On November 10th, the 6th China International Import Expo officially concluded. Over the past six years, domestic and foreign enterprises have launched approximately 2440 new products, technologies, and services at the CIIE, highlighting the importance of the Chinese market and global confidence in the Chinese economy. This year's CIIE has brought many new highlights to the manufacturing industry as one of the highlights of the exhibition, with various top-level exhibits showcasing the "light of technology" while also pointing out the future development direction for the industry.

The technical equipment exhibition area includes specialized areas such as digital industrial automation, integrated circuits, energy low-carbon and environmental protection technology, artificial intelligence, as well as parts, digital printing and optical technology, metal cutting, sheet metal, measurement, and other sectors. It gathers many global leading enterprises in the manufacturing industry's segmented fields, showcasing cutting-edge technology and high-end equipment. Integrating the development concept of "high-end+intelligent+green" in various zones around the development strategy of key industries such as dual carbon, digitalization, integrated circuits, and artificial intelligence.

The new energy equipment industry is an important guarantee and support for China to achieve the dual carbon goal. It is expected that in the future, the annual added value of China's new energy equipment manufacturing industry will reach over trillion yuan, with an industrial scale of over 4 trillion yuan.

It is understood that the automotive exhibition area is centered around the theme of "co creating a better future for mobile travel" and is divided into three major sections: vehicle and new energy vehicles, smart travel zone, and multimodal transportation. Fifteen multinational car companies, including BMW, Mercedes Benz, General Motors, Volkswagen, Hyundai, and other automotive component giants such as Bosch and Mobis, gather here to bring the latest products, technologies, and solutions for the future automotive industry.

Volkswagen, General Motors, Mercedes Benz, and others all showcased the latest new energy vehicles at the exhibition site. In addition to electric vehicles, clean energy "hydrogen fuel cell vehicles" are also one of the cutting-edge technologies that car manufacturers are eager to showcase this year. BMW, Hyundai, and Toyota have all placed "hydrogen fuel cell models" in a prominent position for battery cars.

Hydrogen fuel cells that can truly achieve zero emissions are widely regarded. With the introduction of more and more supportive policies, the commercial application of hydrogen fuel cell vehicles is accelerating. According to public sources, the cumulative ownership of fuel cell vehicles in China has exceeded 13000, ranking third in the world. Among them, the number of fuel cell commercial vehicles ranks first in the world, and the domestic hydrogen fuel cell market is currently being nurtured.

As an industry with a long industrial chain, transitioning to intelligent electrification is not only a strategy for vehicle manufacturers, but also a strategy for upstream component companies in the automotive industry chain to "showcase their strengths" in terms of products and technology. Mobis wearable device M. Brain, Unity China's "Unity Engine Car Kit"... Intelligent car machines are the trend, and the related market has a promising future.

Manufacturing Trends:

From the exhibits related to the manufacturing industry at this year's CIIE, we can also see that whether it is technical equipment or automobiles, they are basically centered around three major themes: high-end, intelligent, and green. These three major themes also indicate the future development direction of China's manufacturing industry. China is a major manufacturing country. In 2022, the added value of China's manufacturing industry accounted for 27.7% of GDP, and the scale of China's manufacturing industry has ranked first in the world for 13 consecutive years.

However, objectively speaking, although China's manufacturing industry as a whole is large, it is not strong. There are prominent issues in the industry, such as weak independent innovation capabilities, failure to master key core technologies, and low green and low-carbon development capabilities. To truly become a manufacturing powerhouse, one must have a complete high-end manufacturing industry chain!

Fastener Industry: Seizing the Opportunity of High end Manufacturing Industry

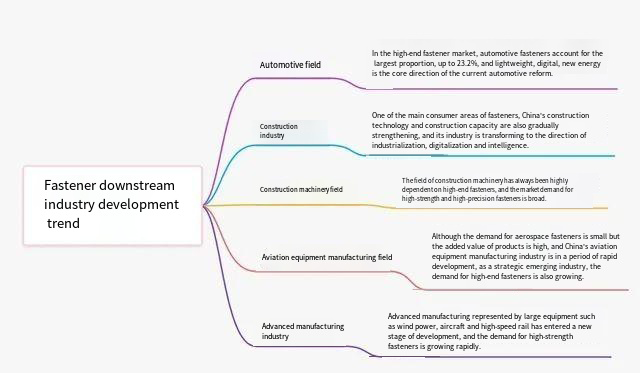

As an indispensable part of the development of the manufacturing industry, the fastener industry will also move towards high-end, intelligent, and green development in the future, ushering in new opportunities in the wave of transformation in fields such as smart cars, energy internet, and industrial

internet.

That is to say, the fastener industry needs to achieve digital intelligence construction, closely follow the development of its downstream industries, optimize process technology, improve product quality, and meet the high-end and refined needs of downstream industries.

In the automotive industry, new energy vehicles require a large number of high-strength fasteners compared to traditional vehicles, and there are also differences in materials, structures, and processes. In the connection design of new energy vehicle bolts/studs, not only should the size, material, tolerance level, mechanical properties, etc. of the bolts be fully considered, but also the application environment of the bolts, such as temperature (high/low temperature), vibration, alternating cold and hot, corrosiveness, and other environmental factors should be fully considered. This requires fastener enterprises to carry out corresponding technological upgrades.

At present, there has been an oversupply of ordinary standard fasteners in China, but high-end fastener products are in short supply and still need to rely on imports. If China wants to move towards becoming a 'manufacturing powerhouse', it is impossible for every small screw to rely on imports! Market demand is the best driving force. With the continuous expansion of high-end market demand, the transformation and upgrading of the fastener industry is inevitable. What we screwdrivers need to do is to follow the trend of the times, seize opportunities, and help China's manufacturing industry "grow stronger"!

Post time: Nov-14-2023