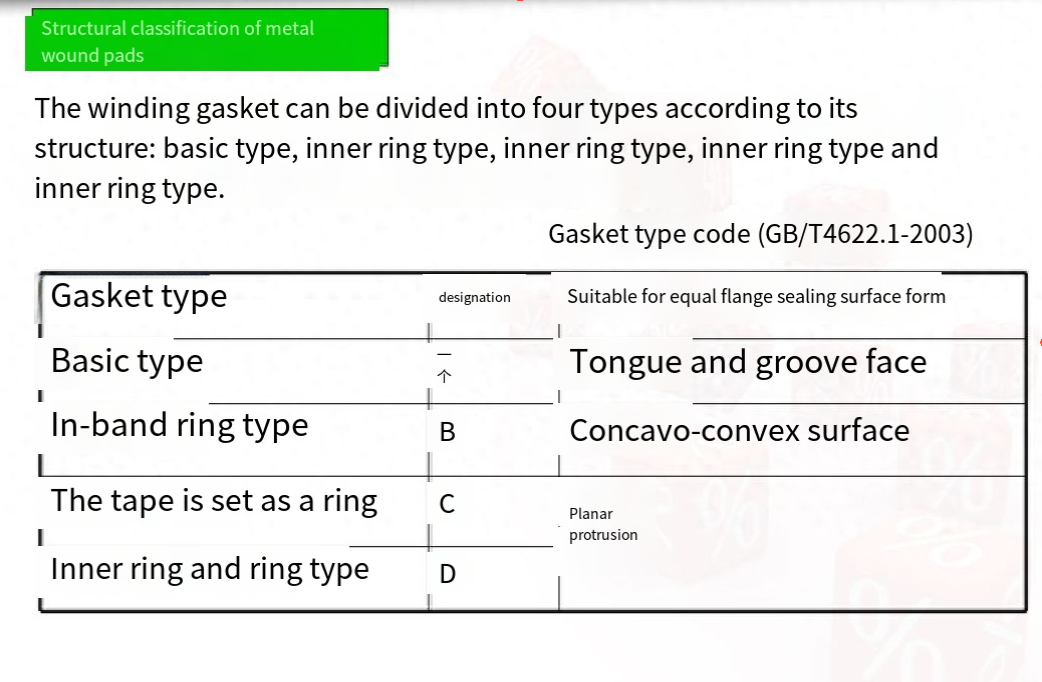

Gasket type: with inner ring and set as ring type; The ring material is low carbon steel, the metal belt material is OCr18Ni9; Nominal diameter 150mm; Nominal pressure 4.OMPa(40bar) ; Gasket size standard GB/T4622.2-2003;

It is labeled: D 1222-DN150-PN40 GB/T4622.2

Type of gasket: basic type; Gasket material: metal belt material is 0Cr18Ni9,The filling belt material is flexible graphite; Nominal diameter 150mm; Nominal pressure 4.OMPa(40bar) ; Gasket size standard GB/T4622.2-2003;

It is marked as: A 0220-DN150-PN40 GB/T4622.2

Post time: Sep-06-2023