At 11:14 am on October 26, 2023, the Shenzhou 17 manned spacecraft carrying astronauts ignited and took off from the Jiuquan Satellite Launch Center after precise planning and collaboration. This successful launch not only marks the glorious achievements of China’s aerospace industry in 30 successful launches, but also highlights the great role of a small component.

Behind China’s magnificent aerospace achievements lies a silent hero – wedge-shaped threaded fasteners. These small threaded parts play an indispensable role in the aerospace industry, playing a crucial role in safeguarding the safety of aerospace and realizing China’s grand aerospace dream.

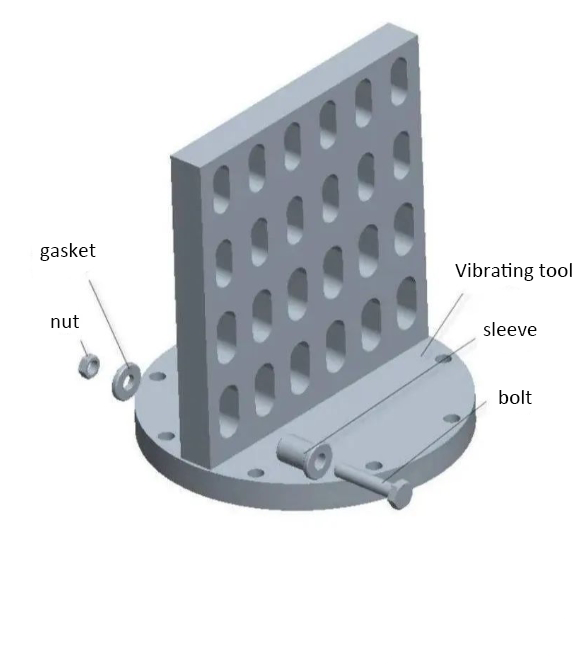

The working environment of aerospace products is extremely harsh, with a large number of fasteners. Once the fastener loosens during severe vibration, it may cause equipment damage and even cause major accidents. To solve this problem, wedge-shaped threads were born. Let’s take a look at this small thread together.

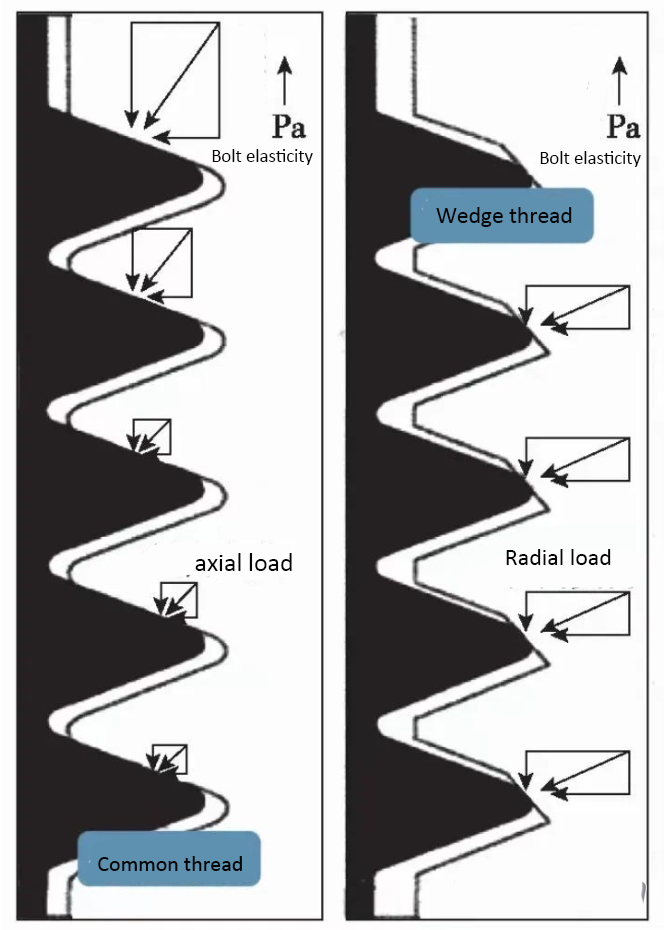

The wedge thread adopts a 30 ° wedge bevel thread profile, which has significantly better anti loosening performance than ordinary threads. When the bolt and nut are tightened against each other, the bolt tooth tip will firmly embed into the wedge-shaped slope inside the nut, generating a greater locking force than regular threads.

As early as 1977, the wedge-shaped inclined plane anti loosening technology had been adopted by the US military and patented. Chinese experts have also conducted research on wedge threads, especially for wedge thread fasteners for aerospace purposes. Research data shows that under working vibration loads, wedge threads have a higher anti loosening effect.

The vibration test results showed that the ordinary threads almost immediately became loose, while the wedge-shaped threads maintained their expected self-locking ability during the test.

In order to ensure the standardization of wedge shaped threads, the country has also formulated relevant standards – GB/T 37462-2019 “30 degree wedge shaped anti loosening threads”. The measurement method of wedge-shaped threads is different from ordinary threads, using the scanning method, which is more accurate, convenient, and easy to operate.

Wedge shaped threads, although small, play a huge role in China’s aerospace industry. They are indispensable partners on the path of aerospace, providing solid support for our aerospace dream.

Post time: Nov-08-2023