With the increasing diversity of modern people’s decoration styles, more and more household items need to be fixed on the wall. If you always find a worker, it is not only troublesome, but also expensive. In fact, in our daily lives, most of the household items that are not too heavy can be easily and easily handled by expanding screws at home. Today, let’s learn about the magical expansion screw together.

The basic principle of expansion screws

The so-called expansion screw is actually a type of nail, but its load-bearing capacity is much stronger than ordinary nails.

An expansion bolt is a type of fastener consisting of a head and a screw (a cylindrical body with external threads), which needs to be matched with a nut to tighten and connect two parts with through holes. This type of connection is called bolt connection. If the nut is unscrewed from the bolt, it can separate the two parts, so bolt connection is a detachable connection.

Its structure is also very simple, consisting of two parts: screws and expansion pipes. The working principle is not complicated, it is to drive them together into the wall and then lock the nut. When the nut is locked inward, the screw will pull outward, which will then expand the iron sheet expansion pipe and clamp it into the wall, playing a firm fixing role.

Classification of expansion screws

According to the material, there are two types of expansion bolts: plastic expansion and stainless steel expansion.

Plastic expansion

Plastic expansion is equivalent to a substitute for traditional wooden wedges. There are 6 regular models available × 30,8 × 40. These two models are generally used for hanging items in kitchens and bathrooms, such as towel hanging rods, tool hanging rods, cross stitch hanging, etc. Some extended 8×60, 8×80, 8×100, 10×80, and 10×100 are mainly used for hanging heavy objects, such as LCD TVs, range hoods, etc.

Metal expansion bolt

The use of metal expansion bolts varies depending on the actual situation of the wall. There are generally several specifications: 6 * 60, 6 * 80, 6 * 120, and 6 * 150.

According to the appearance, stainless steel expansion can be divided into external expansion, external hexagonal internal expansion, expansion hook, ring expansion, etc.

Advantages of expansion screws

Strong fixation force: Due to the special design of the expansion screw, it can generate strong expansion force when tightening, tightly grasping the wall, and providing extremely high fixation force.

Strong adaptability: Expansion screws can adapt to various wall materials, whether it is brick walls, gypsum board walls, or concrete walls, and can play a good fixing effect.

Easy installation: Compared to ordinary screws, the installation process of expansion screws is relatively simple and does not require special tools or skills.

High safety: Since expansion screws can be deeply fixed in the wall, using expansion screws for fixation is safer than using regular screws.

Precautions for using expansion bolts

1. Drilling depth: In specific construction, it is best to have a depth of about 5 millimeters deeper than the length of the expansion pipe. As long as it is greater than or equal to the length of the expansion pipe, the length of the internal expansion bolt left underground is equal to or less than the length of the expansion pipe;

2. The requirement for internal expansion bolts on the ground is, of course, the harder the better. This also depends on the stress situation of the object you need to fix. The stress strength installed in concrete (C13-15) is five times that of brick;

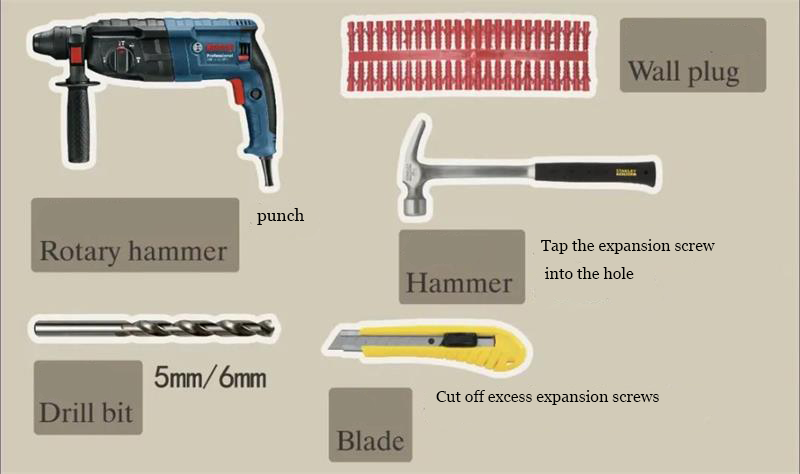

3. After correctly installing an M6/8/10/12 inner expansion bolt in concrete, its ideal maximum static stress is 120/170/320/510 kilograms, respectively. The installation method of the inner expansion bolt is not very difficult, and the specific operation is as follows; Firstly, select an alloy drill bit with the same diameter as the expansion screw tightening ring (pipe), install it on the electric drill, and then perform wall drilling. The depth of the hole should be the same as the length of the bolt, and then lower the expansion screw kit into the hole together. Remember not to unscrew the screw cap to prevent the bolt from falling into the hole and not being easy to take out when drilling deeper. Then, tighten the screw cap 2-3 times and feel that the internal expansion bolt is tight but not loose before unscrewing the screw cap.

Post time: Nov-21-2023